Plastic combined type plastic floor

A plastic floor and combined technology, applied in the floor field, can solve the problems of poor anti-slip effect, inconvenient installation, poor energy saving and environmental protection effect, etc., and achieve the effects of convenient installation, improved anti-slip effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

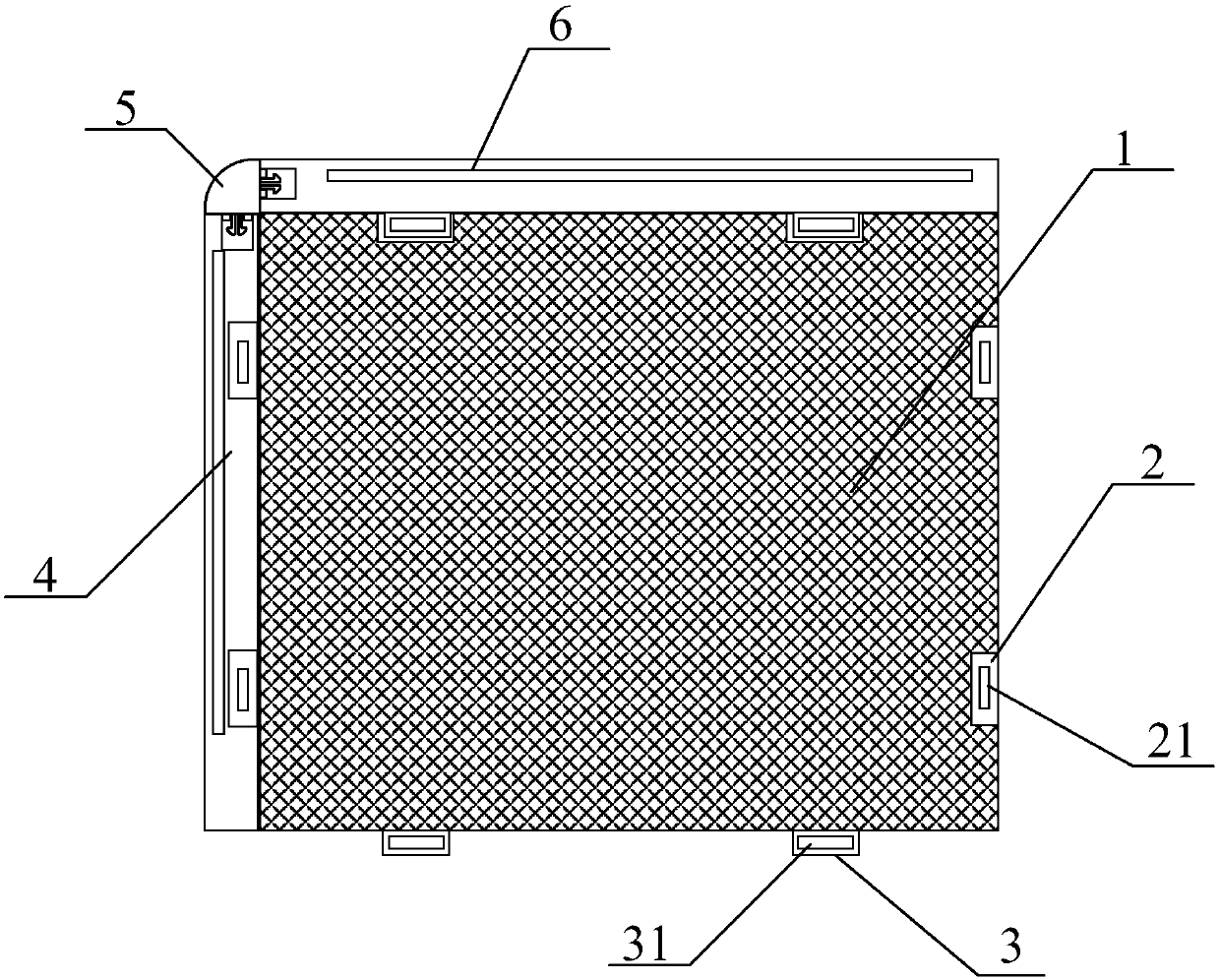

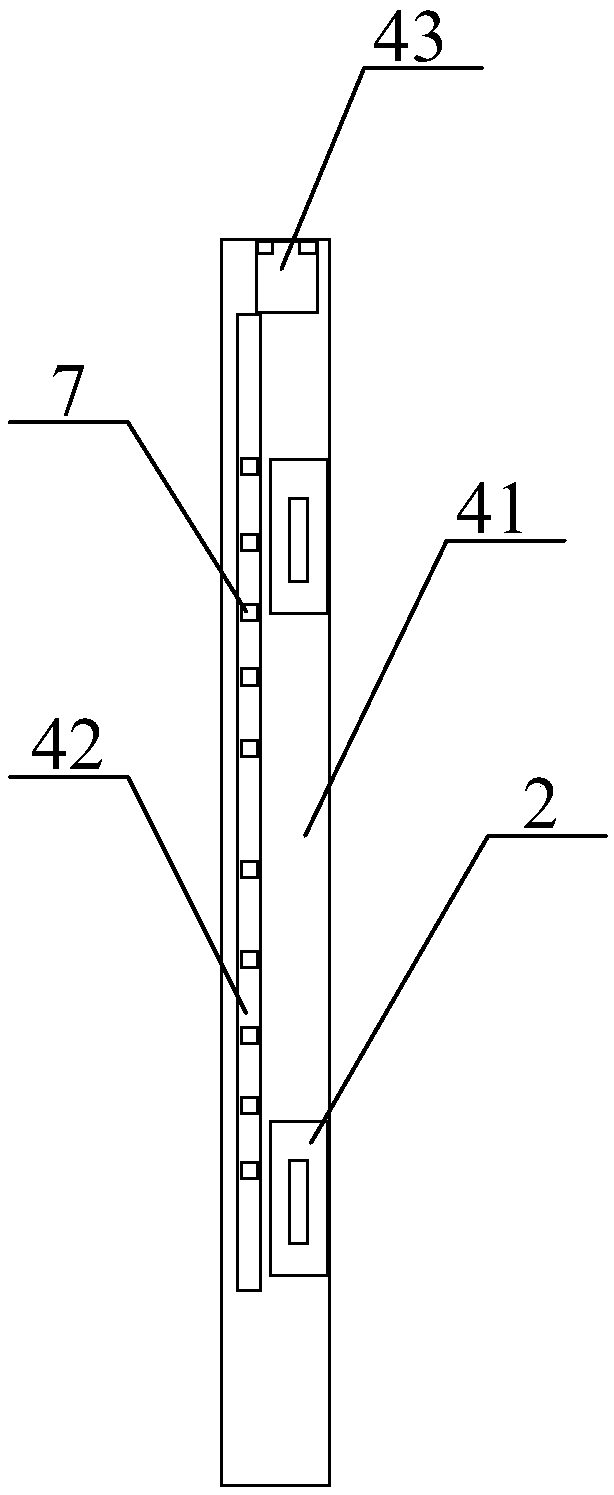

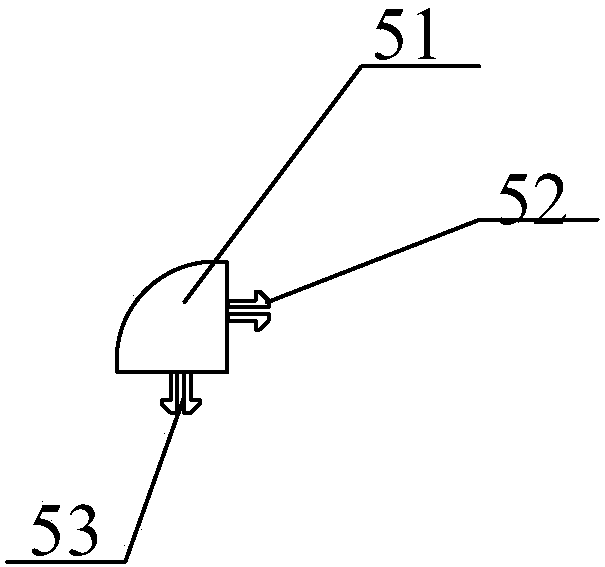

[0023] Such as Figure 1 to Figure 4 shown

[0024] The technical solution adopted by the present invention to solve the technical problems in the known technology is: a plastic combined plastic floor, including a floor 1, a connecting groove 2, a connecting block 3, a longitudinal protective edge 4, a block structure 5 and a transverse protective side 6, the connecting groove 2 is respectively arranged on the upper part, the right side and the longitudinal protective edge 4 of the floor 1; the described connecting block 3 is respectively arranged on the left side, the lower part of the floor 1 and the transverse protective edge 6; The block structure 5 described above is clamped at the junction of the longitudinal protective edge 4 and the transverse protective edge 6; the longitudinal protective edge 4 includes a longitudinal connecting edge 41, a longitudinal mounting strip 42 and a longitudinal locking groove 43, and the longitudinal locking The slot 43 is set on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com