High-pressure hydrogenation-dehydrogenation heating reaction furnace

A high-pressure hydrogenation and reaction furnace technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of low use efficiency, low integration efficiency, secondary pollution of metal powder, etc., to ensure the use of sealing and use safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0045] It should be noted that the structures, proportions, sizes, etc. shown in this specification are only used to cooperate with the contents disclosed in the specification, so as to be understood and read by those who are familiar with this technology, and are not used to limit the conditions that the present invention can be implemented. , any modification of the structure, the change of the proportional relationship or the adjustment of the size, without affecting the effect that the present invention can produce and the purpose that can be achieved, should still fall within the scope that the technical content disclosed in the present invention can cover .

[0046] At the same time, the terms such as "up", "down", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and clarity, and are not used to limit this specification. The implementable scope of the invention, and the change or adjustment of the relative relat...

Embodiment 1

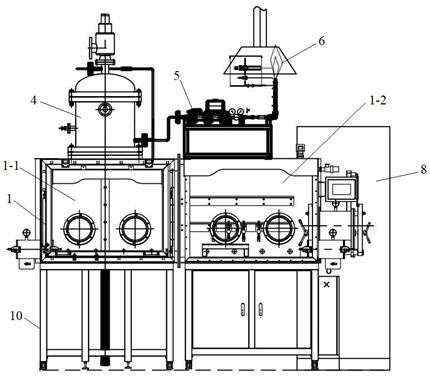

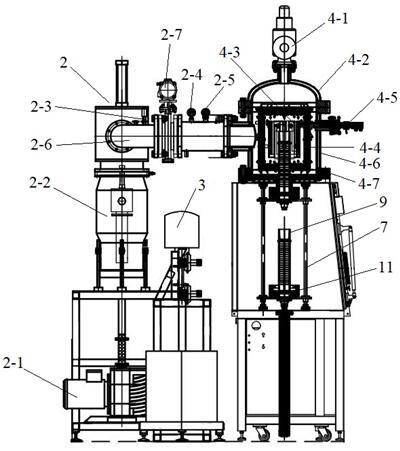

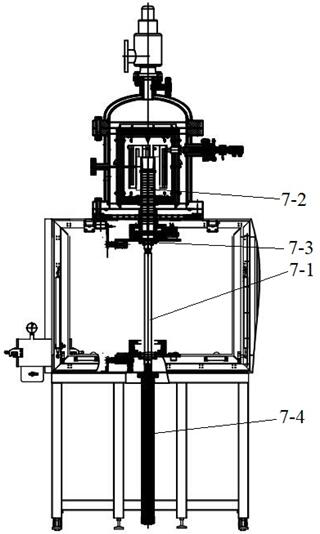

[0050] like Figures 1~3 As shown in the figure, the present invention discloses a high-pressure hydrogenation-dehydrogenation heating reaction furnace, which includes a dual-station operation glove box 1, a vacuum assembly 2, an inflatable assembly 3, a reaction assembly 4, an exhaust assembly 5, an ignition assembly 6, and a lifting assembly. 7 and the electrical control cabinet 8, the reaction assembly 4 is fixed on the top of the double-station operation glove box 1, and the bottom of the reaction assembly 4 is connected to the top of the double-station operation glove box 1, and the vacuum assembly 2 and the inflatable assembly 3 are provided On one side of the reaction assembly 4, and the vacuum assembly 2 and the gas-filled assembly 3 are respectively communicated with the reaction assembly 4, the reaction assembly 4 is connected to the exhaust assembly 5, the exhaust assembly 5 is connected to the ignition assembly 6, and the lift assembly 7 is arranged in the double. ...

Embodiment 2

[0053] like figure 1 As shown, preferably, the double-station operation glove box 1 is installed on the top of the operation bracket 10, and the double-station operation glove box 1 includes a transition compartment 1-1 and an operation compartment 1-2, and the transition compartment 1-1 is far away from One side of the operation chamber 1-2 is provided with a chamber door, and the top of the operation chamber 1-2 is fixedly connected and communicated with the reaction assembly 4 .

[0054] The reaction assembly 4 is placed on the top of the dual-station operation glove box 1 , and flanges are sealed and connected with the dual-station operation glove box 1 , and the flange is fixed with bolts to form a sealed cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com