A pickling tank for steel pipe sludge collection

A technology of pickling tank and collecting tank, applied in the field of pickling tank, can solve problems such as unfavorable workshop environment, increase workshop danger, affect pickling performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

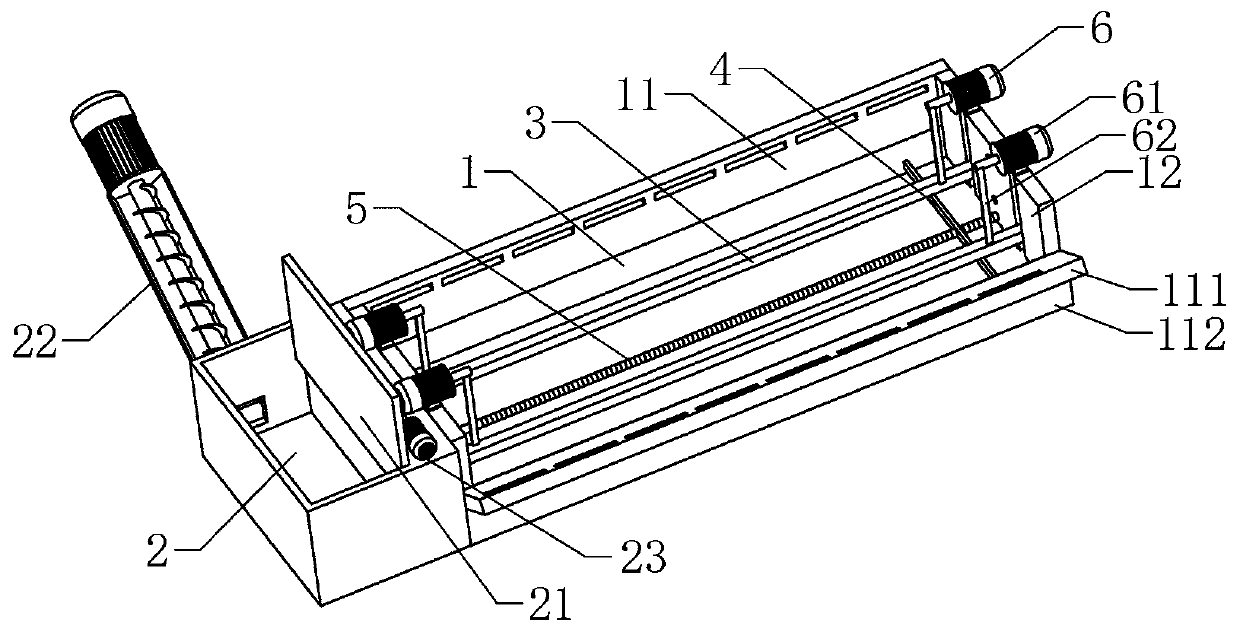

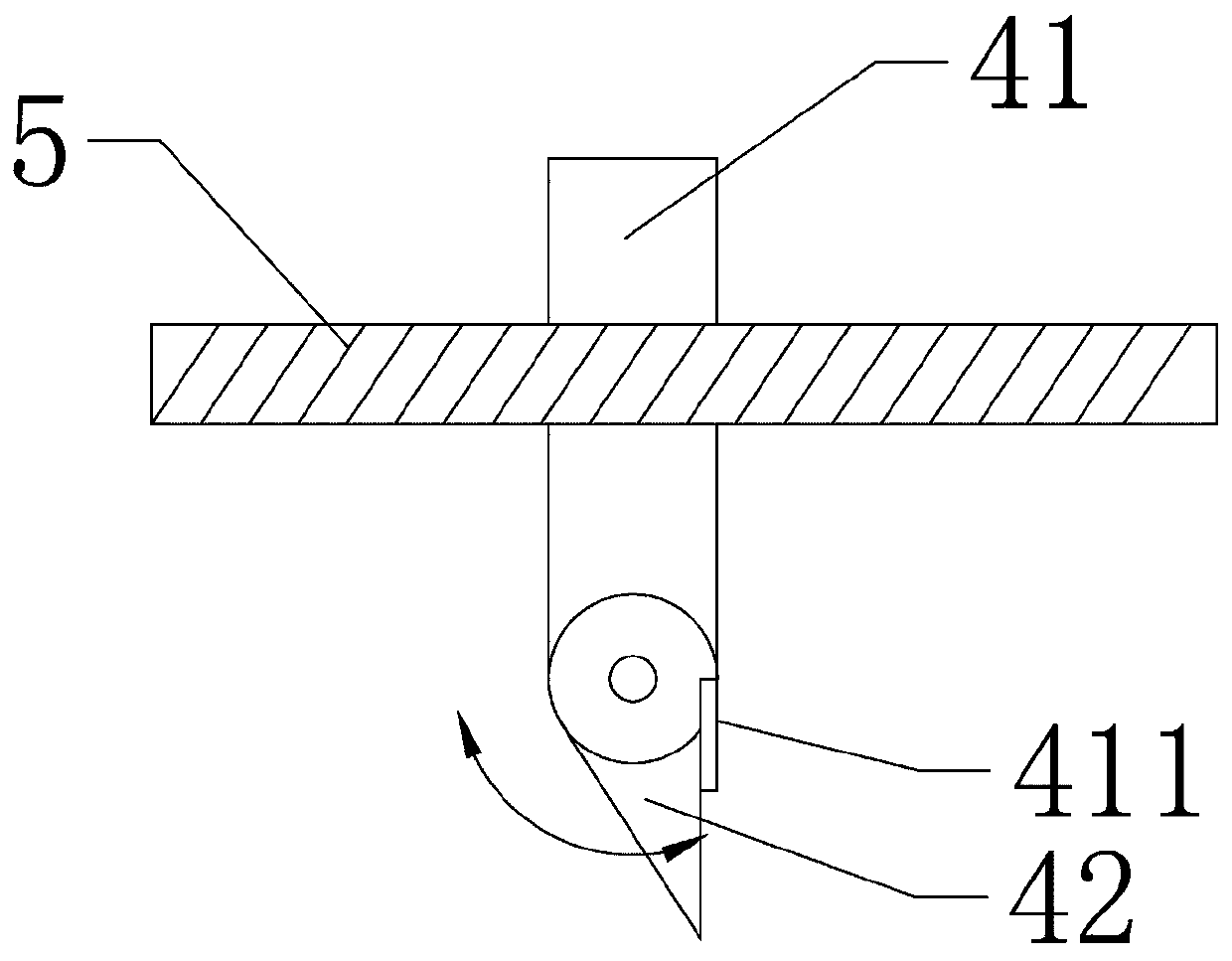

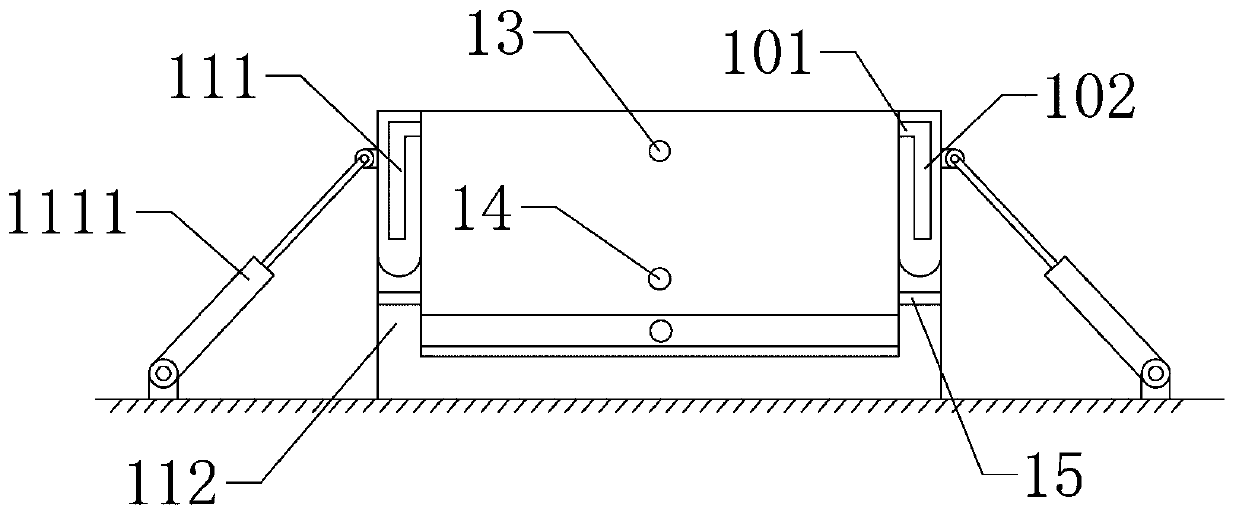

[0030] according to Figure 1 ~ Figure 3 As shown, a pickling tank for collecting sludge from steel pipes includes: pickling tank 1 and sludge collection tank 2, pickling tank 1 includes two long side walls 11 and two short side walls 12 The long side wall 11 includes an upper turning part 111 and a lower blocking part 112, the blocking part 112 is connected to the lower part of the short side wall 12 as a whole, the turning part 111 is arranged on both sides of the short side wall 12, the turning part 111 and the A sealing strip is arranged between the short side walls 12; a lifting strut 3, a sludge scraper 4 and a scraper screw 5 are arranged in the pickling tank body 1, and a lifting device 6 is arranged at both ends of the lifting strut 3, and the lifting device 6 is fixed on the top of the short side wall 12; the sludge collection tank 2 includes a lifting sealing door 21 and a screw output device 22, the lifting sealing door 21 is driven by a rack motor 23, the sludge c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com