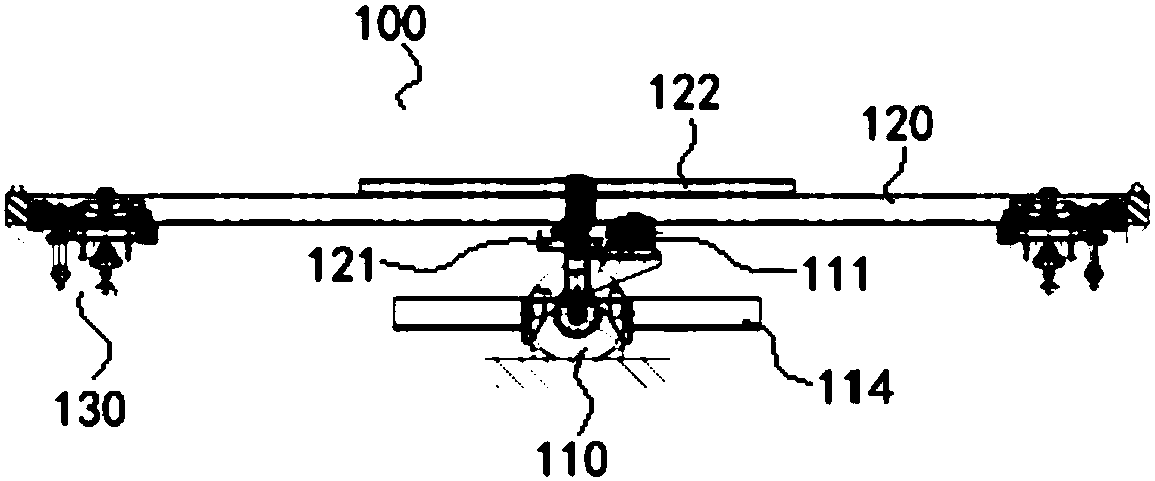

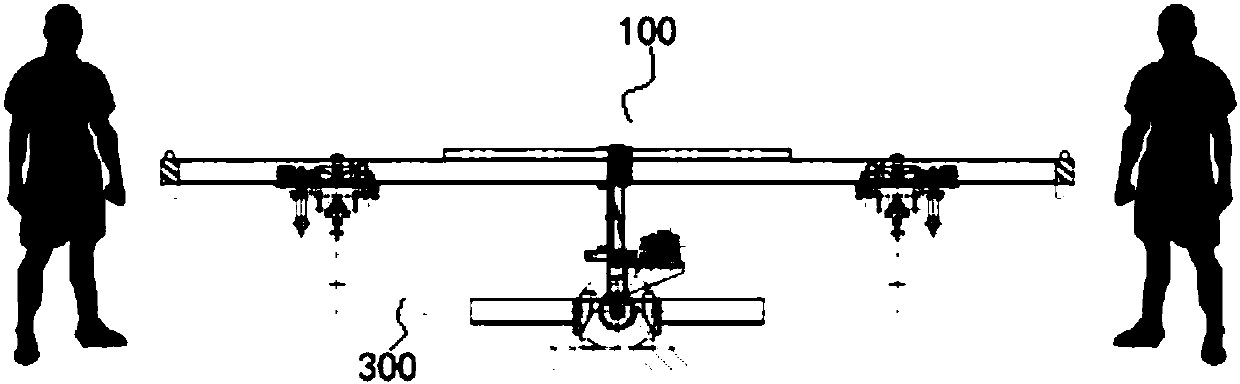

Small component moving and installing system and method

A technology for installing systems and components, which is applied to hoisting devices, portable lifting devices, etc., to achieve the effects of small size, improved installation efficiency, and improved transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

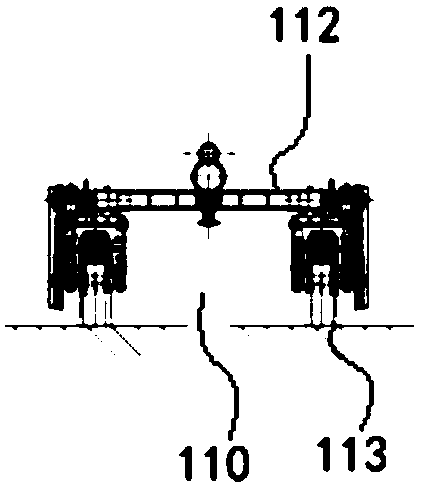

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0050] This example takes the corresponding prefabricated cover plate as an example. The size of the prefabricated cover plate is relatively small (the largest is width 490*thickness 100*length 2900).

[0051] Here, let me first introduce the prefabrication process of the prefabricated cover plate cited in this example. The whole process includes the following steps:

[0052] (1) Laying of plastic diaphragm

[0053] Before the construction of steel bars and formwork, the plastic diaphragm should be laid in advance to ensure the construction quality of the concrete and facilitate the lifting of the prefabricated slab.

[0054] When laying the plastic diaphragm, according to the actual size of each board and release 10cm more on each side for cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com