Cigarette carton packaging method using non-woven fabric

A packaging method and technology of non-woven fabrics, applied in the field of cigarette packaging using non-woven fabrics, can solve the problems of difficulty in transportation and distribution, poor compactness of cigarette packaging, etc., achieve energy-saving and environmental protection effects, high firmness, avoid The chaotic effect of smoke piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

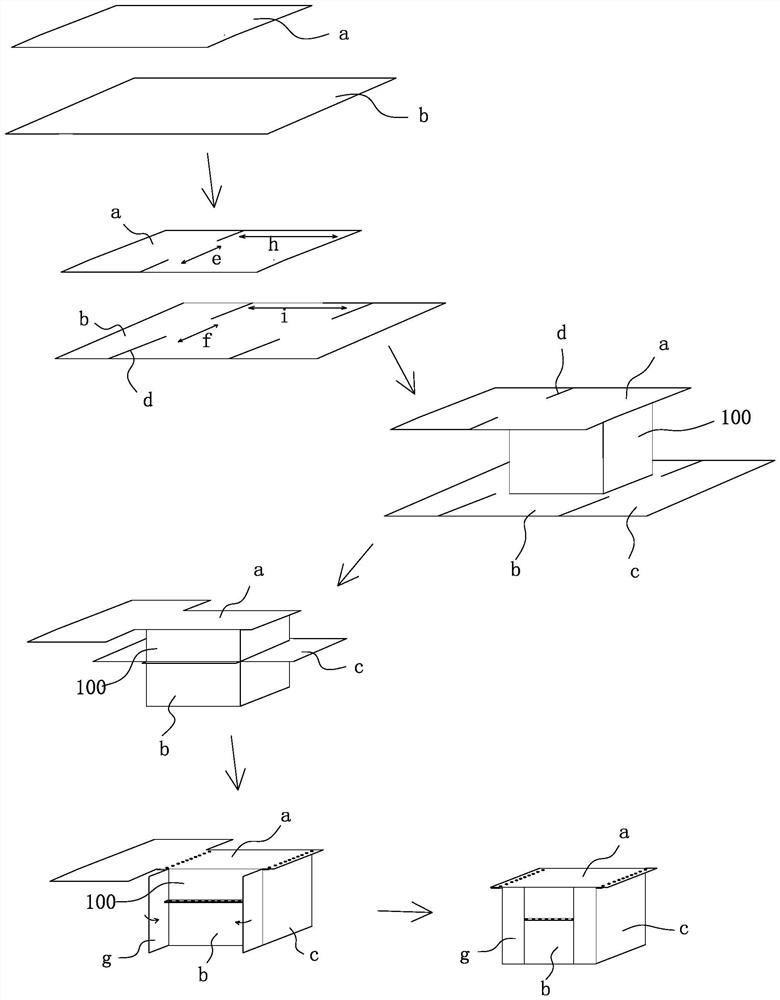

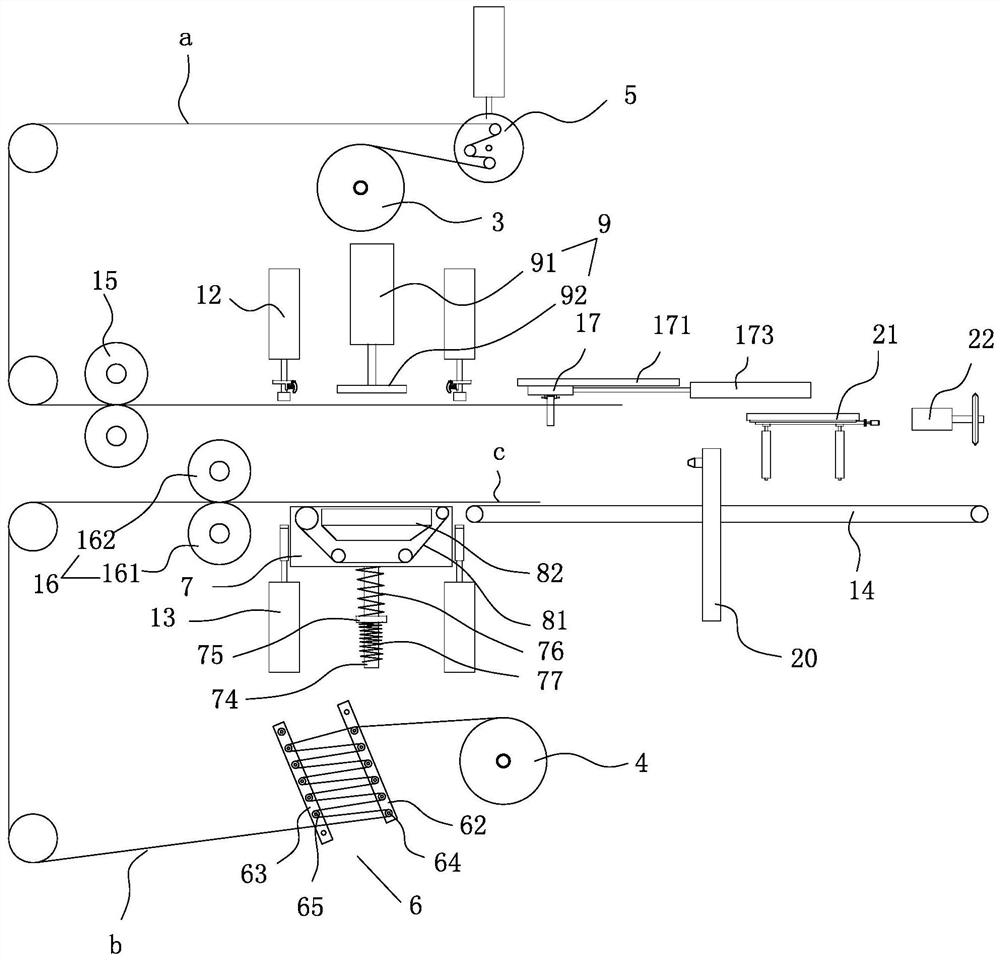

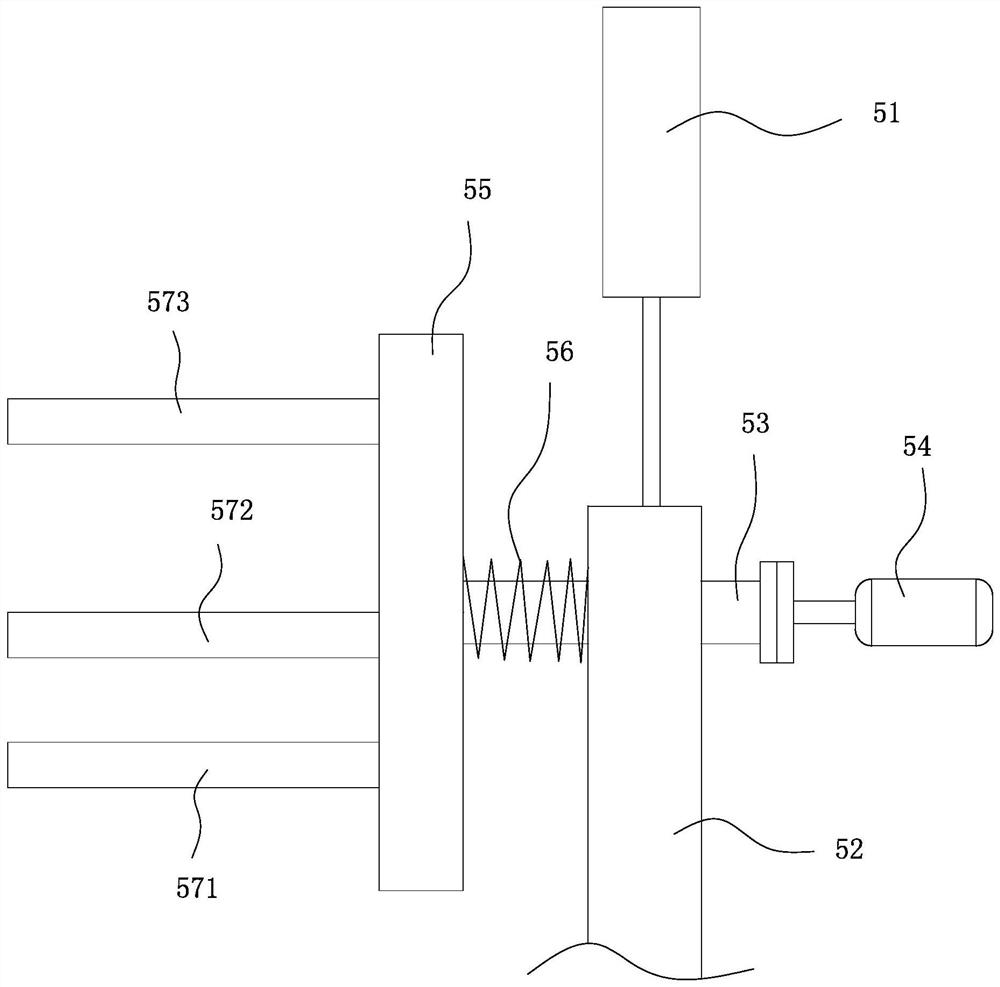

[0039] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

[0040] The embodiment of the present invention is:

[0041] refer to Figure 2 to Figure 12As shown, a cigarette packaging production line using non-woven fabrics includes a frame, a control system 2 arranged on the frame, an upper-layer non-woven unwinding assembly 3, a lower-layer non-woven unwinding assembly 4, and a tensioning assembly 5. Buffer assembly 6, worktable 7, adsorption conveying assembly 8, pressing assembly 9, first welding assembly 10, first top plate assembly 11, second welding assembly 12, second top plate assembly 13, output conveyor belt 14, upper The cutting assembly 15 , the lower cutting assembly 16 , the clamping assembly 17 , the cigarette input conveyor belt 18 , the pushing assembly 19 , the glue spraying assembly 20 , the pressing assembly 21 and the slitting assembly 22 , the tensioning assembly 5 is provided with A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com