Flange packaging structure provided with electric heating pipes

A technology of packaging structure and electric heating tube, applied in the direction of ohmic resistance heating parts, heating elements, etc., can solve the problems of affecting the firmness of the connection, easy to rust, easy to rust and loosen the nut, etc., to achieve good sealing, not easy to Rust, good firmness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described and illustrated through specific examples below.

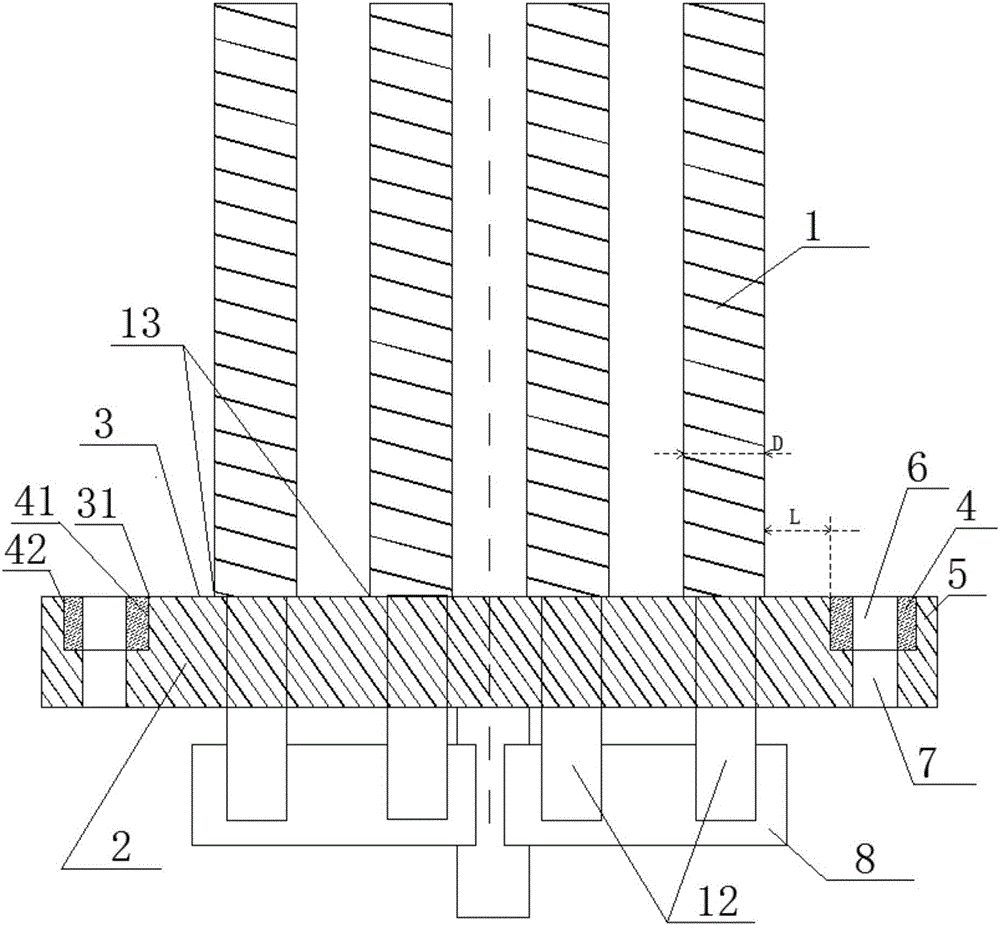

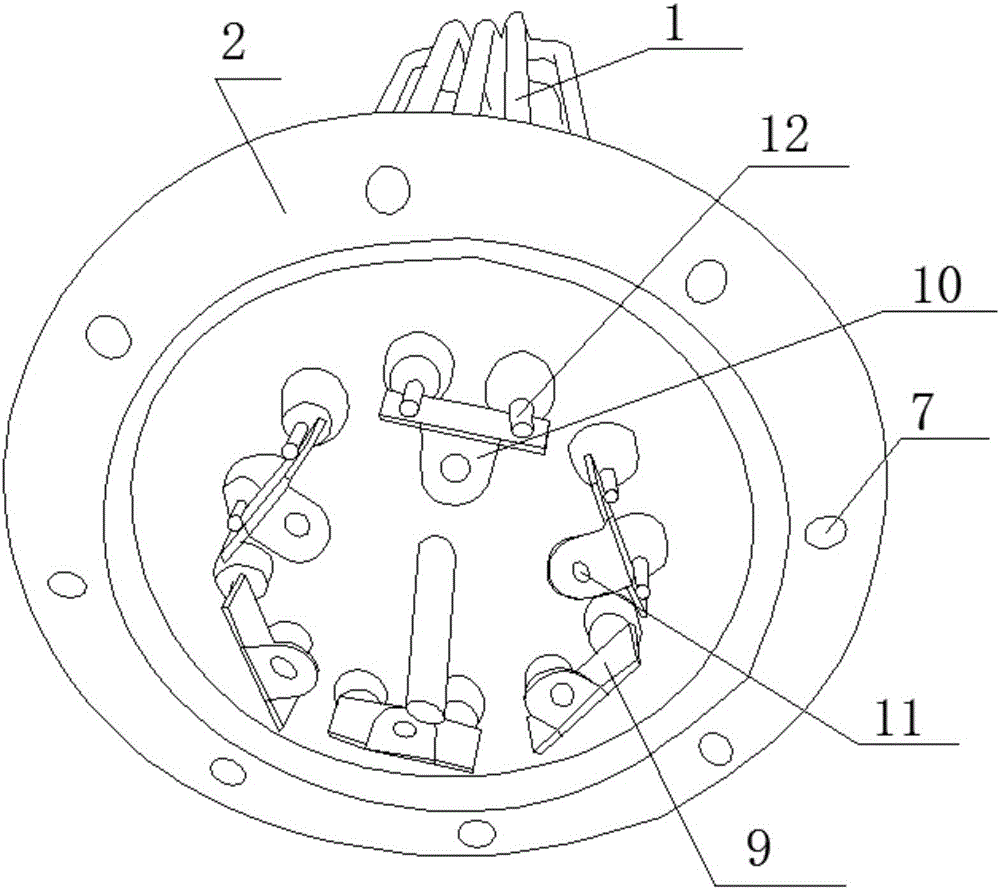

[0021] Such as figure 1 As shown, a flange package structure for installing electric heating tubes is provided with a raised surface 3 on the upper end surface of the flange plate 2, the electric heating tube 1 is installed on the raised surface, and a sealing ring 4 is sleeved on the periphery of the raised surface (also is the gasket), the sealing ring can have a first through hole 6, and the flange is provided with a second through hole 7 corresponding to the position of the first through hole, and the first through hole and the second through hole can be connected by a fastener The flange connection on the heating device (such as a water heating chamber) using the flange packaging structure improves the sealing performance and avoids water seepage caused by traditional installation.

[0022] The connection between the end portion 13 of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com