Teflon pipe precise cutting device and method

A Teflon tube and cutting technology, used in metal processing and other directions, can solve the problems of easy cutting into oblique openings, poor control, poor incision quality, etc., to improve length accuracy, eliminate bending or flattening, incision, etc. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

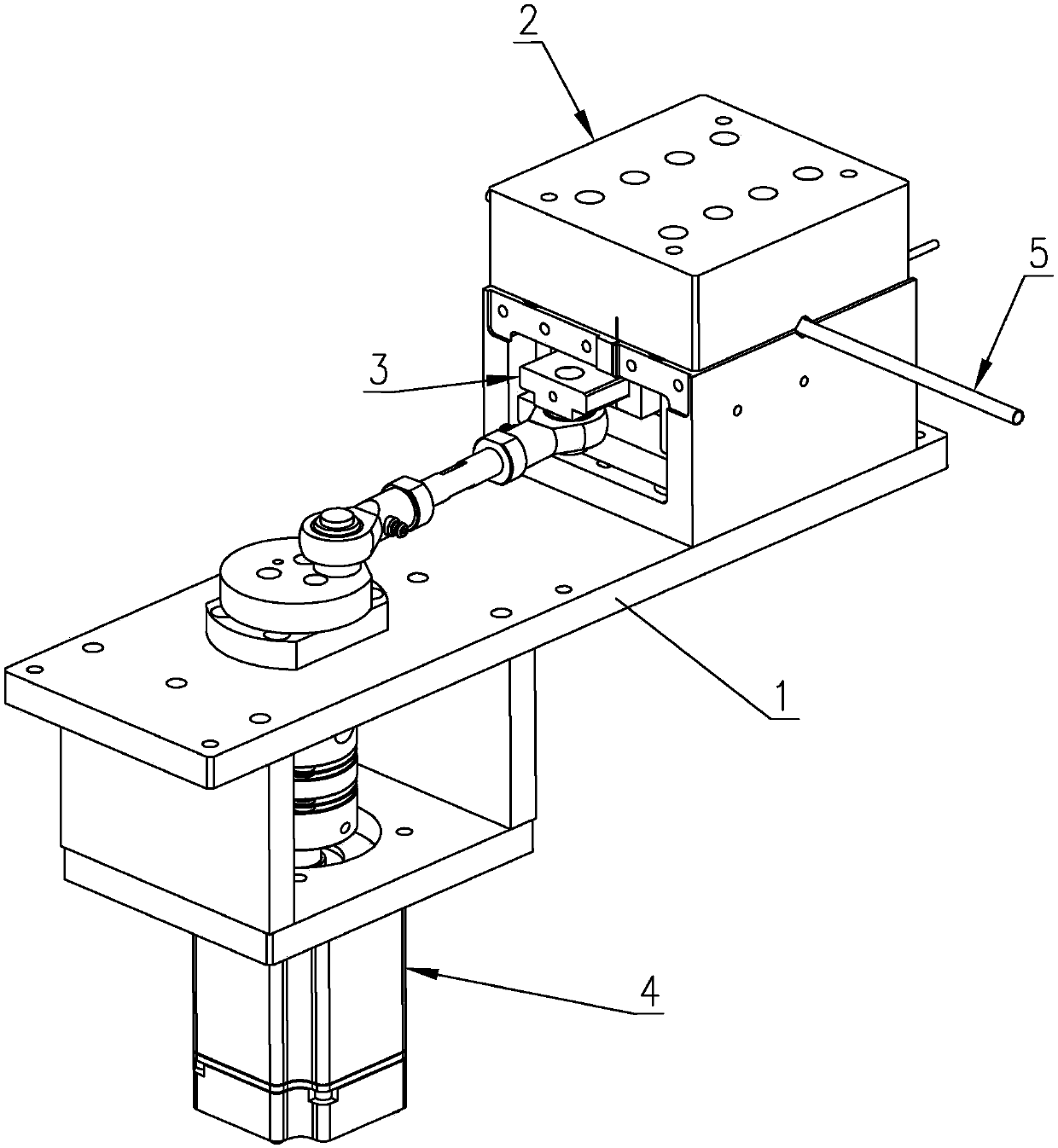

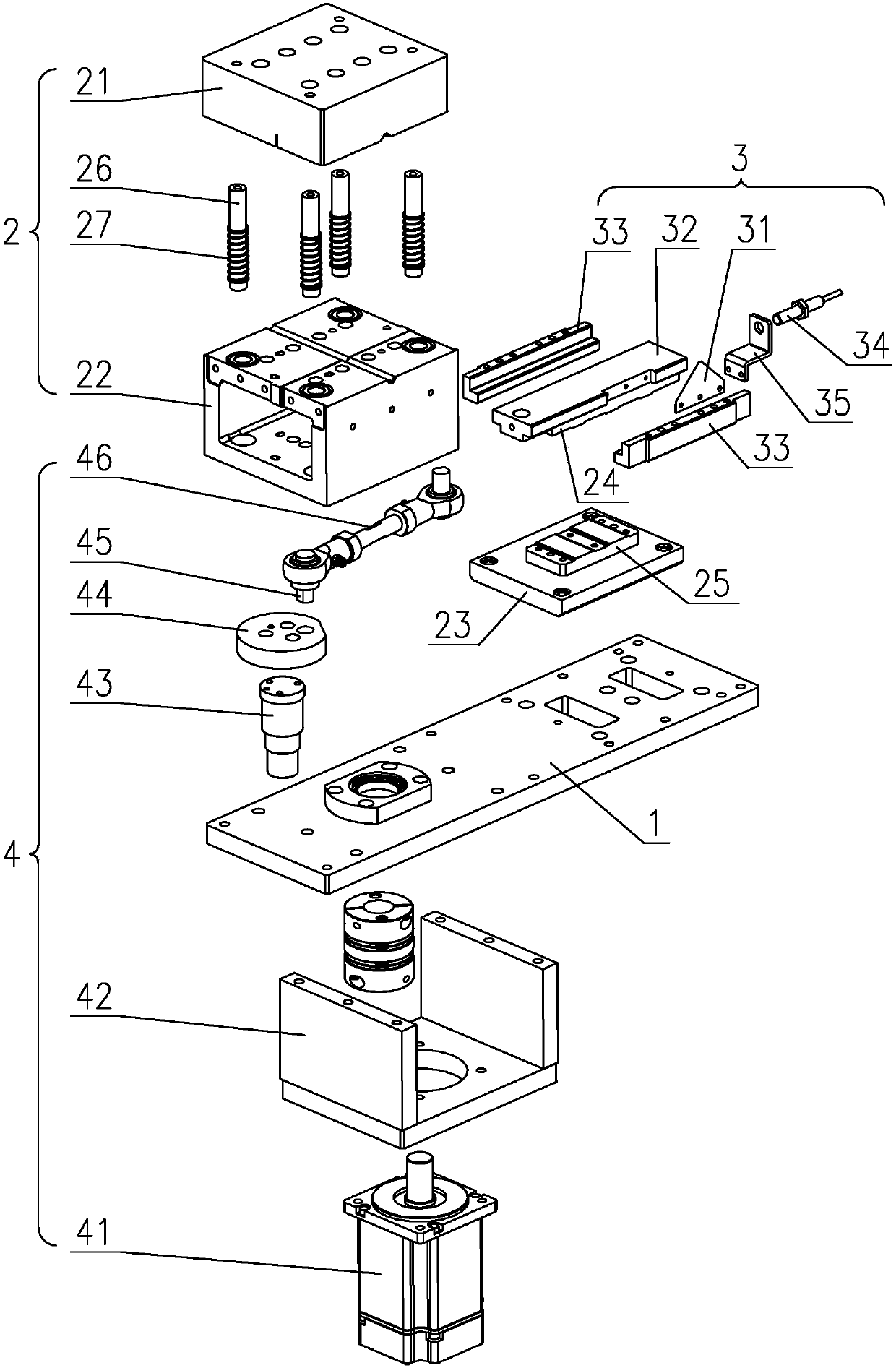

[0062] Such as Figure 1 to Figure 6 As shown, a Teflon tube precision cutting device includes a frame, a clamping mechanism 2, a cutting mechanism 3, and a cutting drive mechanism 4, and the frame is provided with a frame table 1; the clamping mechanism 2 is fixedly installed on the rack table 1, the cutting mechanism 3 is placed in the clamping mechanism 2, the cutting driving mechanism 4 is fixedly installed on the rack table 1, and the cutting driving mechanism 4 drives the cutting The mechanism 3 works to cut off the Teflon tube 5 clamped in the clamping mechanism 2 .

