Sealing plate drive with hydraulic drive

A driving device and hole sealing technology, which is applied in fluid pressure actuating devices, motor vehicles, underwater ships, etc., can solve problems such as undesired hydraulic systems, energy consumption, noise, etc., and achieve compact structure, reduced overall size, The effect of simple integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

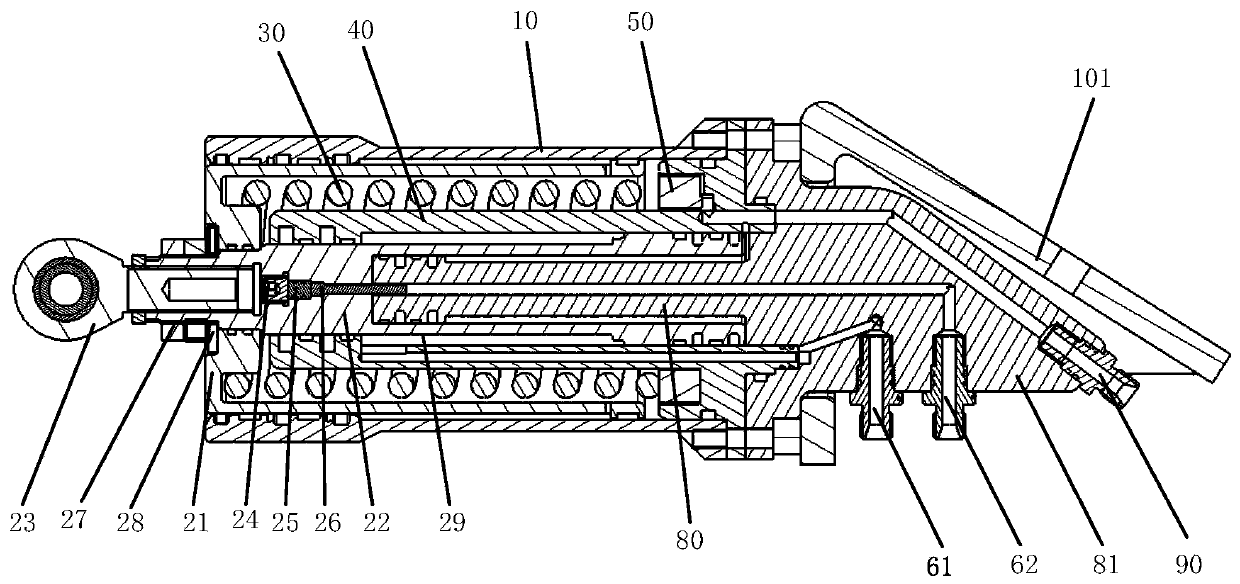

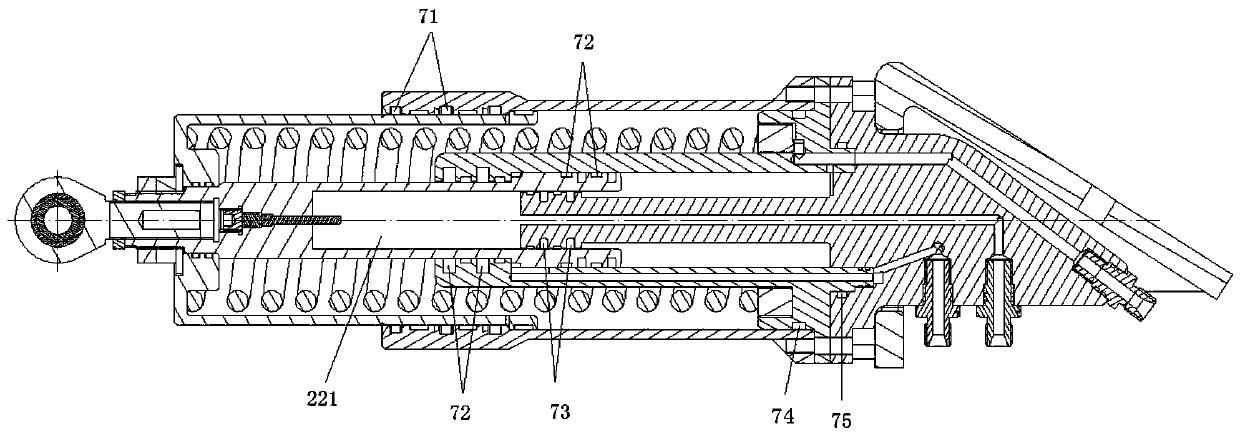

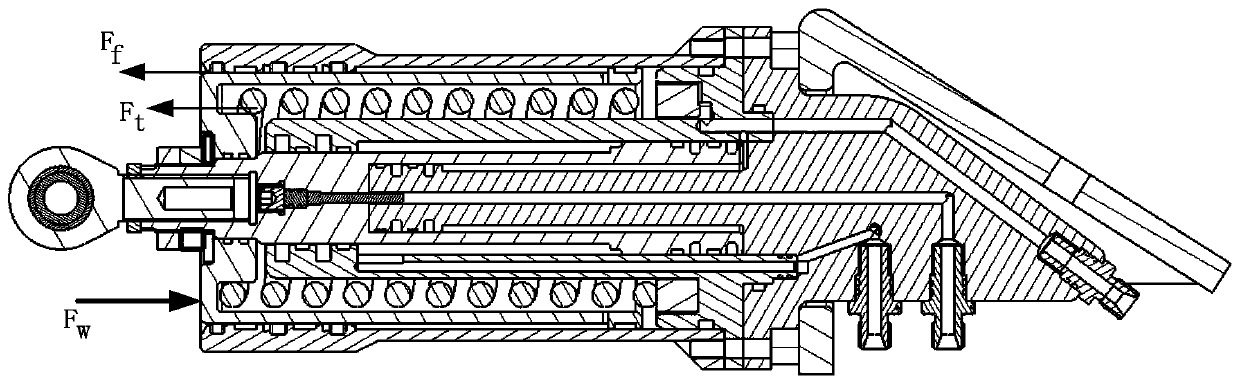

[0025] Such as Figure 1-2 As shown, it is a hydraulically driven sealing plate driving device 100 of a preferred embodiment of the present invention, which includes a connecting seat 81, an inner cylinder 40, an outer piston 22 and an inner piston 80 that are sequentially socketed from outside to inside, Both the rear end of the inner cylinder 40 and the rear end of the inner piston 80 are fixedly connected with the connecting seat 81, and the inner piston 80 and the connecting seat 81 are connected into one body. The middle and rear part of the outer piston 22 is provided with an inner chamber 221 configured with the inner piston 80 , and the inner cylinder 40 is provided with an outer chamber 29 configured with the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com