A method for removing low molecular weight device and producing methyl silicone oil with a viscosity of 30-1000000cs

A production method and technology for methyl silicone oil are applied in the field of high-efficiency production of 30-1,000,000cs high-purity methyl silicone oil, which can solve the problems of low efficiency of methyl silicone oil, rising production costs, and low efficiency in removing low-efficiency, and achieve production system safety and production efficiency. High and reduced production time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

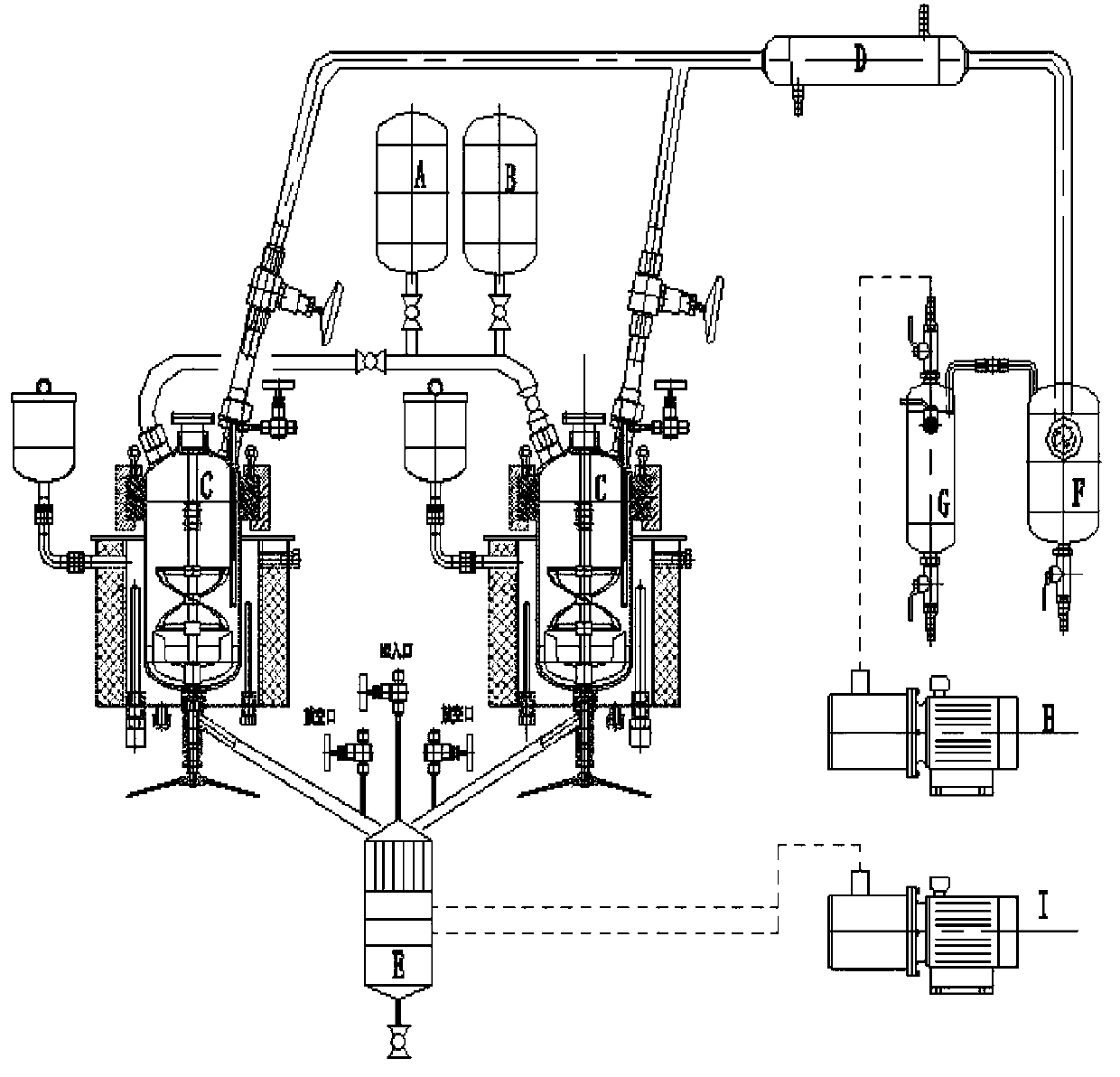

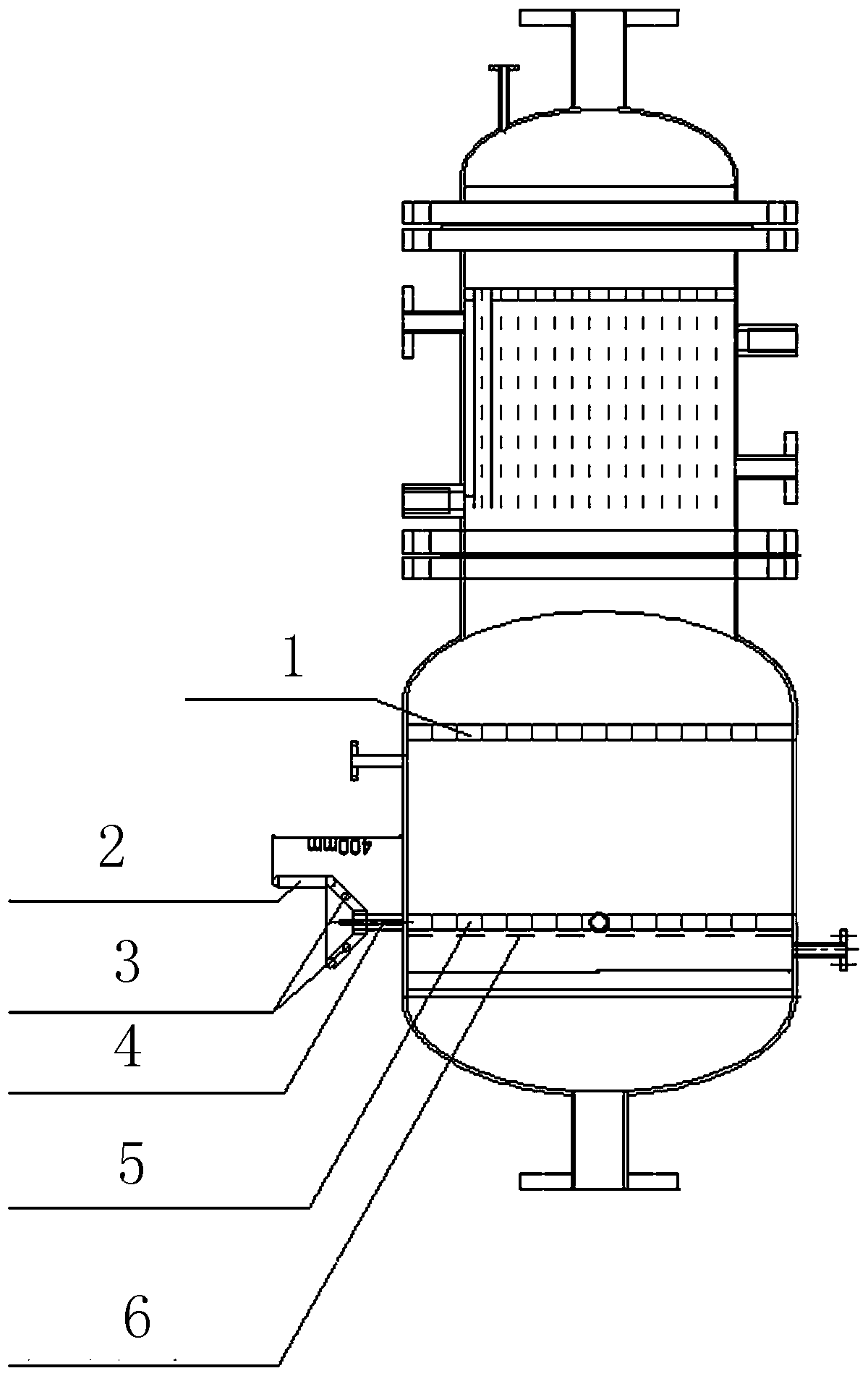

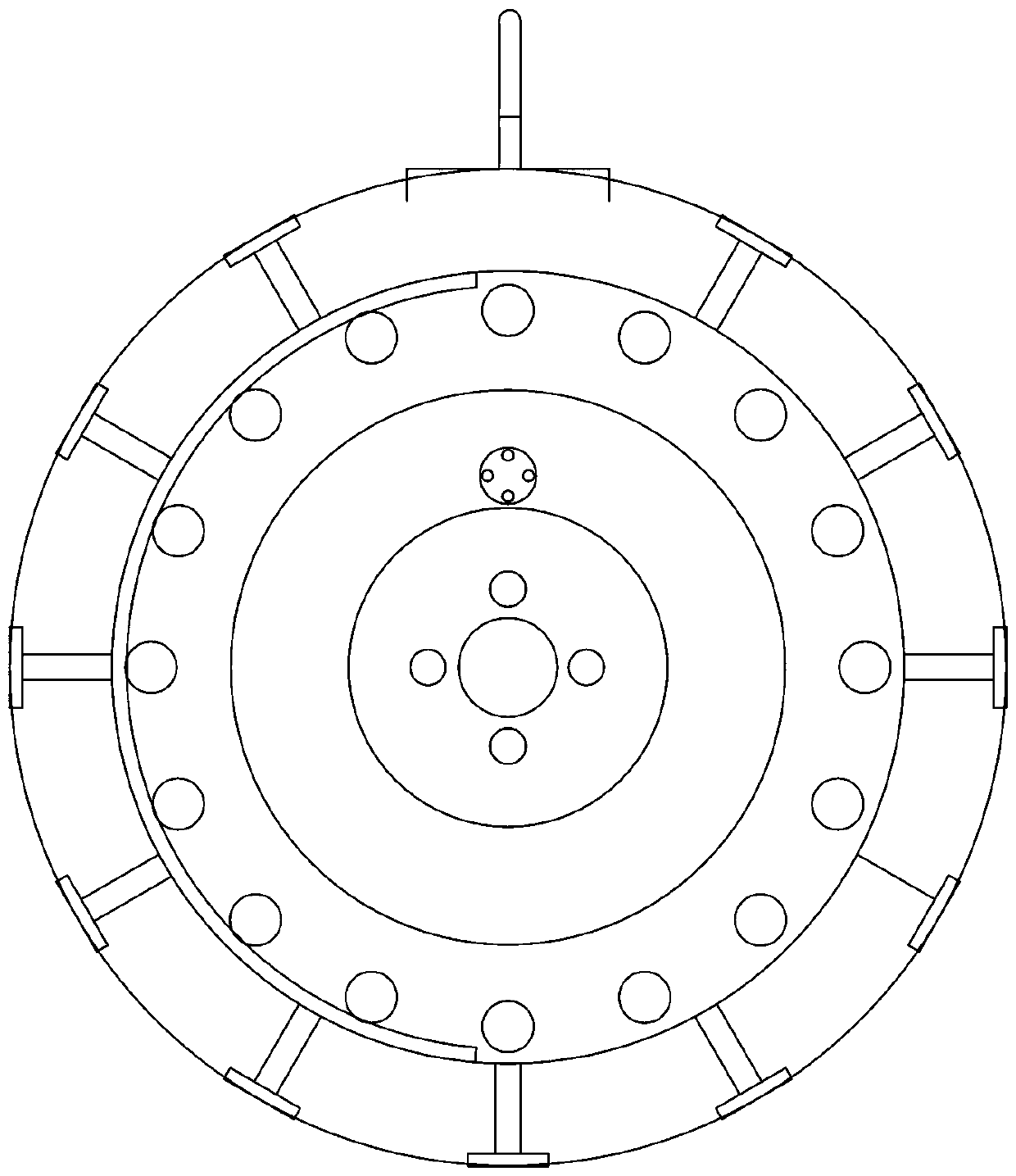

[0024] Add 2100Kg DMC to the stainless steel reaction kettle, start stirring and heat up, dehydrate at 80±5°C, vacuum degree -90kPa for 1h until there is no liquid in the sight glass. 300 Kg parts by weight of MDM were added after the vacuum was released. Raise the temperature to 120°C, then add 0.045Kg of catalyst to the stainless steel reaction kettle (the catalyst is: tetramethylammonium hydroxide alkali gel, put the above weight of tetramethylammonium hydroxide into 5Kg of DMC, stir at 130°C for about 1.5 hours prepared), continue to raise the