Light source adjustment mechanism for red dot sight

A light source adjustment and inner red dot technology, applied in the direction of aiming devices, weapon accessories, offensive equipment, etc., can solve the problems of poor precision, difficult to control, and prone to skewing, etc., and achieve simple structure, easy manufacturing and mass production, and good lighting Effect of orientation adjustment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

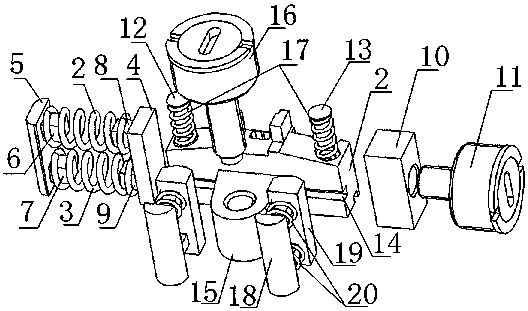

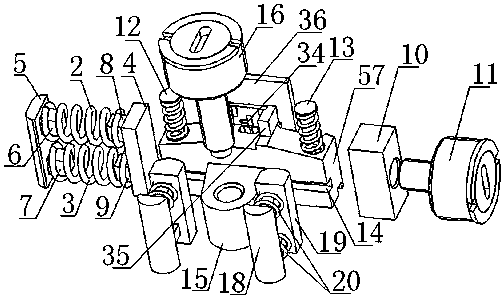

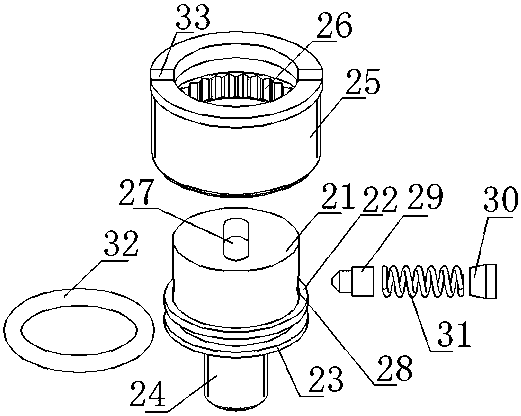

[0033] figure 1 Shown is a light source adjustment mechanism for an inner red dot sight, including an LED installation base 1, a horizontal compression spring assembly, a horizontal adjustment assembly, and a vertical adjustment assembly, as well as a stabilizing assembly placed on the rear side of the LED installation base 1.

[0034] Among them, the horizontal compression spring assembly and the horizontal adjustment assembly are relatively installed on the left and right sides of the LED installation base 1, thereby forming the position adjustment of the left and right directions of the LED installation base 1. The horizontal compression spring assembly specifically includes at least two spiral Spring 1 2, 3, left top block 4 and spring limit block 1 5, and coil spring 1 2, 3 can only be compressed or reset along the direction perpendicular to the spring limit block 1, to ensure that the LED mounting base 1 Position adjustment in the horizontal direction; the inner surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com