Splitting method of basic unit of honeycomb-shaped triangular conical mesh shell structure

A basic unit, triangular cone technology, applied in building structure, building material processing, construction, etc., can solve the problems of reducing construction efficiency and increasing safety risks, and achieves good firmness, convenient operation, and easy control of assembly quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

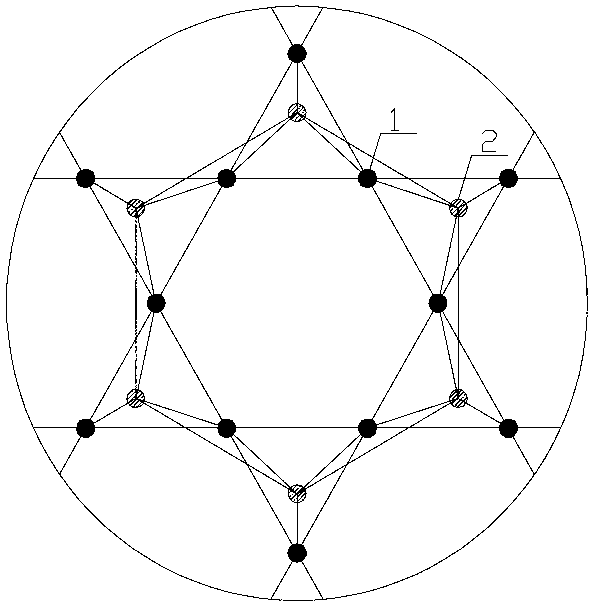

[0011] Such as figure 1 Shown: The honeycomb triangular pyramid structure is composed of a hexagon on the upper chord, a hexagon on the lower chord and six triangles, and the triangle and the hexagon share one side. A honeycomb type contains 6 upper string balls (1) and 12 lower string balls (2), the projection of the upper string balls is located in the triangle formed by the lower string balls, and the upper string balls and the triangular lower string balls are connected through the web bar (3).

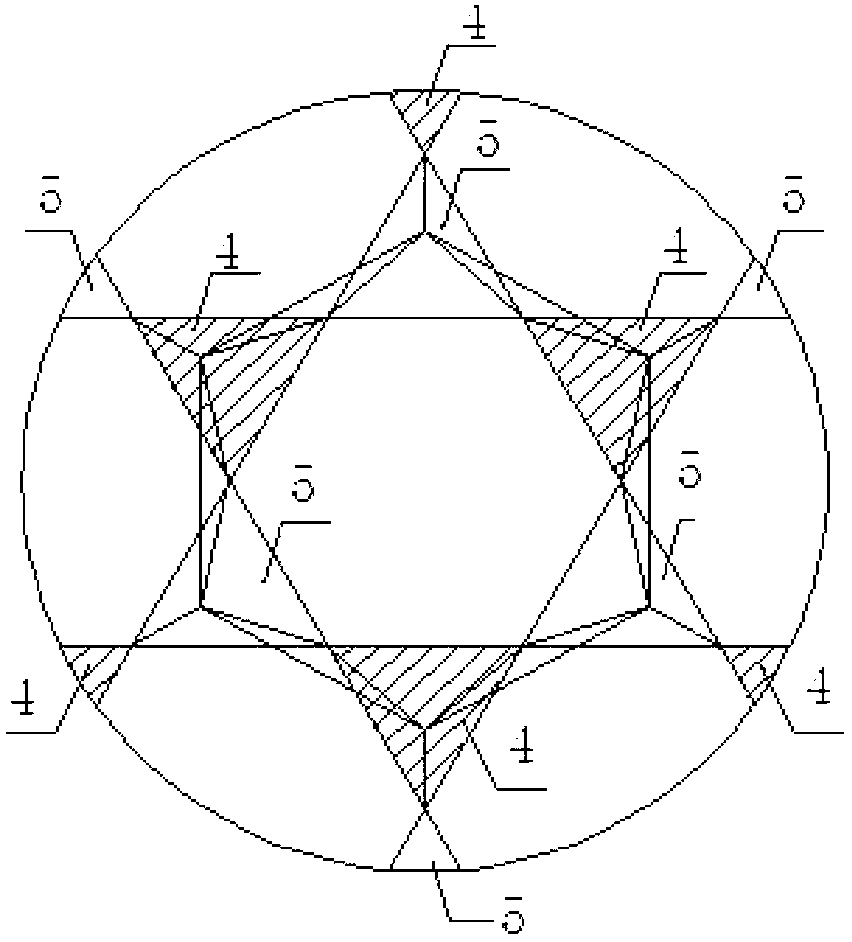

[0012] Such as figure 2 Shown: 4 is a triangular cone unit, and 5 is a triangular claw unit. Firstly, define a triangular pyramid unit including one upper chord, three lower chords, three webs, and three lower chords in the reticulated shell honeycomb unit, and then determine that there is only one upper chord in the three adjacent triangular pyramids 1. A triangular claw unit composed of three web rods. After splitting in this way, the ball joints and some rods of the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com