Charging method, circuit and system of mobile power source

A mobile power supply and charging circuit technology, applied in the direction of secondary battery charging/discharging, battery disconnect circuit, battery circuit device, etc., can solve the problems of high power, no temperature control function, circuit short circuit, etc., to achieve a good user experience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

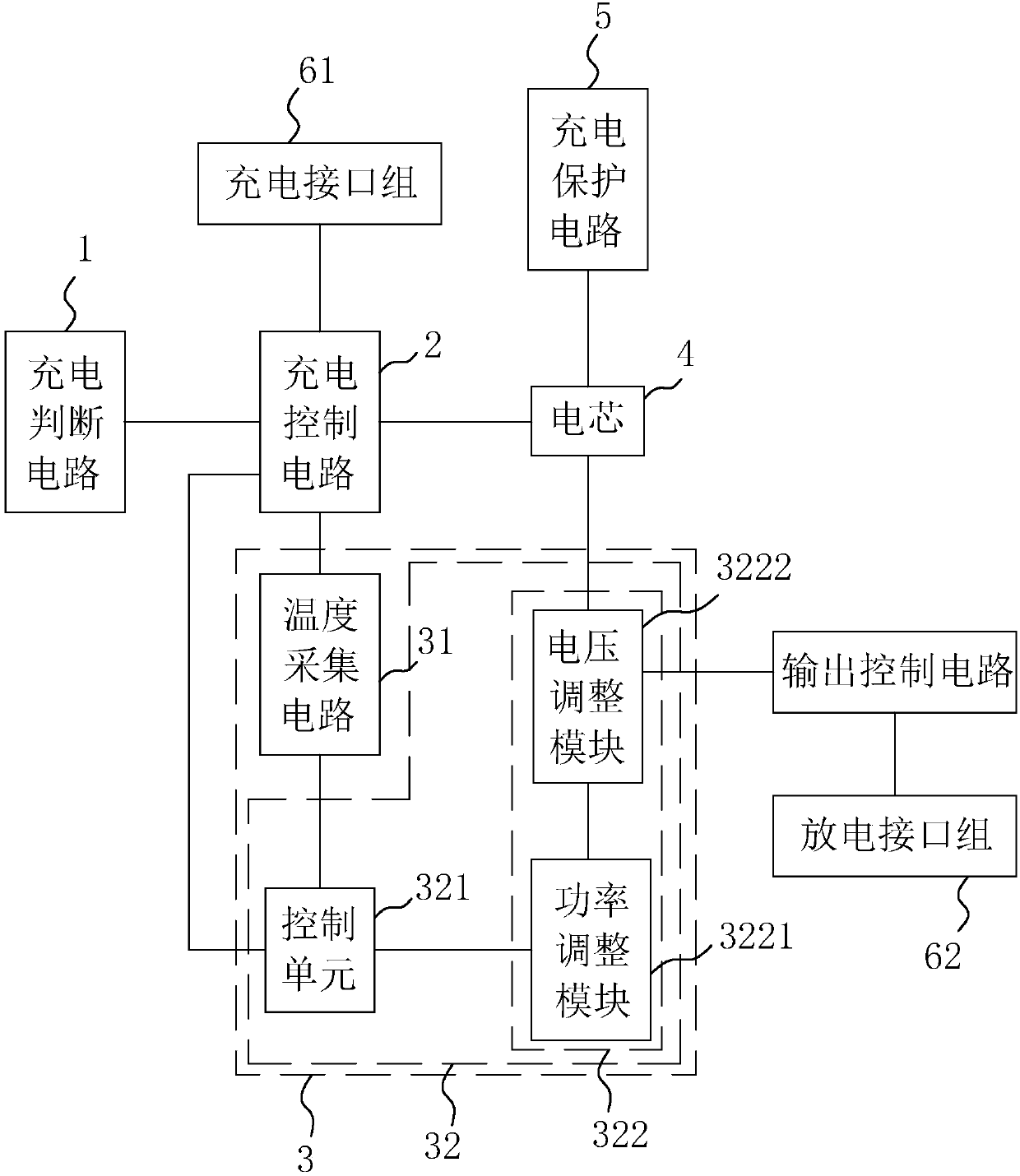

[0056] A charging system for mobile power, such as figure 1 As shown, it includes: a charging control circuit 2 connected to the battery cell 4 for controlling the charging and discharging state of the battery cell 4; a charging circuit 3 connected to the charging control circuit 2; a charging judgment circuit 1 connected to the charging control circuit 2 , for connecting the power adapter or load with the charging circuit 3; the charging protection circuit 5 connected to the battery cell 4; and the charging interface group 61 and the discharging interface group 62.

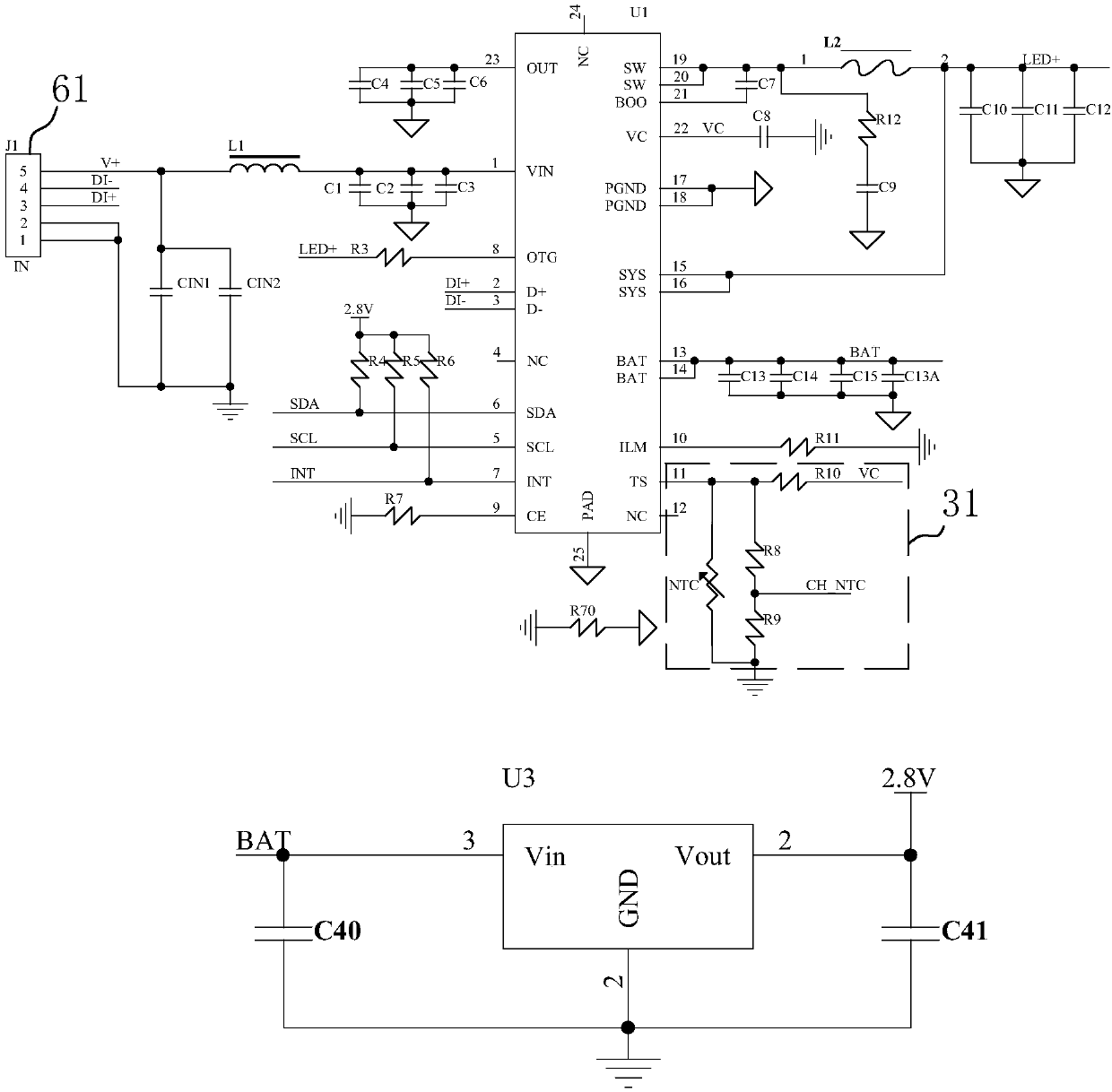

[0057] Specifically, such as figure 2 As shown, the charging control circuit 2 and the charging judging circuit 1 are mainly implemented by the control chip U1 and its peripheral circuits. The charging interface group 61 is connected to the control chip U1 for connecting to a power adapter. A common charging interface can be used, such as: USB interface, PSP interface, Type-C interface, etc., wherein the fifth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com