Automatic hydraulic steel strand cutter

A cutter and hydraulic steel technology, which is applied in the field of automatic hydraulic steel strand cutter, can solve the problems of inability to cut steel strands, large volume and difficult handling, discounted cutting effect, etc., to achieve convenient and accurate cutting, structural Simple, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

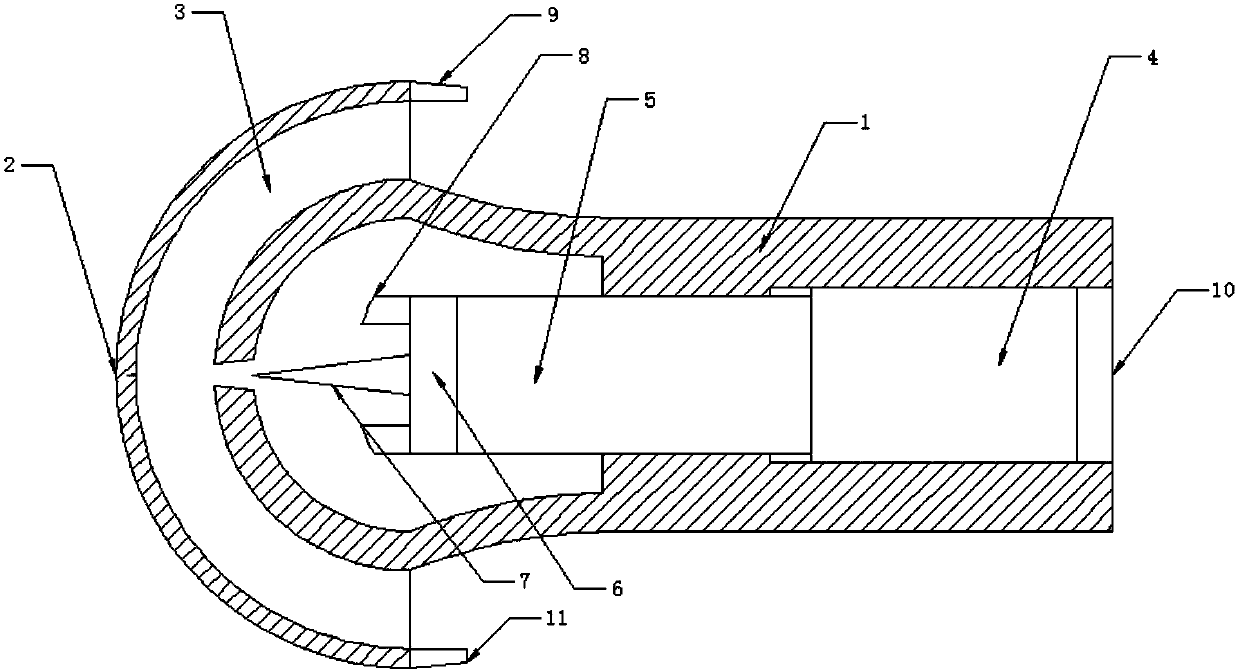

[0009] Such as figure 1 As shown, the present invention is an automatic hydraulic steel strand cutter, comprising a cutter body 1, the cutter body 1 is a hollow structure, one end of the cutter body 1 is arc-shaped, and the arc-shaped end of the cutter body 1 is provided with Stranded wire cover 2, the bending radian of the twisted wire cover 2 is the same as that of the curved end of the cutter body 1, a twisted wire channel 3 is formed between the cutter body 1 and the twisted wire cover 2, and a Hydraulic cylinder 4, the output end of the hydraulic cylinder 4 is provided with a booster block 5, the side wall of the booster block 5 is attached to the inner wall of the cutter body 1, and the free end of the booster block 5 is provided with a connecting piece 6, the connecting piece The center of the free end of 6 is provided with a cutting knife 7, the top center of one arc-shaped end of the cutter body 1 is provided with a hole, the free end of the connector 6 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com