Test device and test method for testing waterproof performance of pipe segment joint sealing gaskets

A sealing pad waterproof and test device technology, which is applied in fluid tightness testing, measuring devices, liquid tightness measurement using liquid/vacuum degree, etc., can solve problems such as inconsistencies in actual engineering, achieve reliable design basis, and facilitate observation and record the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

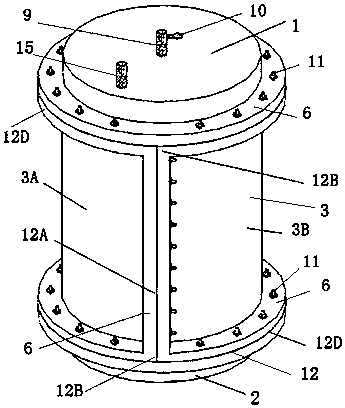

[0095] The device for testing the waterproof performance of the segment seam gasket in this embodiment can simulate various types of seams formed by staggered splicing of tunnels.

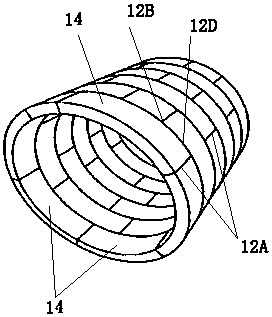

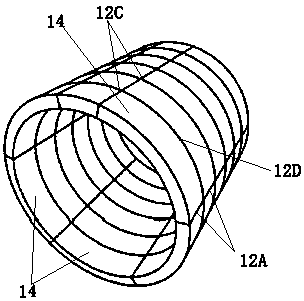

[0096] Such as Figure 3-Figure 22 As shown, the segment joint gasket waterproof performance test device includes a sleeve 3 with openings at both ends, and sealing covers installed at both ends of the sleeve 3, including a first sealing cover 1 and a second sealing cover 2, wherein,

[0097] The sleeve 3 includes a plurality of sleeve blocks. In this embodiment, the sleeve 3 includes two sleeve blocks, the first sleeve block 3A arranged on the left side and the second sleeve block 3B arranged on the right side , the two sleeve blocks are spliced to form the overall structure of the sleeve;

[0098] Such as Figure 16-Figure 22 As shown, the splicing surface of each sleeve block is provided with a splicing groove 7 for installing a gasket, and the end of the sleeve 3 is provided with an end gro...

Embodiment 2

[0142] The segment seam gasket waterproof performance test device of this embodiment is basically the same as that in Embodiment 1, and the cross section of the sleeve is also circular. The difference is that the sleeve 3 includes a first sleeve 31 and a second sleeve 31. The sleeve 32, the first sleeve 31 and the second sleeve 32 are respectively spliced by sleeve blocks, and the two have part or all of the seams aligned, such as Figure 23 and 24 shown.

[0143] The sleeve 3 includes a first sleeve 31 and a second sleeve 32 with butted ends, and the first sleeve 31 and the second sleeve 32 are all made of two identical semicircle sleeve blocks (as in embodiment 1 The first sleeve block 3A and the second sleeve block 3B) are spliced along the axial direction, the seam of the first sleeve 31 is aligned with the splicing of the second sleeve 32, and the first sleeve 31 and The relative position between the second sleeves 32 is adjustable.

[0144] In actual engineering, ...

Embodiment 3

[0148] This embodiment provides an experimental method for the waterproof performance of the segment seam gasket, which is used to test the test device in embodiment 1 or embodiment 2, such as Figure 3-Figure 24 shown, including the following steps:

[0149] a. Install the gasket 13 of the sleeve block and assemble the sleeve block, respectively install the gasket 13 in the splicing groove 7 and the end groove 5 of each sleeve block, and keep the gasket 13 and the sleeve block Relatively fixed, each sleeve block is assembled to form an overall sleeve structure. In embodiment 1, it is enough to assemble the first sleeve block 3A and the second sleeve block 3B. In embodiment 2, the first sleeve 31 should be assembled respectively. The first sleeve block 3A and the second sleeve block 3B, and the first sleeve block 3A and the second sleeve block 3B assembling the second sleeve 32, and then the first sleeve 31 and the second sleeve 32 to assemble;

[0150] b. Install the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com