Brake cylinder clearance adjusting mechanism and brake cylinder

A gap adjustment mechanism and brake cylinder technology, applied in the direction of brake types, brake parts, axially joined brake parts, etc., can solve the problems of increasing structural complexity, thread looseness, etc., to prevent loosening and ensure clearance relief value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

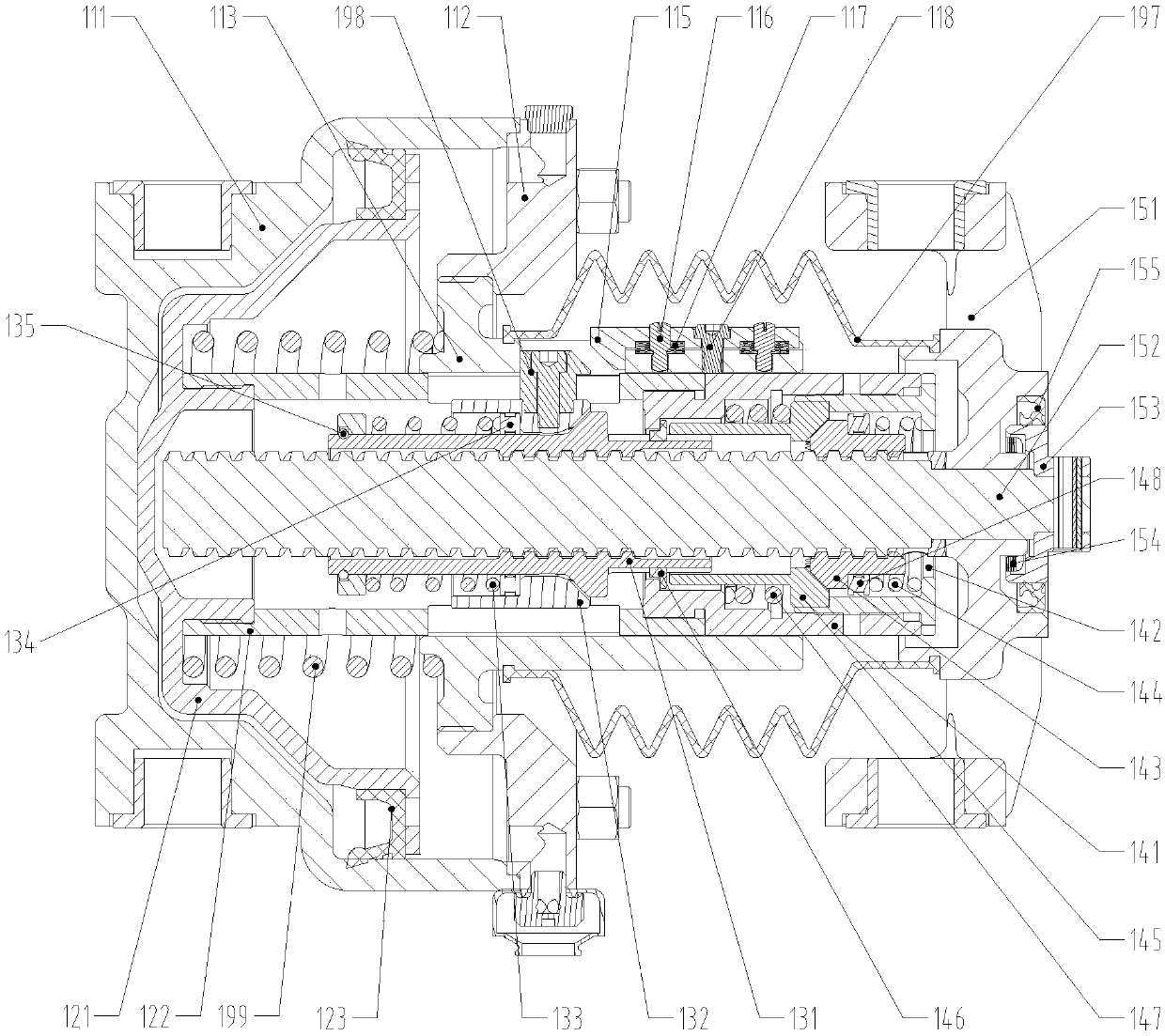

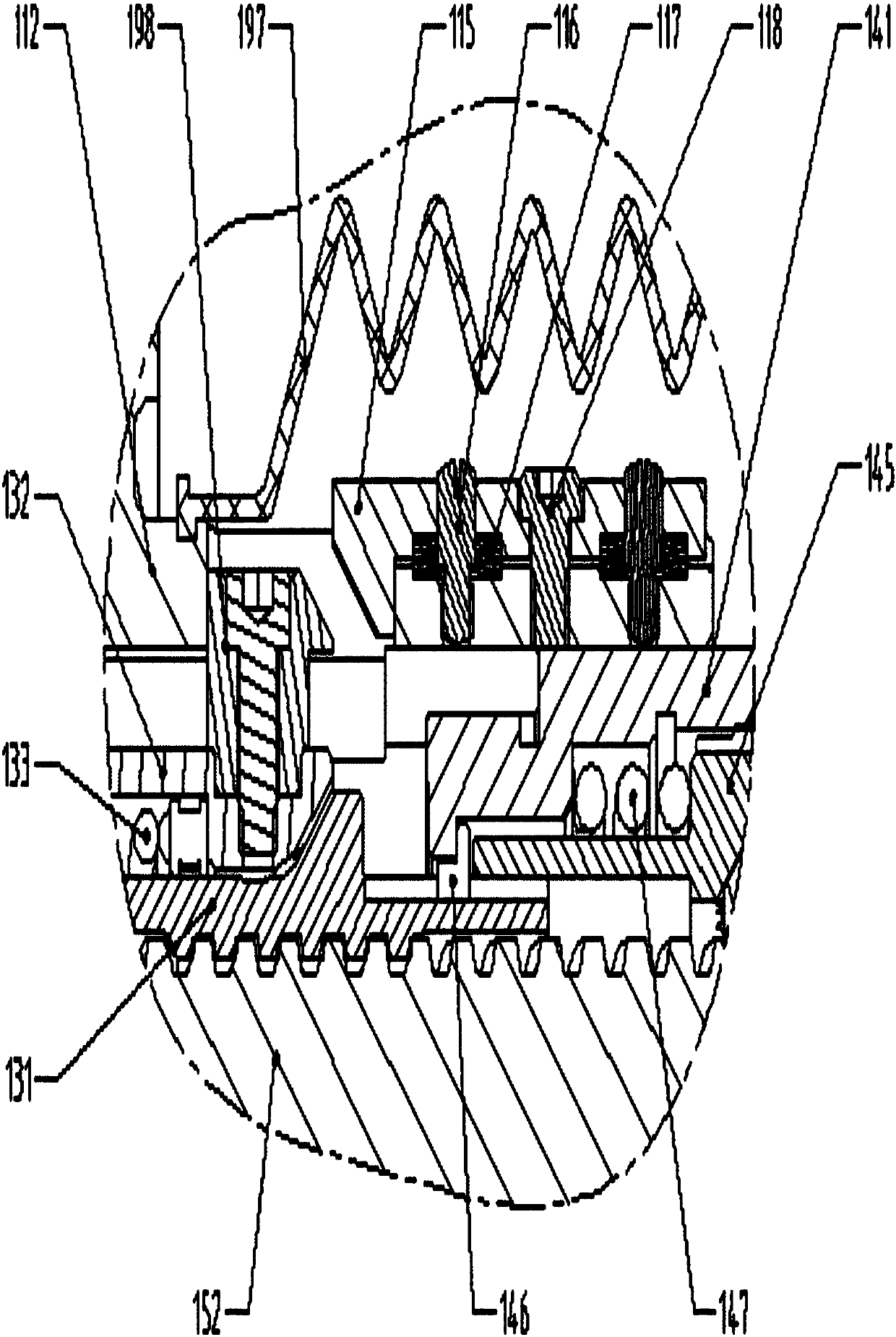

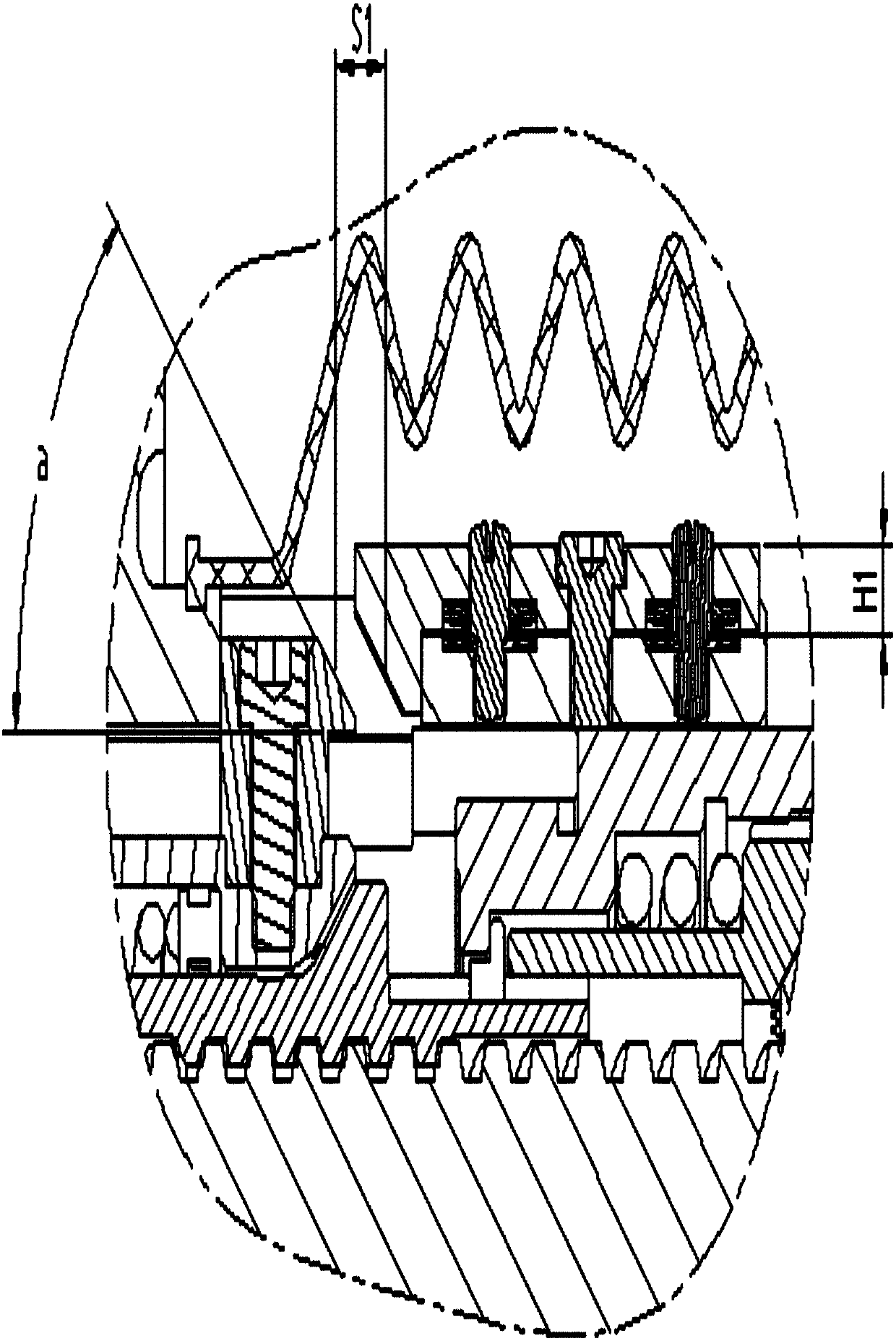

[0055] The basic structure of the brake cylinder gap adjustment mechanism in this embodiment is as follows: figure 1 and figure 2 As shown, it includes a cylinder body 111, a cylinder head 112 and a cylinder head pipe 113 that are fixedly connected to each other. The inner cavity of the cylinder head pipe 113 is nested with a piston pipe 122 that forms an axial movement pair with it. The inner end of the piston pipe 122 is located at the The piston 121 in the cylinder is fixed in the axial direction, and a relief spring 199 is installed between the cylinder head tube 113 and the piston; Have square keyway and wedge-shaped adjusting block 115 installation grooves. A taper sleeve 145 and a guide nut 143 engaged with end faces are installed inside the guide damper body 141 , and the ends of the taper sleeve 145 and the guide nut 143 away from the meshing abut against the damper spring 147 and the guide spring 144 respectively. The inner hole of the guide nut 143 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com