Press-in mechanism for dual oil seals

A technology of double oil seals and oil seals, applied in hand-held tools, manufacturing tools, etc., can solve the problems of easily crushed oil seals, elastic deformation, leakage, etc., and achieve the effect of high precision and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

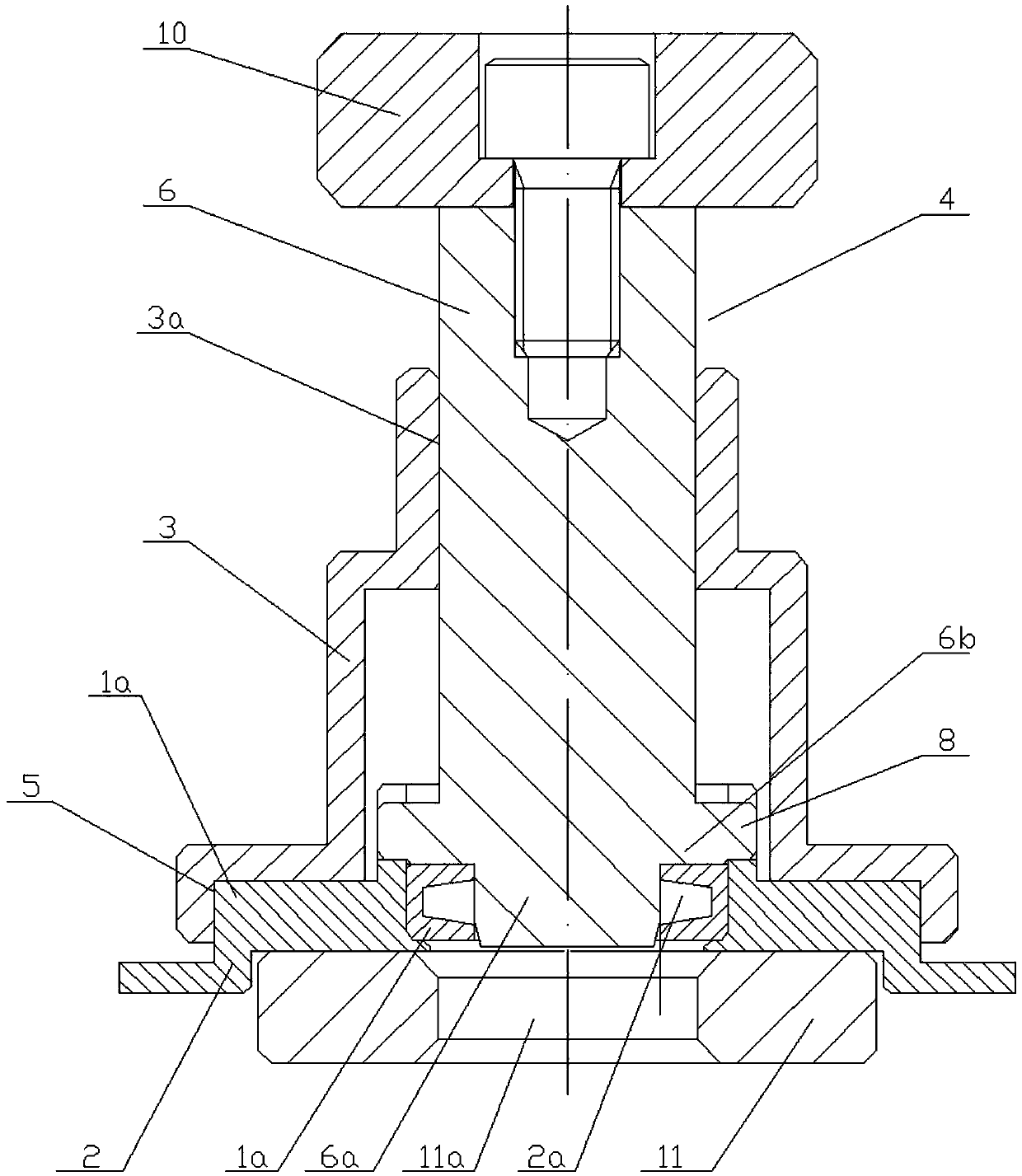

[0020] The technical solution of the present invention will be described in further non-limiting detail below in conjunction with preferred embodiments and accompanying drawings.

