Fan main machine fixing mechanism of blade welding equipment for micro-motor fans

A technology for fan blades and welding equipment, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inaccurate welding positions, blade angle deviation, and inability to achieve unified production standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

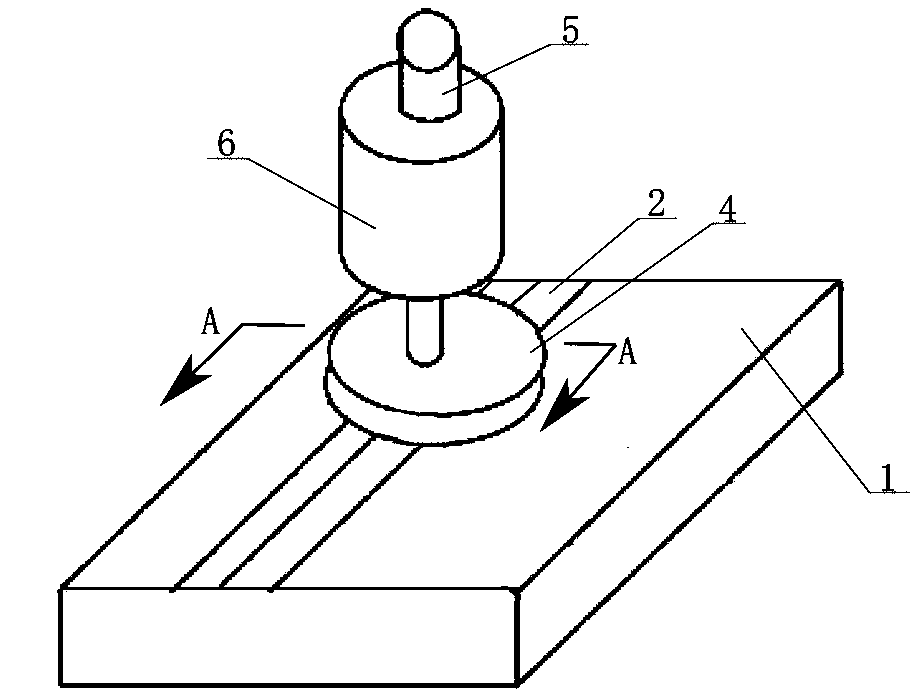

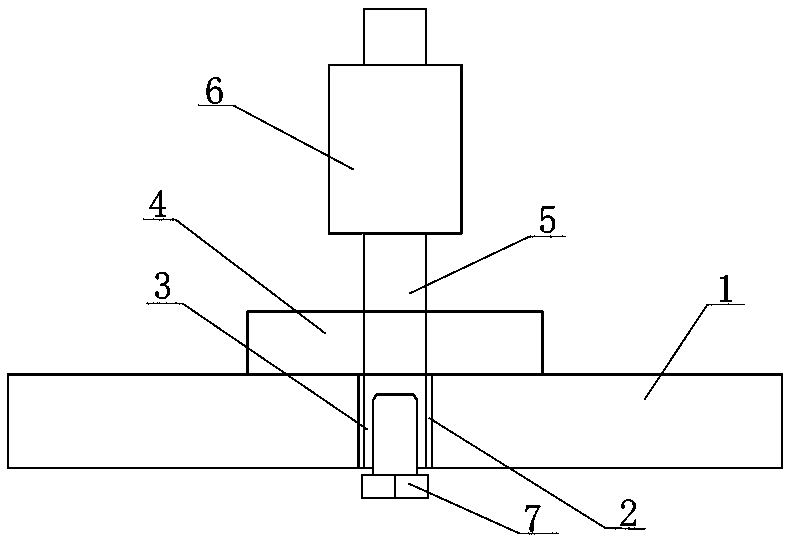

[0009] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, the fan main body fixing mechanism of a micro-motor fan blade welding equipment according to the present invention includes a working platform 1 arranged on the frame, and the working platform 1 is provided with at least one positioning and fixing groove 2, A mobile platform 4 is installed on it through a positioning column 3 that can be relatively moved by being inserted into the positioning and fixing groove 2. The mobile platform 4 is provided with a vertical column 5, and the column 5 is provided with a height-adjustable fan positioning Seat 6.

[0010] The positioning column 3 under the mobile platform 4 of the present invention is a screw rod, and the screw rod is tightened from the bottom of the working platform 1 through a nut 7 configured at the end of the screw rod, so that the mobile platform 4 is fixed on any position of the positioning a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com