A Coke Quenching Equipment and Process with Controllable Thin Layer Turning to the Bottom

A thin-layer, coke-quenching technology, applied in coke ovens, petroleum industry, coke cooling, etc., can solve the problems of poor effect, low cooling speed, high energy consumption, etc., to avoid excessive temperature, avoid spontaneous combustion, and prevent rotation resistance small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] Before the test starts, the temperature of the semi-coke at the outlet is designed to be 75-124° C., and the water content is 6-12% by weight.

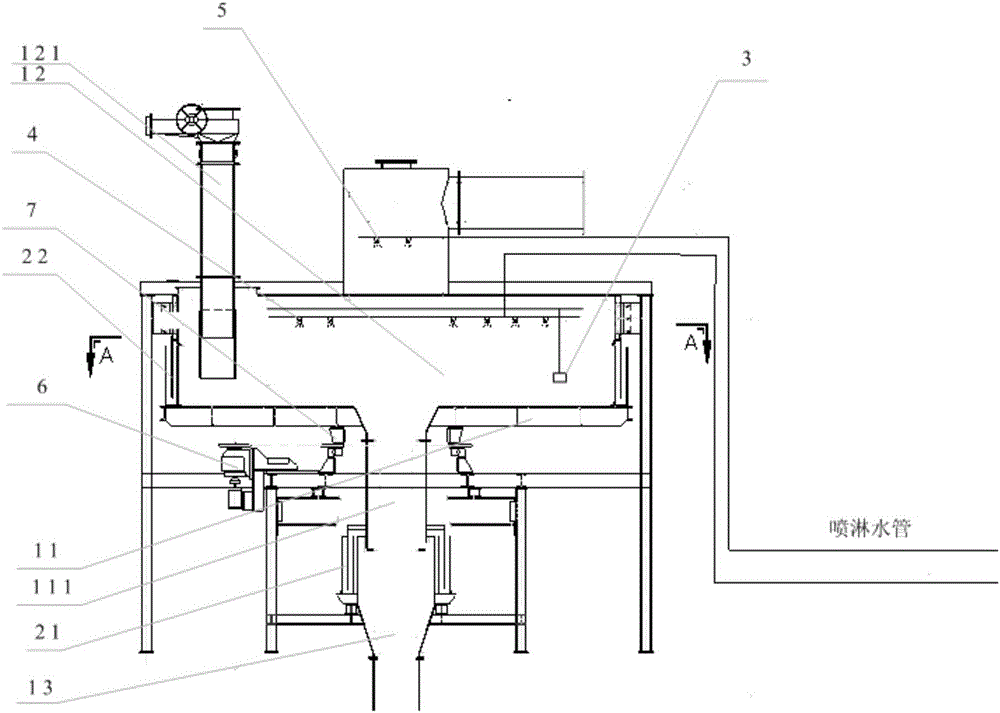

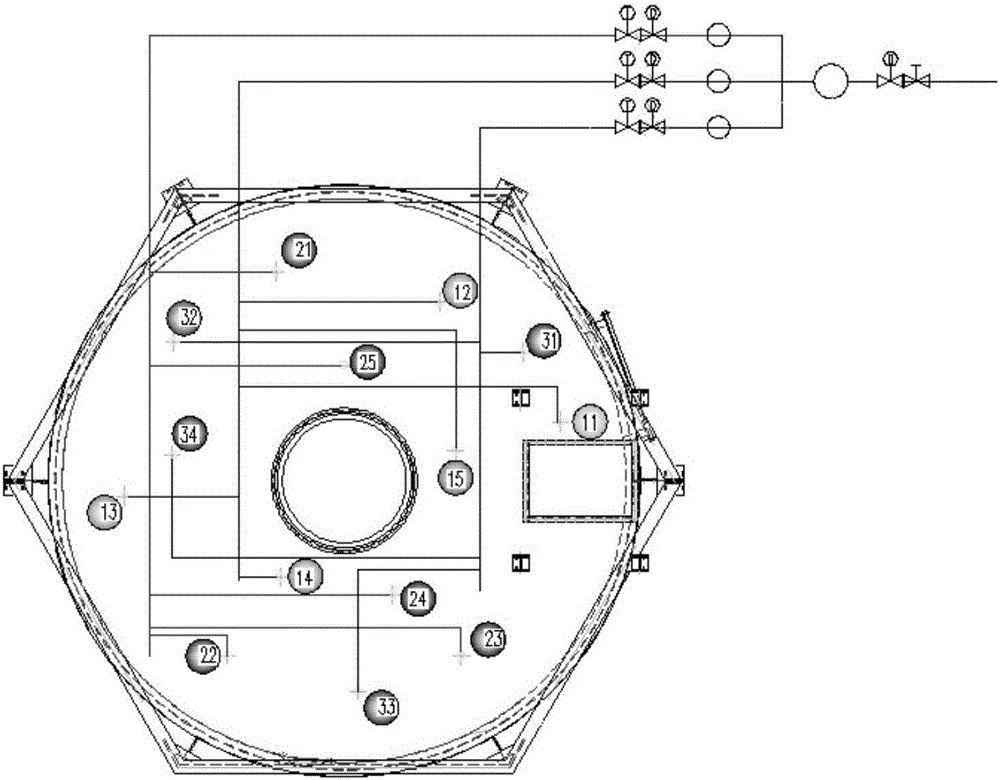

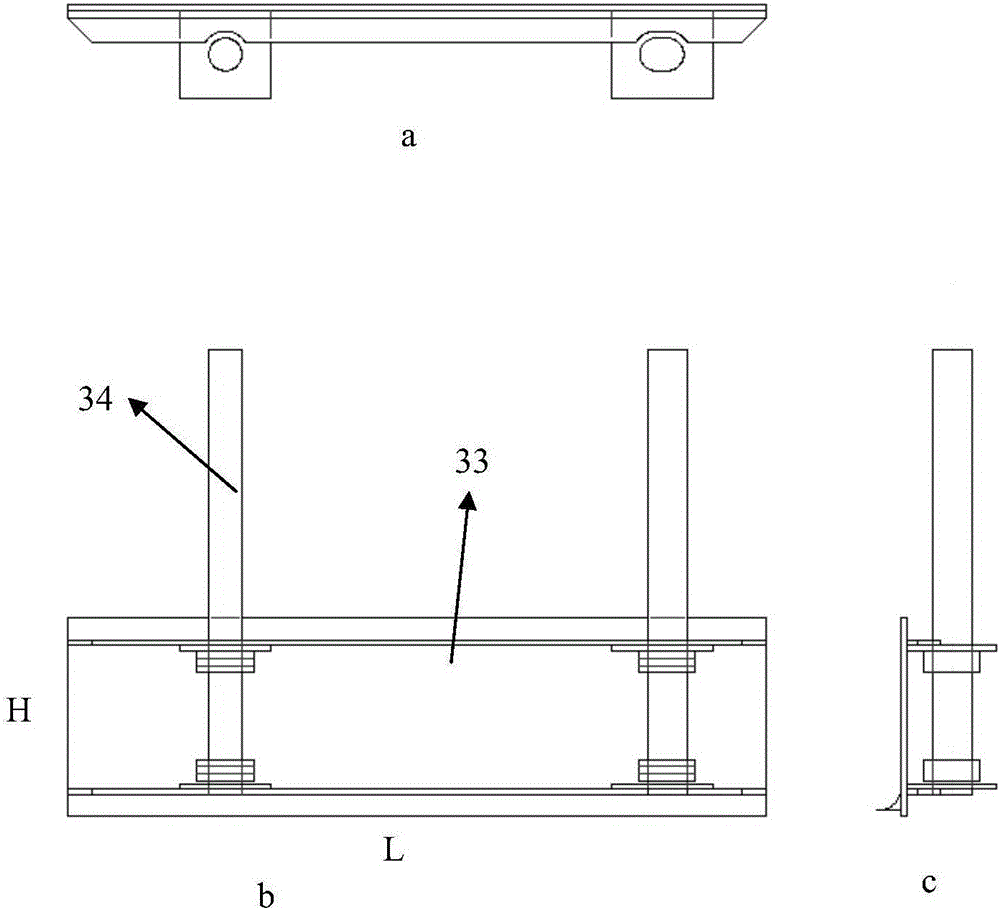

[0100] The radius of the roof of the rotary hearth furnace is 3.2m, and the maximum processing capacity of semi-coke is 20t / h. The lower edge of the deflector panel of the directional deflector and the flip deflector is equipped with an arc structure that bends toward the discharge port in the center of the turntable.

[0101] Water is injected into the first water seal tank and the second water seal tank, so that the rotary hearth furnace body is in a sealed state, and the rotary hearth furnace is started to rotate. The semi-coke obtained after the pyrolysis of lignite at a temperature of 550°C is fed to the rotary chassis at the bottom of the rotary hearth furnace of the coke quenching equipment of the present invention at a rate of 333Kg / min, and the semi-coke is cooled by the cooling water sprayed from the atomizing nozzle....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com