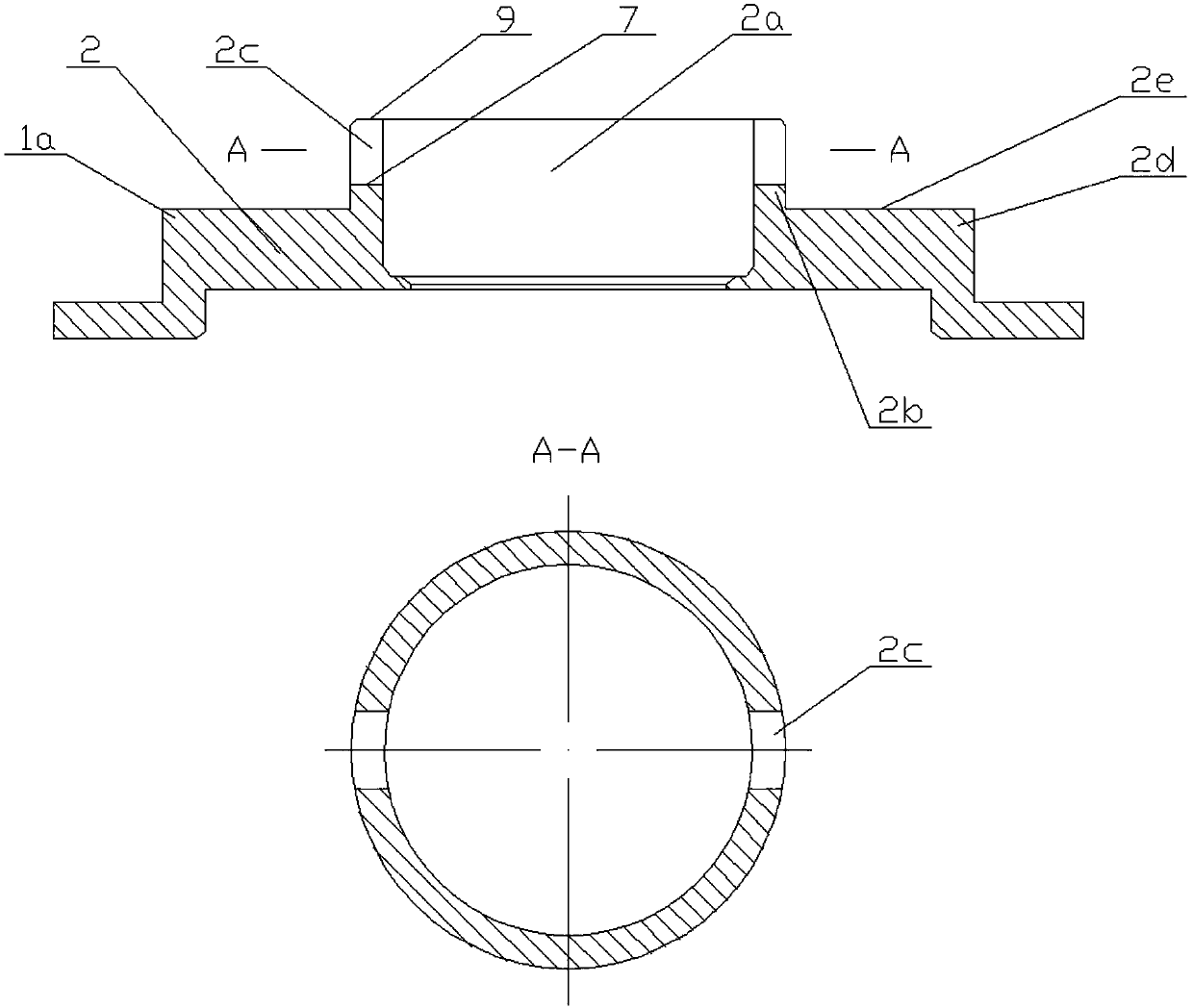

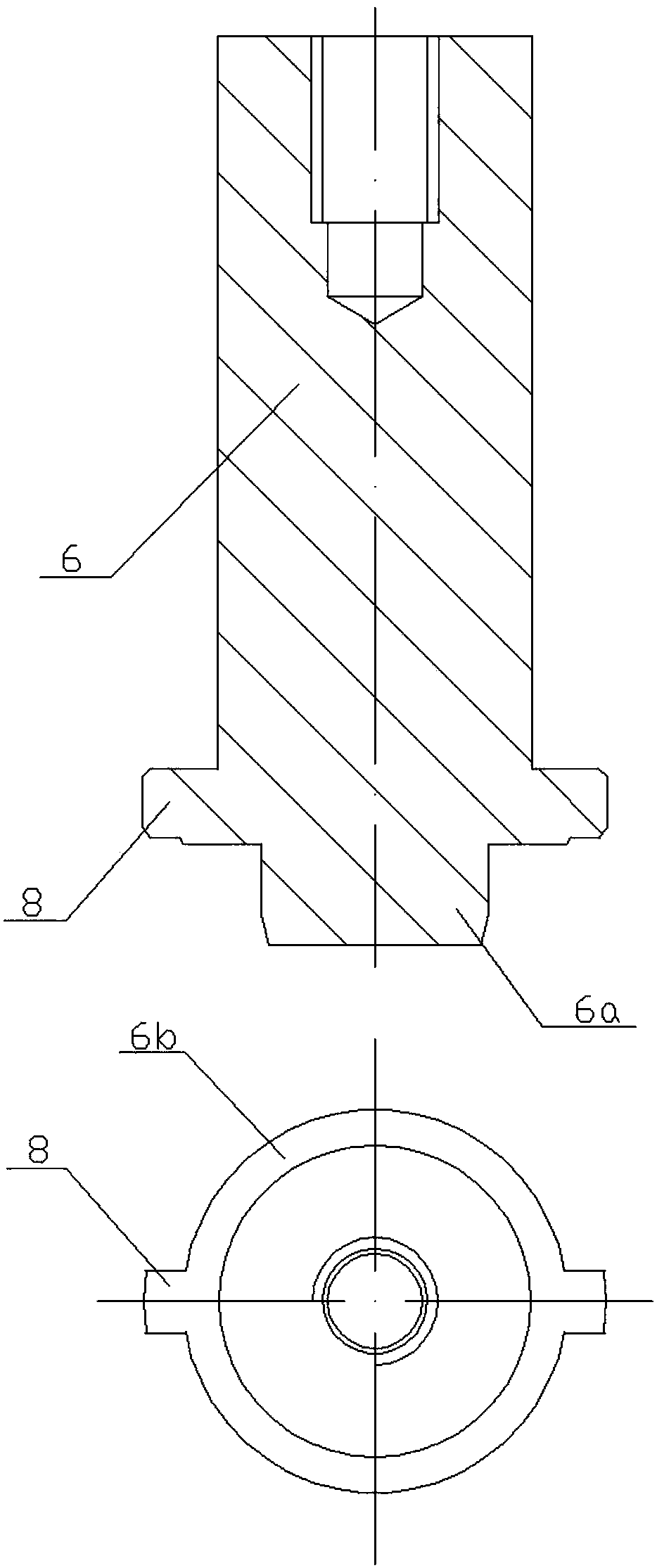

[0021] Such as Figure 1 to Figure 4 As shown, the double oil seal press-in mechanism corresponding to a preferred embodiment of the present invention is used to sequentially press the first oil seal 1a and the second oil seal 1b into the mounting hole 2a of the workpiece 2, and the end surface 2e of the workpiece 2 is set There is a convex portion 2b and a stepped portion 2d surrounding the convex portion 2b. The mounting hole 2a is opened at the center of the convex portion 2b, and the convex portion 2b is also provided with a notch 2c communicating with the mounting hole 2a.

[0022] The double oil seal press-in mechanism includes a guide sleeve 3 and an extrusion part 4 movably connected with the guide sleeve 3 .

[0023] The center of the guide sleeve 3 is provided with a guide hole 3a and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com