A mounting head and a mounting device

A technology for mounting devices and mounting heads, which is applied in the direction of electrical components, electrical components, etc., can solve the problems of increased weight of the mounting head, larger load, and slower moving speed of the mounting head, and achieve the effects of shortening the stroke and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

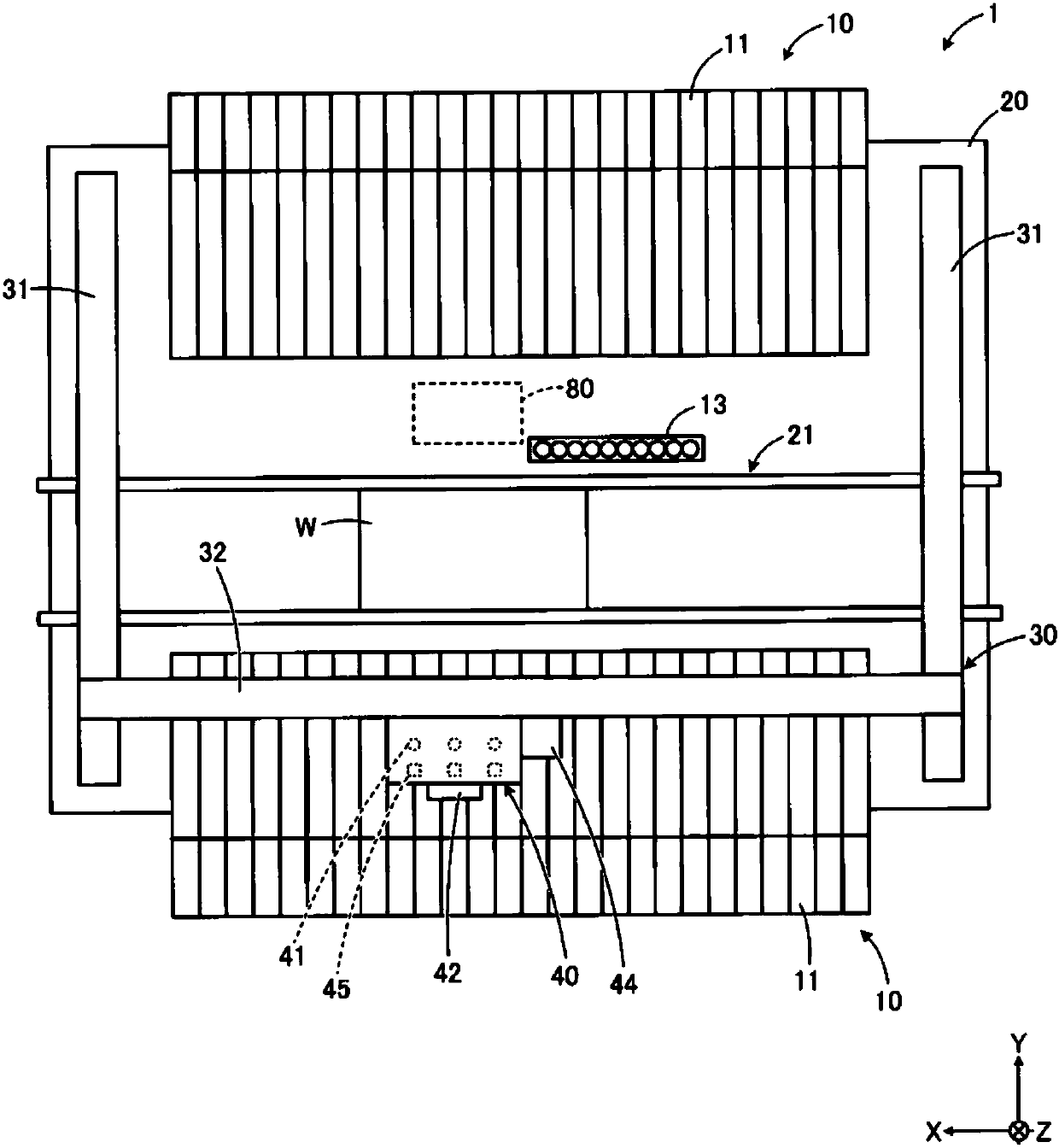

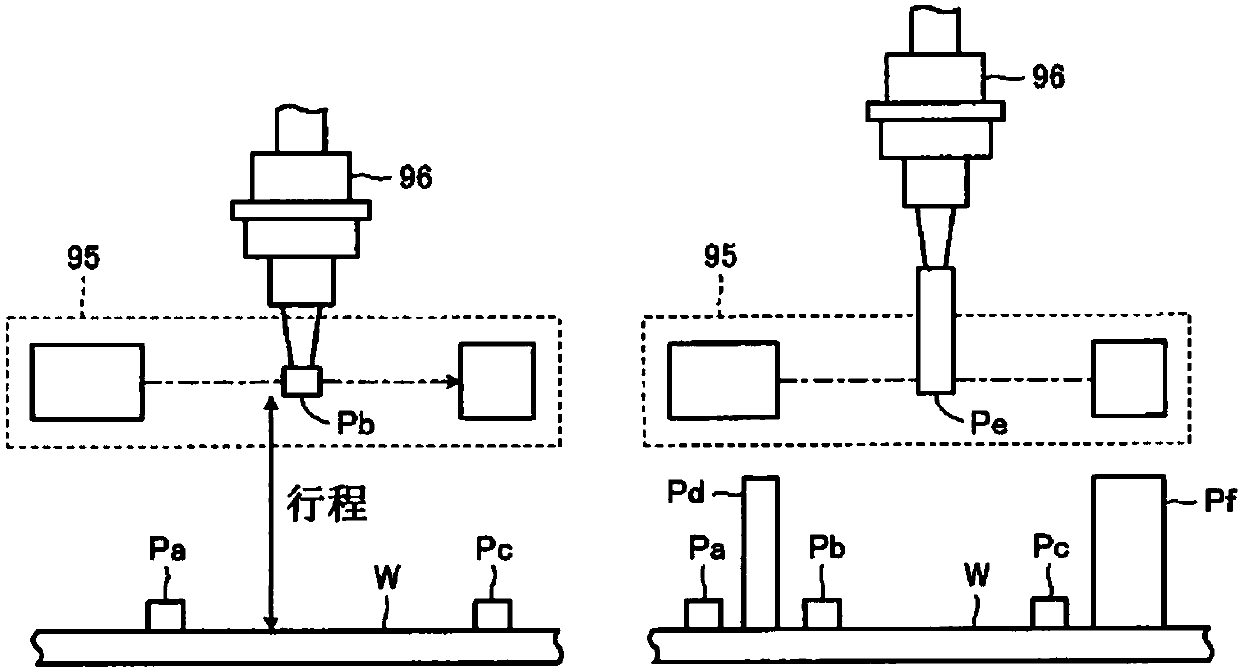

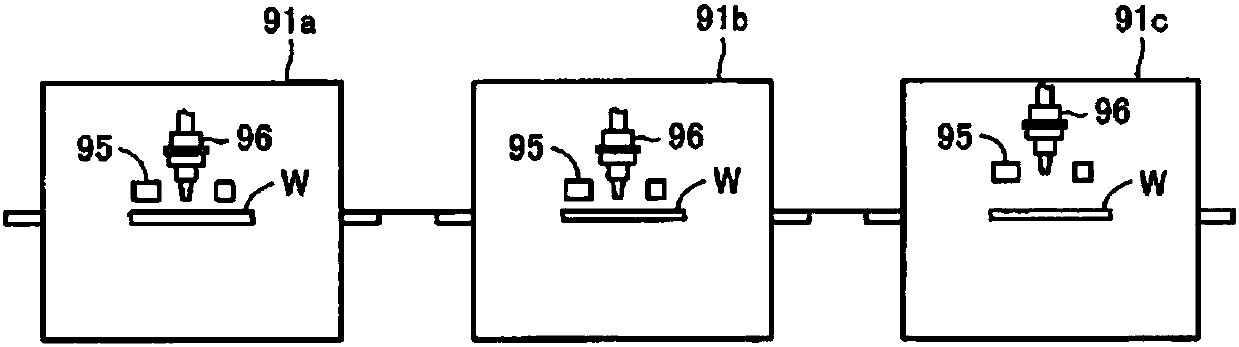

[0057] Next, a mounting device according to a first embodiment will be described with reference to the drawings. figure 1 It is a schematic diagram which shows the whole mounting apparatus of 1st Embodiment. FIG. 2 is an explanatory diagram of a mounting operation of a comparative example. In addition, the attachment device of 1st Embodiment is just an example, and can be changed suitably.

[0058] Such as figure 1 As shown, the mounting apparatus 1 is configured to mount various components supplied from the feeder 10 on predetermined positions on the substrate W via the mounting head 40 . A substrate transport unit 21 for transporting the substrate W along the X-axis direction is arranged substantially at the center of the base 20 of the mounting apparatus 1 . The substrate transfer unit 21 carries in and positions the substrate W before component mounting under the mounting head 40 from one end side in the X-axis direction, and carries out the substrate W after component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com