Test board connecting device

A technology for a docking device and a test board, which is applied to the measurement device, the casing of the measurement device, and the measurement of electrical variables, etc., can solve the problems of poor docking stability, affecting work efficiency, and long time, so as to achieve good docking stability and work efficiency. High, short docking time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

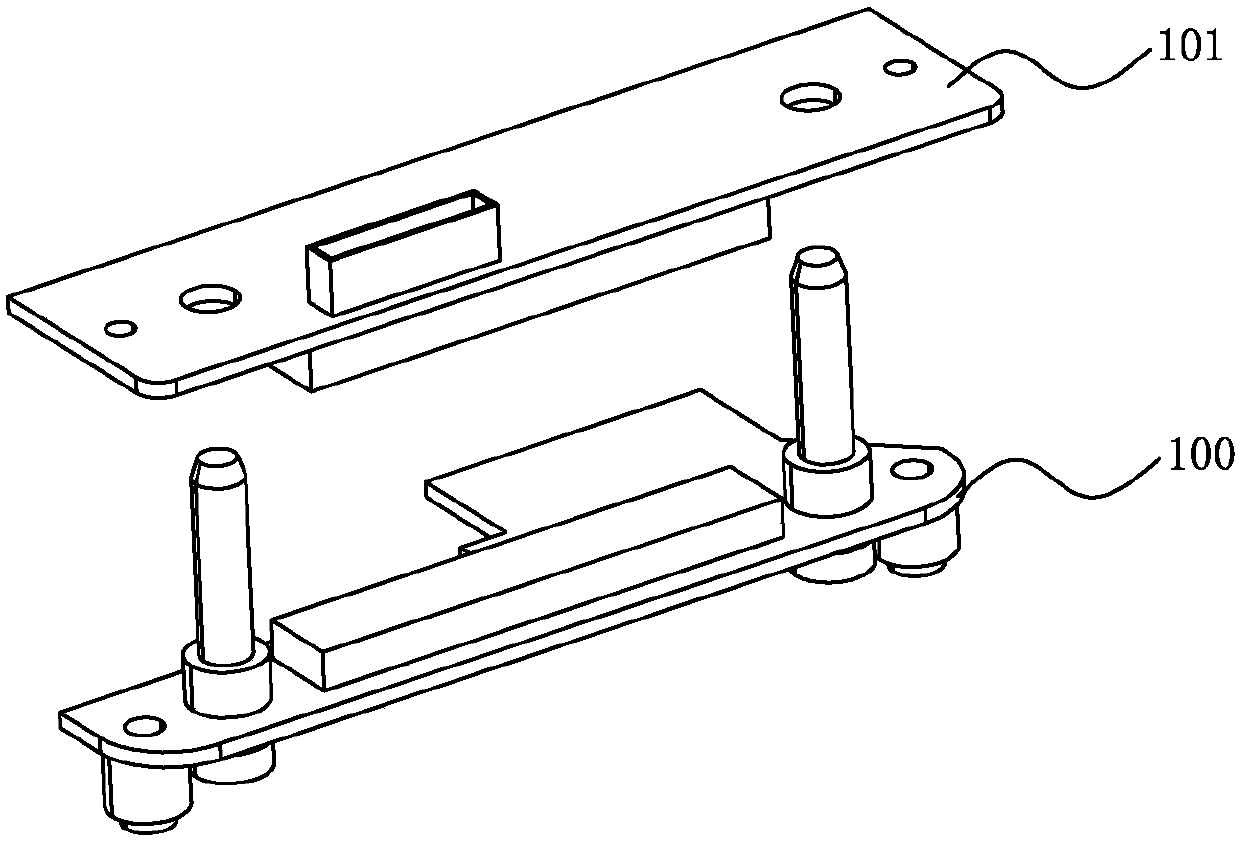

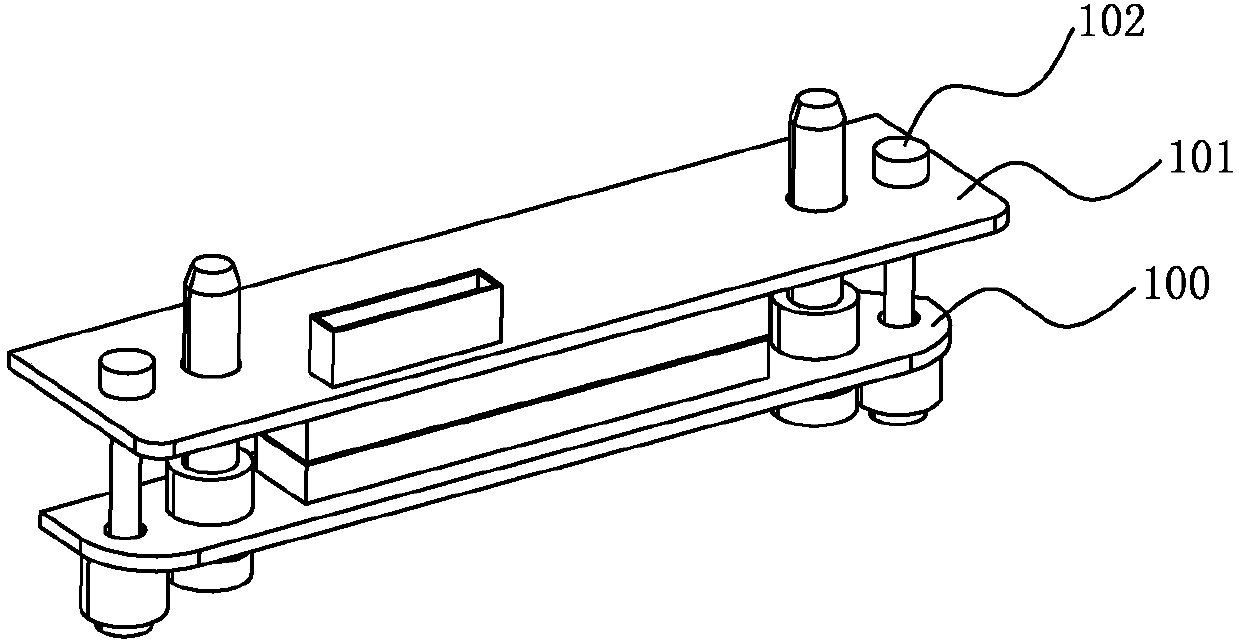

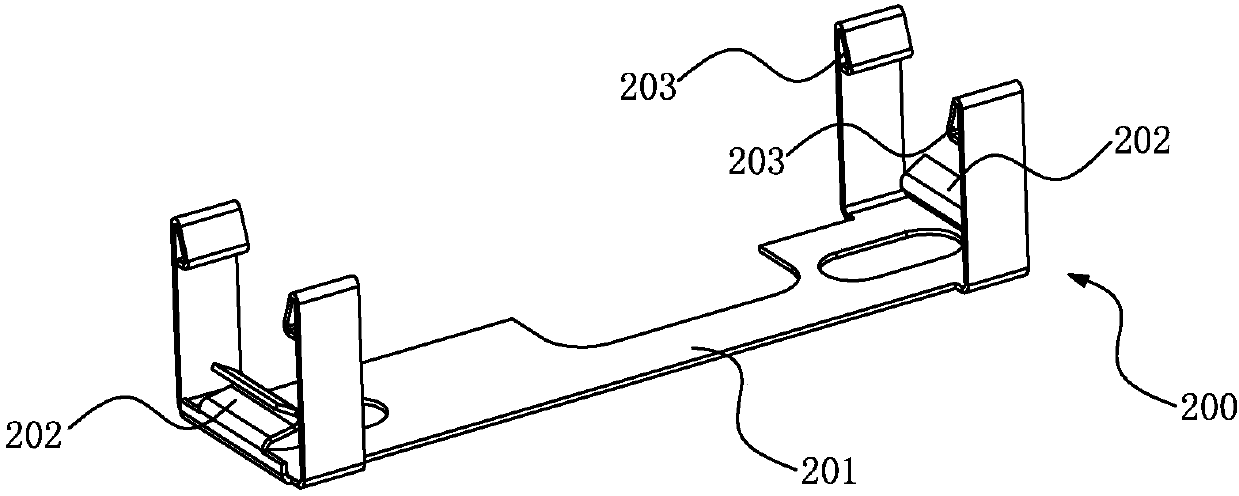

[0018] see figure 1 and image 3 shown, where image 3 A schematic diagram of the test board docking test device of the present invention is shown.

[0019] In this embodiment, the test board docking device 200 of the present invention is used for docking two test boards (100, 101). 202, the first buckle 202 clamps the two ends of one of the test boards 100, and the two sides of the bottom plate 201 extend vertically upward with the second buckle 203. After the two test boards (100, 101) are connected, the The second buckle 203 is clamped to two sides of the other test board 101 , and the elasticity of the first buckle 202 and the second buckle 203 is variable.

[0020] Wherein, the test board docking device 200 further includes a guide column 204, the guide column 204 passes through the bottom plate 201, correspondingly, the bottom plate 201 and the two test boards (100, 101) are provided with guide holes for the guide column 204 passes through, and the guide posts 204 pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com