Batch making method for circular three-layer biofilm

A production method and biofilm technology, which are applied in medical science, surgery, etc., can solve the problems of biocomposite film degradation speed time performance indicators that cannot meet clinical needs, small fracture area, and large biocomposite film volume and area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

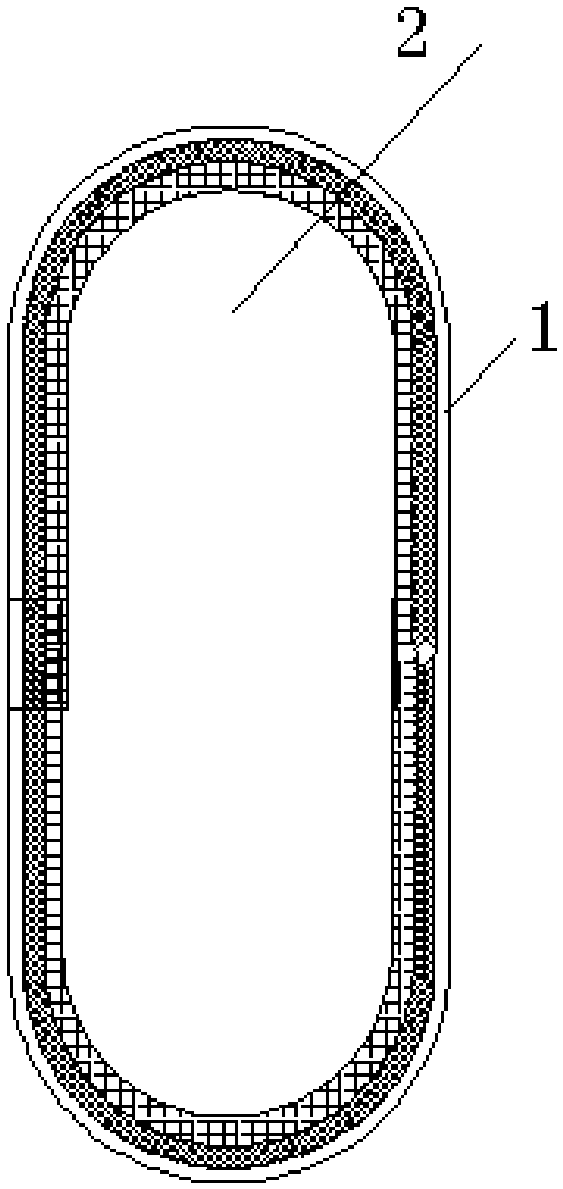

[0033] refer to figure 1 1. A method for producing a circular three-layer biofilm in batches, comprising the following steps:

[0034] 1) A model 2 with an elliptical cross-section and a "U"-shaped apex angle on the long side that coincides with the fracture line section is made in advance;

[0035] 2) The model is immersed in the first solution layer, the second solution layer, and the third solution layer in sequence. The first solution forms an elastic layer, which is a dense degradable or non-degradable biofilm. The second solution layer forms a drug layer, which encapsulates The drug slow-release system that can promote bone healing is made of degradable or absorbable substances that are biocompatible with human bone. The third solution layer forms a guiding layer, and the material is biocompatible with human bone. Degradable or non-degradable, absorbent or non-absorbable porous and loose substances;

[0036] 3) After the biological microstructure membrane 1 is air-drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com