Droplet assemblies and methods for producing droplet assemblies

一种组件、主体的技术,应用在液滴的组件,生产这些组件领域,能够解决限制组件有用性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

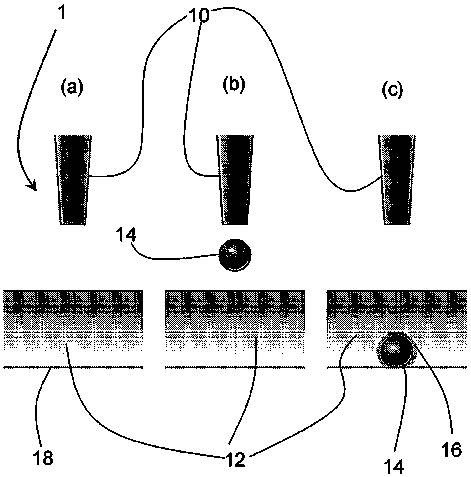

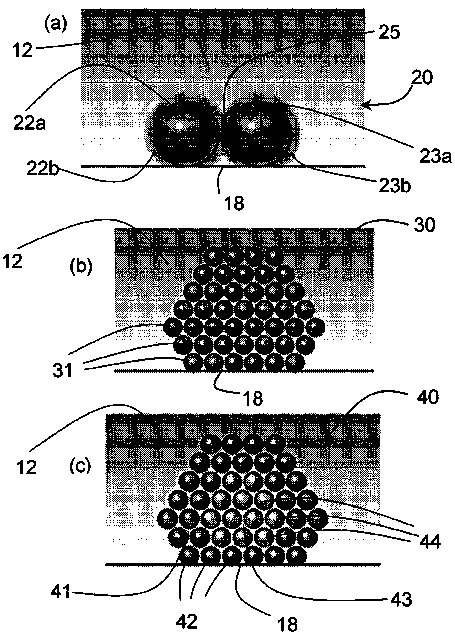

[0260] An attempt was made to produce an assembly containing 48 droplets arranged in a cubic lattice using droplet forming solution D1. Each droplet is about 3 millimeters in diameter. Where component preparation is possible (e.g., where bath infiltration is possible), the completed component is left in the bath for 2 min after build to ensure sufficient shell formation to support the structure. Remove components from bath using a spoon and absorb excess bath with paper towels. The structure of the component is evaluated by photographing the component from multiple angles, including the crystallographic orientation corresponding to the lattice structure. Where the components are edible, their taste is also tested by ingestion.

[0261] The droplet forming solution was dispensed using a peristaltic pump and nozzle located 10 cm above the bath. The peristaltic tubing has an inner diameter of 1 mm and an outer diameter of 3 mm. The nozzle consists of a disposable 10 μL pipett...

Embodiment 2

[0266] An attempt was made to produce assemblies in bath B2 in exactly the same manner as described in Example 1 using drop forming solution D3. Droplets penetrated into the bath with about 100% probability, and good printing fidelity was obtained at bath temperatures of 21°C and 27°C. Example 3 An attempt was made to produce an assembly in Bath B1 in exactly the same manner as described in Example 1 using drop forming solution D6 at room temperature.

[0267] Immediately after incorporating the final droplet into the assembly, remove the assembly from the bath. When the assembly was removed from the bath, it was noted that individual droplets on the periphery of the assembly were distinct and protruded significantly from the assembly. The components were extracted and the encapsulated gel film was noted to have a soft mouthfeel. After the final droplet was integrated into the assembly, another assembly was removed from the bath within approximately 15 minutes. When the ass...

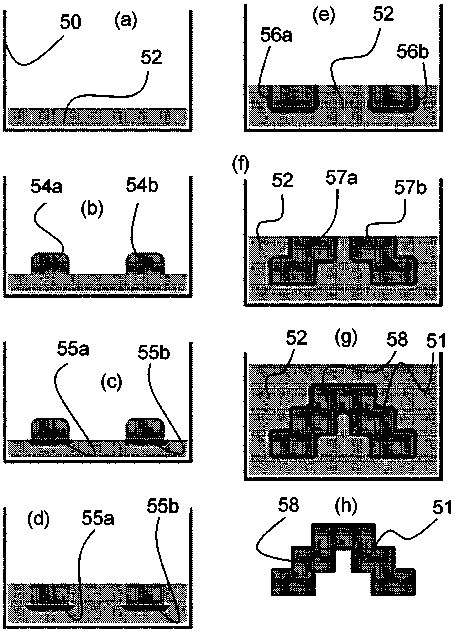

Embodiment 4

[0268] An attempt was made to produce assemblies in bath B1 in exactly the same manner as described in Example 1 using drop forming solution D6 at room temperature. The depth of the bath solution is approximately equal to the height of the intended structure of the component. However, it was found that the droplets above the uppermost layer of the component were not fully immersed in the bath, these droplets were not fully encapsulated, and thus their droplet solutions were exposed to air. It was concluded that output at an excess bath depth was required to allow the topmost droplet of the component to be completely encapsulated. Example 5 Attempting to use drop forming solution D6 at room temperature, an assembly was produced in Bath B1 in the same manner as described in Example 1, except that in Example 5 the time interval between dispensing successive droplets was 1 second outside. The reduced time interval between droplets causes each droplet to sink in the bath, while p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com