temperature to 150°C, carry out polycondensation equilibrium reaction for 2.5h under the conditions of normal pressure and stirring speed of 150r / min. After the polymerization is completed, put the material into a special delowering device (before pressing into the delowering device, the second layer of flower board drawing and flashing plate must be placed in a horizontal position and locked with bolts. After opening the first layer...

Embodiment 2

[0026] Add 1000Kg D3 and 1100Kg D4 into the stainless steel reaction kettle, start stirring and raise the temperature, dehydrate at 80±5℃, vacuum degree -90kPa for 1h until there is no liquid in the sight glass. 240 Kg parts by weight of MDM were added after the vacuum was released. Raise the temperature to 120°C, then add 0.042Kg of catalyst to the stainless steel reaction kettle (the catalyst is: tetramethylammonium hydroxide alkali gel, put the above weight of tetramethylammonium hydroxide into 5Kg of DMC, stir at 130°C for about 1.5 hours prepared), continue to raise the temperature to 145°C, and carry out polycondensation equilibrium reaction for 2.5h under the conditions of normal pressure and stirring speed of 100r / min. After the polymerization is completed, put the material into a special delowering device (before pressing into the delowering device, the second layer of flower board drawing and flashing plate must be placed in a horizontal position and locked with bolt...

Embodiment 3

[0028]Add 800Kg D3 and 1300Kg D5 into the stainless steel reaction kettle, start stirring and raise the temperature, dehydrate at 82°C and vacuum degree -90kPa for 1h until there is no liquid in the sight glass. 160 Kg parts by weight of MDM were added after the vacuum was released. Raise the temperature to 125°C, then add 0.04Kg of catalyst to the stainless steel reaction kettle (the catalyst is: tetramethylammonium hydroxide alkali gel, put the above weight of tetramethylammonium hydroxide into 5Kg of DMC, stir at 130°C for about 1.5 hours prepared), continue to raise the temperature to 148°C, and carry out polycondensation equilibrium reaction for 2.5h under the conditions of normal pressure and stirring speed of 200r / min. After the polymerization is completed, put the material into a special delowering device (before pressing into the delowering device, the second layer of flower board drawing and flashing plate must be placed in a horizontal position and locked with bolts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com