Sand shooting device for making slender sand cores by hand

A slender, sand core technology, applied in the direction of manufacturing tools, metal processing equipment, casting molding equipment, etc., can solve the problems of difficult sand filling, insufficient sand shooting, and unreal sand shooting, so as to avoid insufficient sand filling, High strength and good firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

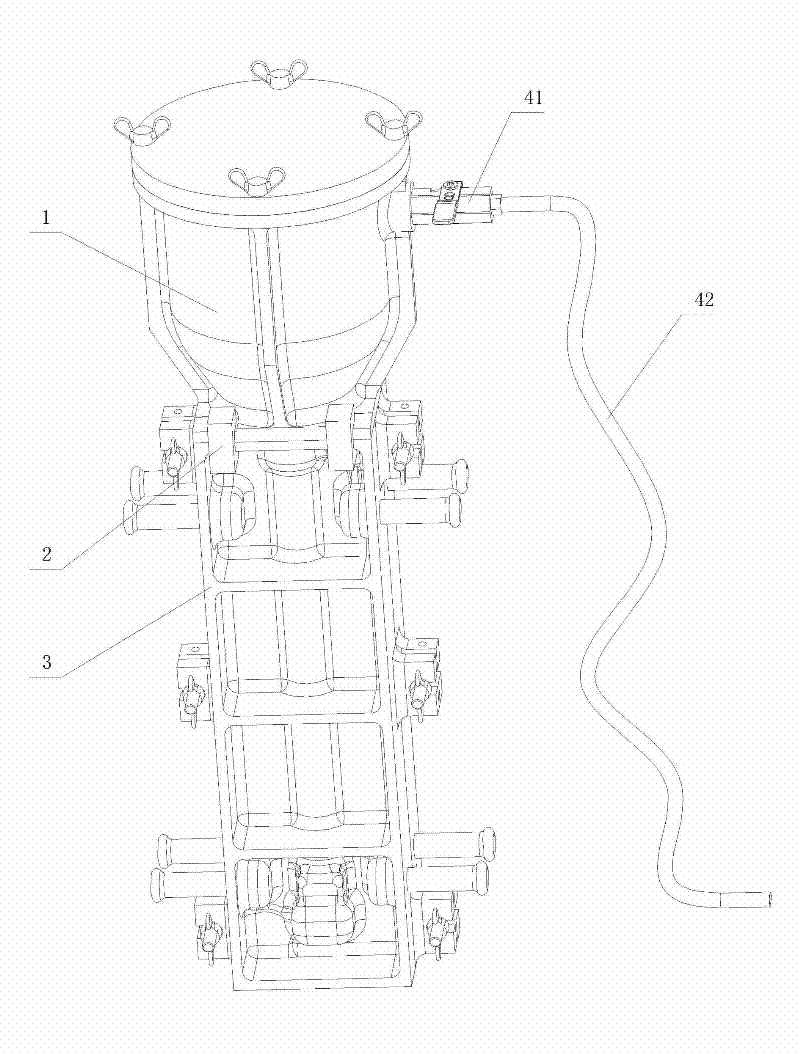

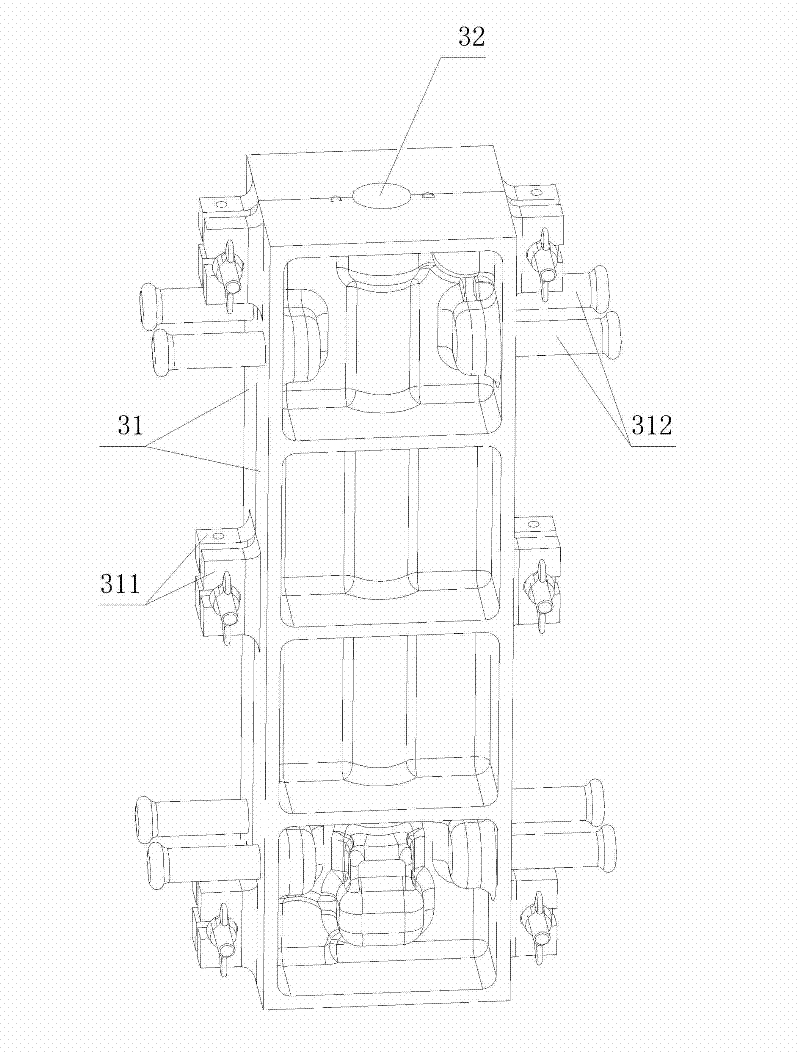

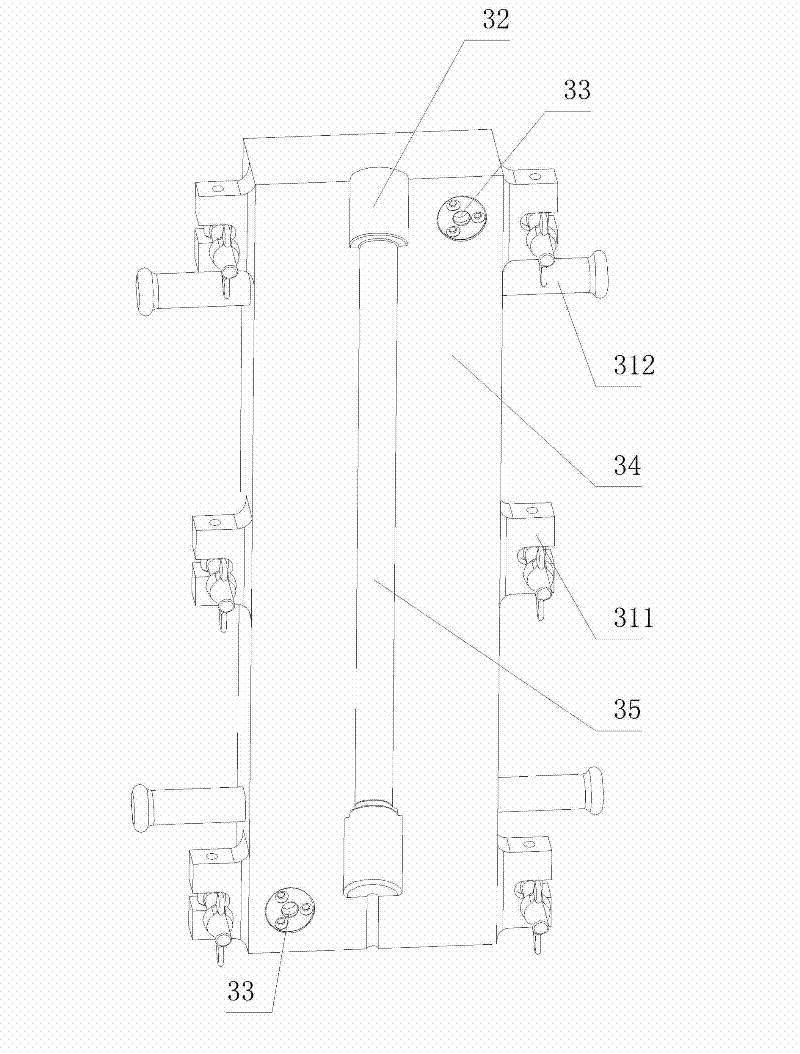

[0024] Depend on Figure 1 to Figure 6 As can be seen from the structural schematic diagram of the sand shooting device for hand-made slender sand cores of the present invention, it includes a core box 3 with a slender sand core cavity 35 inside, a sand shooting cylinder 1 with core sand and a gas source connected to it. The air supply device, the bottom of the sand shooting cylinder 1 is connected to the core box 3 and the sand shooting cylinder 1 is connected to the elongated sand core cavity 35 of the core box 3, and the air supply device is connected to the upper part of the sand shooting cylinder 1 .

[0025] The core box 3 is composed of two monomers 31 along the axial direction of the slender sand core, each monomer 31 has a half cavity, and each monomer 31 has lugs 311 on both sides , the corresponding lugs 311 of the two mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com