Method for making model array of three-layer circular composite film

A production method and composite membrane technology, which are applied in medical science, surgery, etc., can solve the problems of ineffective fit, small fracture area, and large volume of biocomposite membrane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

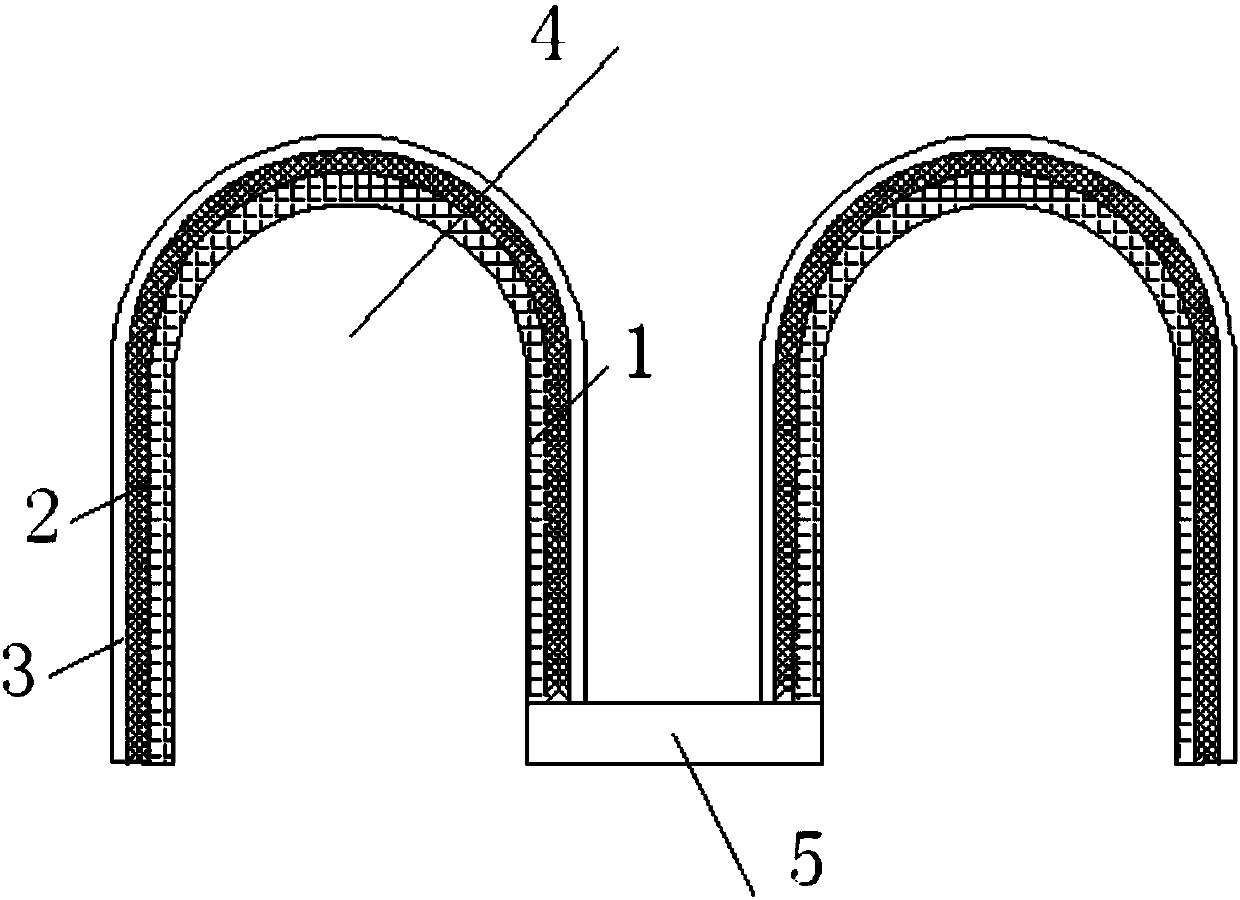

[0036] refer to figure 1 , the method for making the model array of the three-layer circular composite membrane, 1) make the model 4 whose apex angle section is "U" and coincides with the fracture line section in advance, and the "U" model 4 is combined into an array close to each other, and each The bottoms of each "U" model 4 are 3-5 mm apart from each other;

[0037]2) Wet elastic layer, drug layer, and guide layer are made respectively, the elastic layer 1 is a dense biodegradable or non-degradable biofilm, and the drug layer 2 is encapsulated with a drug slow-release system that can promote bone healing, The material is a degradable or absorbable material that is biocompatible with human bone, and the material of the guide layer 3 is a porous and loose material that is biocompatible with human bone, degradable or non-degradable, absorbent or non-absorbable;

[0038] 3) Cover the wet elastic layer on the model array, wrap the top corners of each model 4 in the array and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com