Charging connector appearance detection fixture

A technology for charging connectors and appearance inspection, which is applied to measuring devices, instruments, etc., can solve problems such as errors and high work intensity, and achieve the effects of preventing wear, avoiding inspection time, and improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

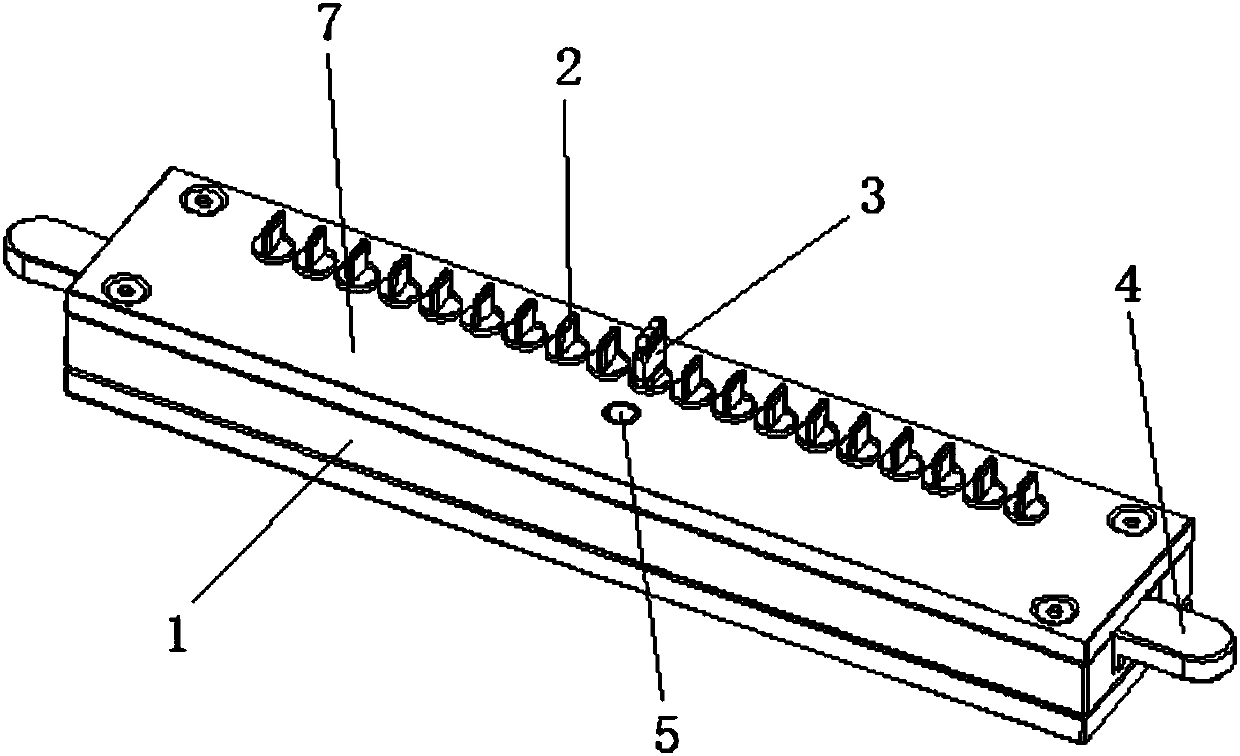

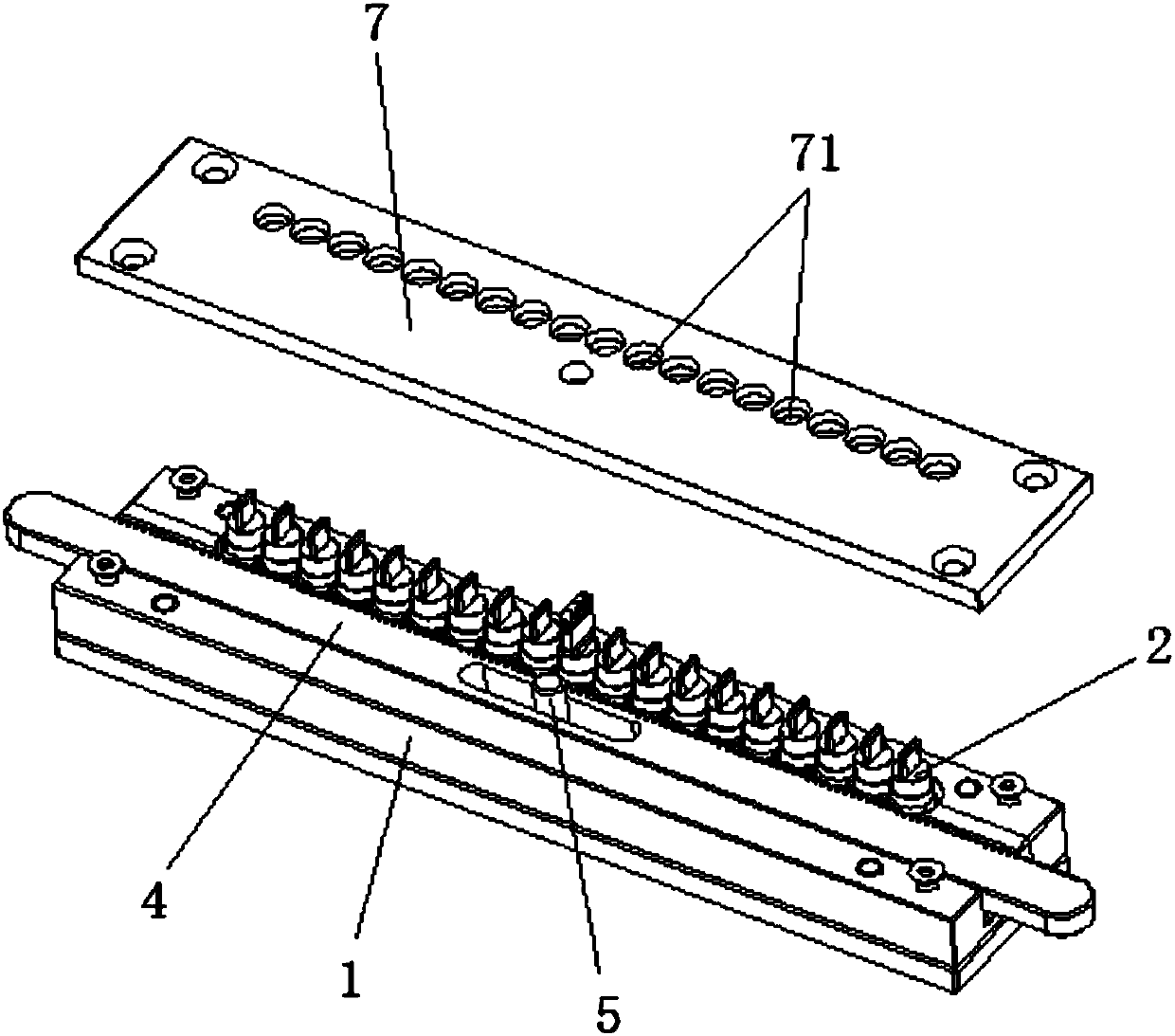

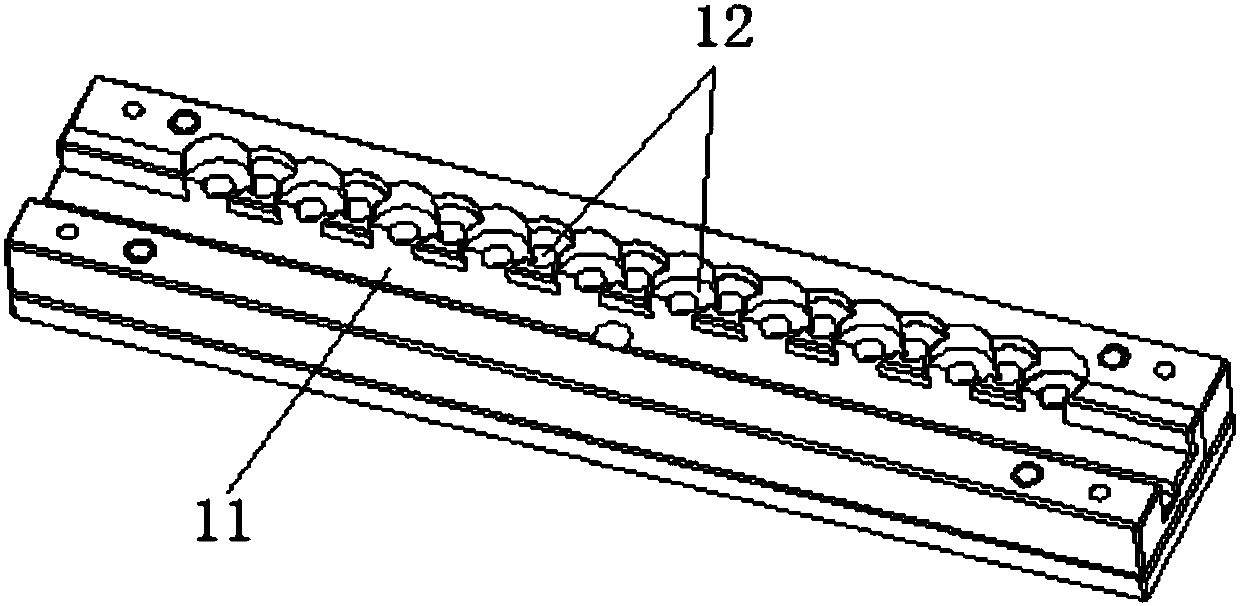

[0030] See Figure 1 to Figure 8 , the present invention includes a base 1; the base 1 is provided with a chute 11 extending along a straight line; the base 1 is provided with a plurality of installation cavities communicating with the chute 11 along the extending direction of the chute 11 12. Each installation cavity 12 is equipped with a fixing assembly 2; the fixing assembly 2 includes a shaft body 21; the shaft body 21 is rotatably arranged in the installation cavity 12, and the shaft body 21 is provided with a mounting bracket for fixing the charging connector 3 Fixing tooling 22; shaft body 21 is coaxially provided with transmission gear 23; said chute 11 is slidingly provided with drive rack 4;

[0031] The driving rack 4 is provided with a limiting long hole 41 extending along the extension direction of the driving rack 4; the base 1 is provided with a positioning pin 5; the positioning pin 5 penetrates into the limiting long hole 41 .

[0032] The transmission gears...

Embodiment 2

[0037] In the present invention, an annular chute 11 is provided on the base 1, and other technical features are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com