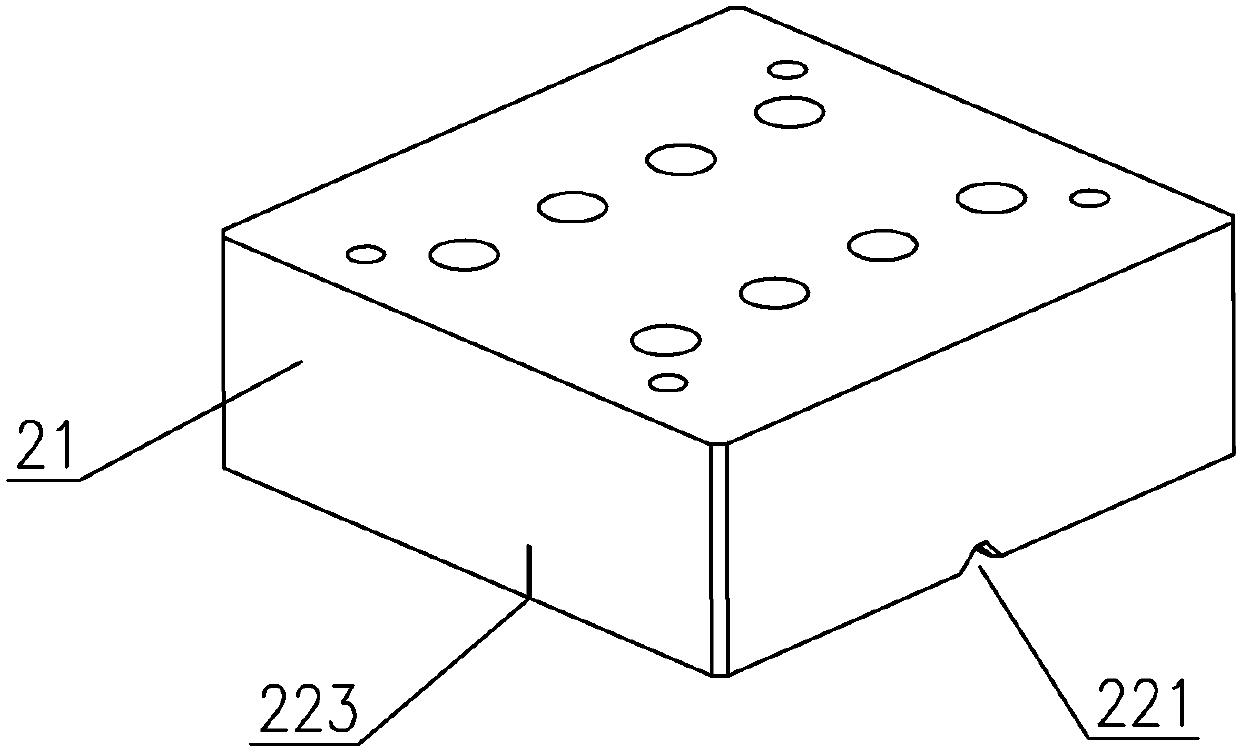

[0063] Specifically, such as Figure 1 to Figure 6As shown, the clamping mechanism 2 includes an upper splint 21, a lower splint 22, a base plate 23, an upper drive plate 24, a lower drive plate 25, 4 columns 26, and 4 spring elastic elements 27. The upper splint 21, the lower splint The splint 22 is longitudinally provided with a through groove 221 for clamping the Teflon tube. The through groove 221 is...

Embodiment approach 2

[0067] The second embodiment is basically the same as the first embodiment, except that the turntable 44 is replaced by a cam, and the cam is provided with a cam groove, and the pin shaft 45 is placed in the cam groove and is driven and connected by the cam groove.

[0068] The present invention also provides a kind of Teflon tube precision cutting method, it comprises the following steps:

[0069] A. Preparation: The external automatic tube delivery equipment automatically transports the fixed-length Teflon tube 5 into the clamping mechanism 2;

[0070] B. Cutting: The cutting drive mechanism 4 works to drive the cutting mechanism 3 to work and cut off the Teflon tube 5 clamped in the clamping mechanism 2;

[0071] C. Output: The external automatic tube delivery equipment automatically transports the fixed-length Teflon tube 5 into the clamping mechanism 2 and ejects the cut Teflon tube 5 forward;

[0072] Return to step B, repeat cutting and outputting.

[0073] Specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com