Anti-slip shoe sole

A technology of anti-skid blocks and anti-skid teeth, which is applied in the directions of soles, footwear, clothing, etc., can solve the problems of unsatisfactory anti-skid function and slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

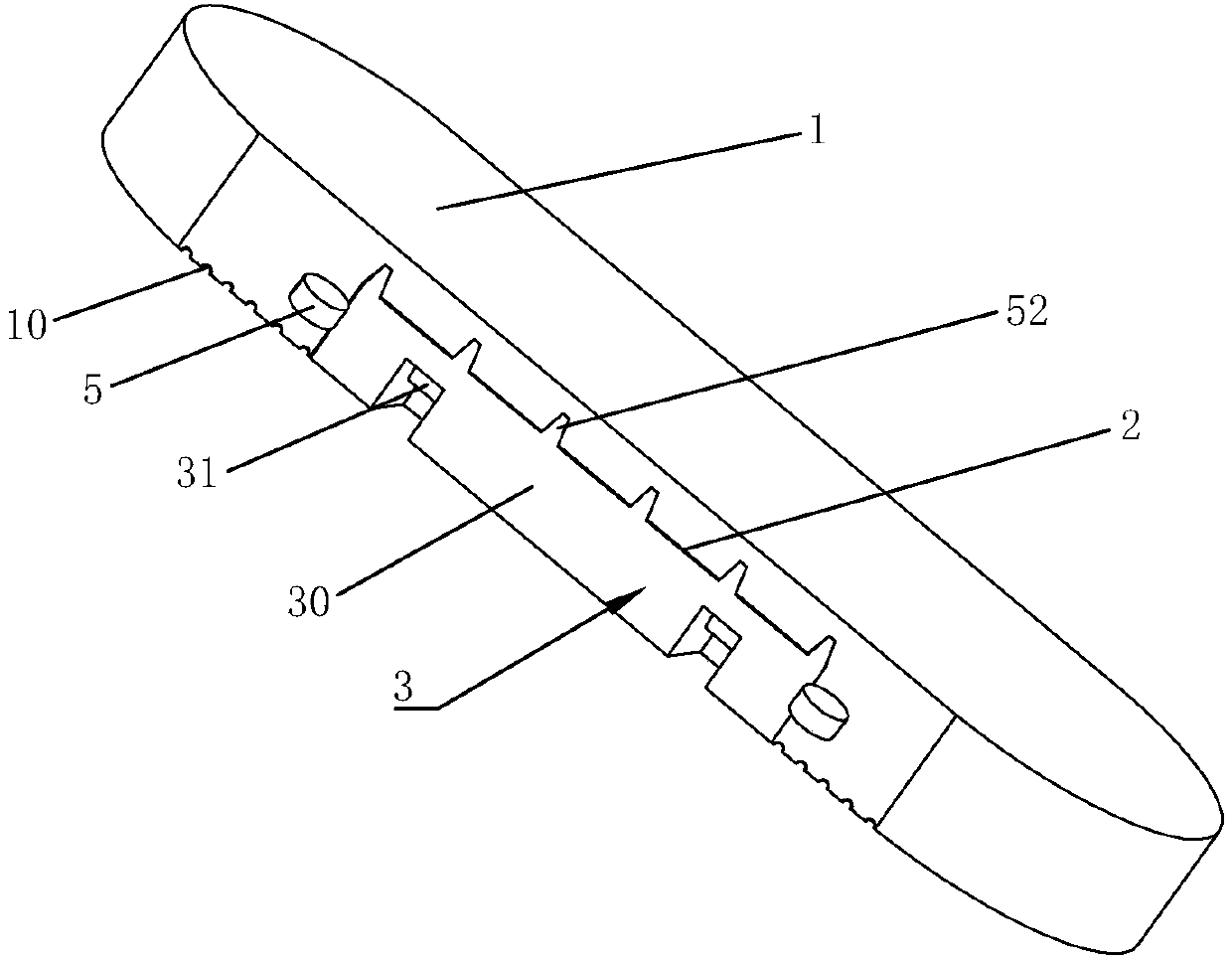

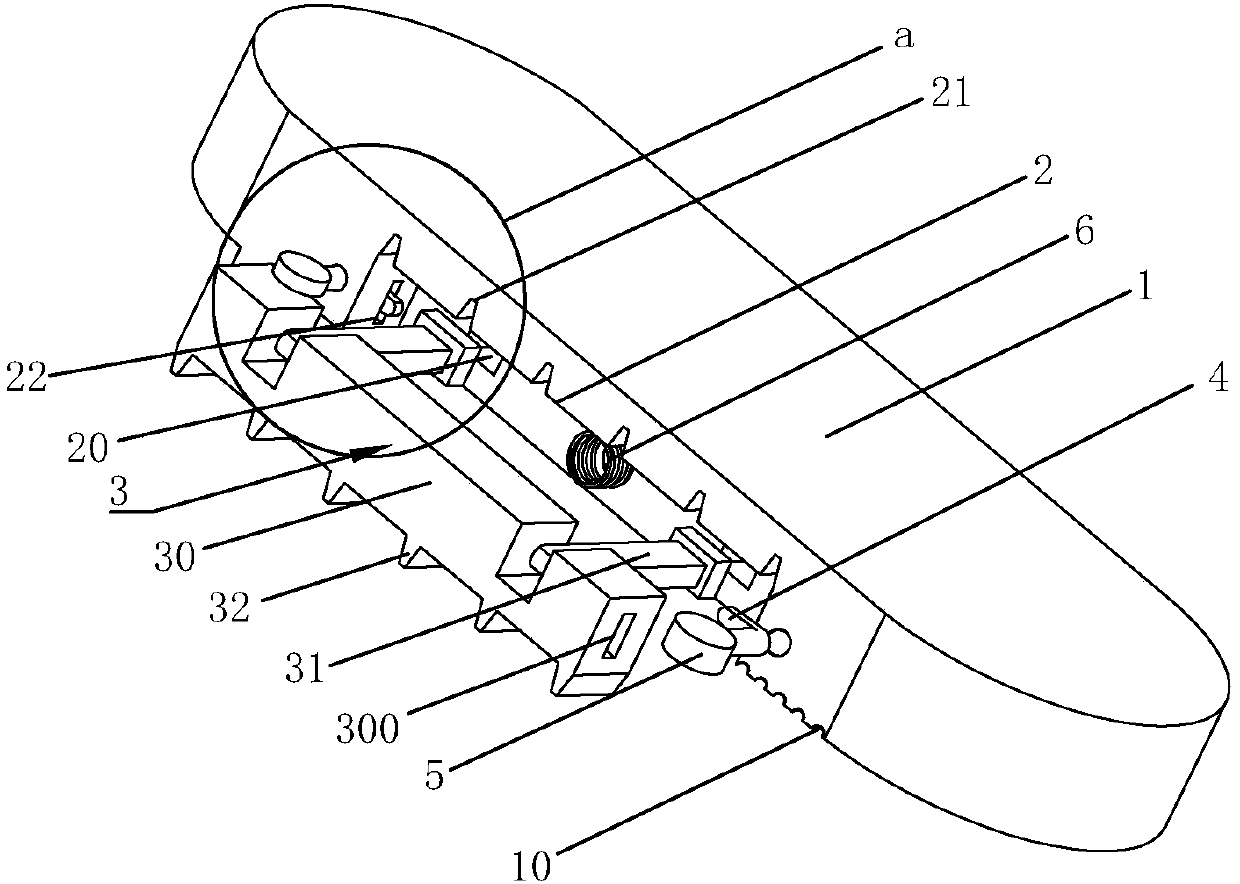

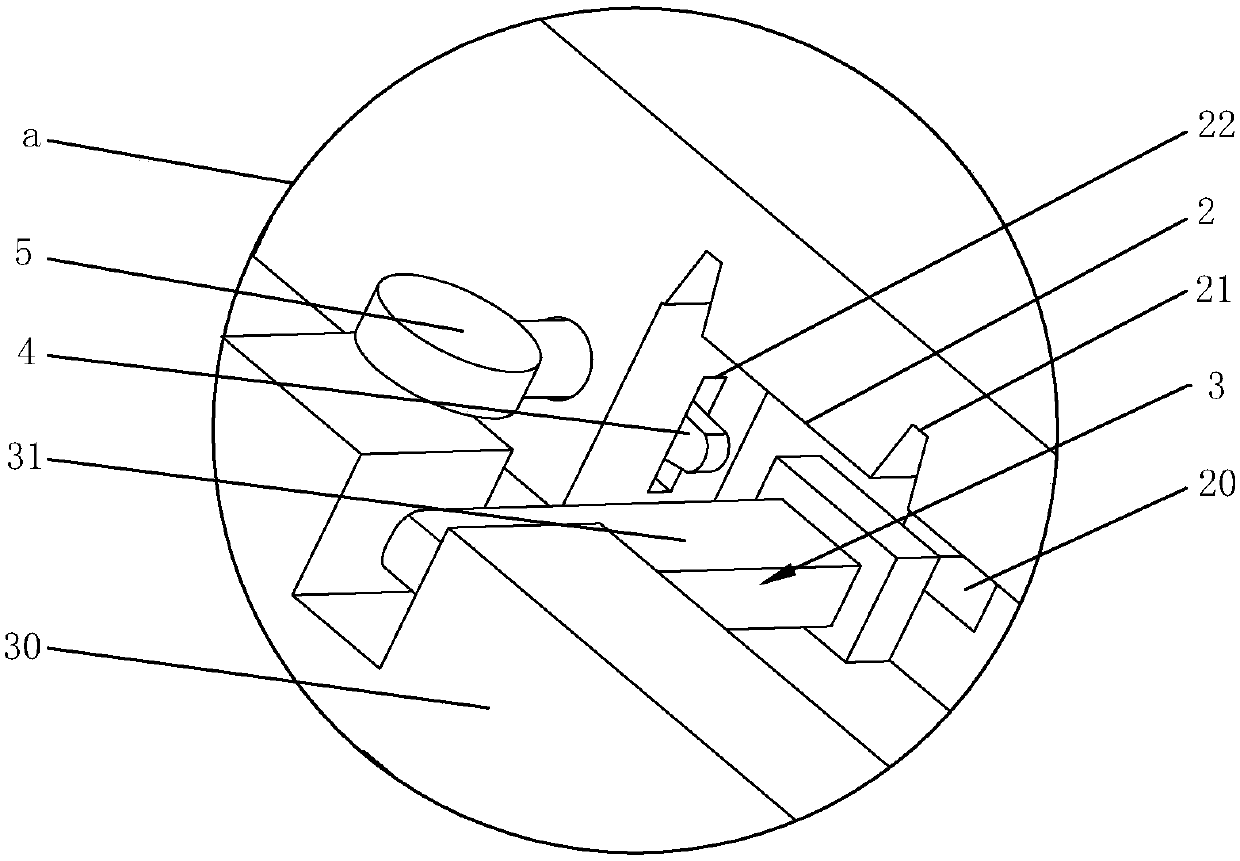

[0012] Reference Figure 1 to Figure 3 The embodiments of the present invention are further described.

[0013] The present invention discloses a non-slip shoe sole, comprising a shoe sole 1. A number of anti-slip grooves 10 are provided on the lower surface of the shoe sole 1, and grooves 2 are provided on both sides of the lower surface of the shoe sole 1. The grooves 2 bottom Both ends of the wall are provided with sliding grooves 20, the groove 2 is also provided with an anti-skid device 3, the anti-skid device 3 includes an anti-skid block 30, both ends of the anti-skid block 30 are provided with rotatable matching The sliding rod 31 can be embedded in the sliding groove 20 to slide back and forth, the anti-skid block 30 is provided with anti-skid teeth 32 arranged along the length of the anti-skid block 30, and the groove 2 The side wall is also provided with a fixing groove 21 for embedding the anti-slip teeth 32. The bottom wall at both ends of the groove 2 is provided ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap