An intermittent pre-engine ventilation plate structure

A pre-blower, intermittent technology, applied in the field of foam processing machinery, can solve the problems of unevenness, different density of foam products, and the ventilation volume of the ventilation plate cannot meet the requirements, so as to achieve the effect of improving product quality and uniform heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

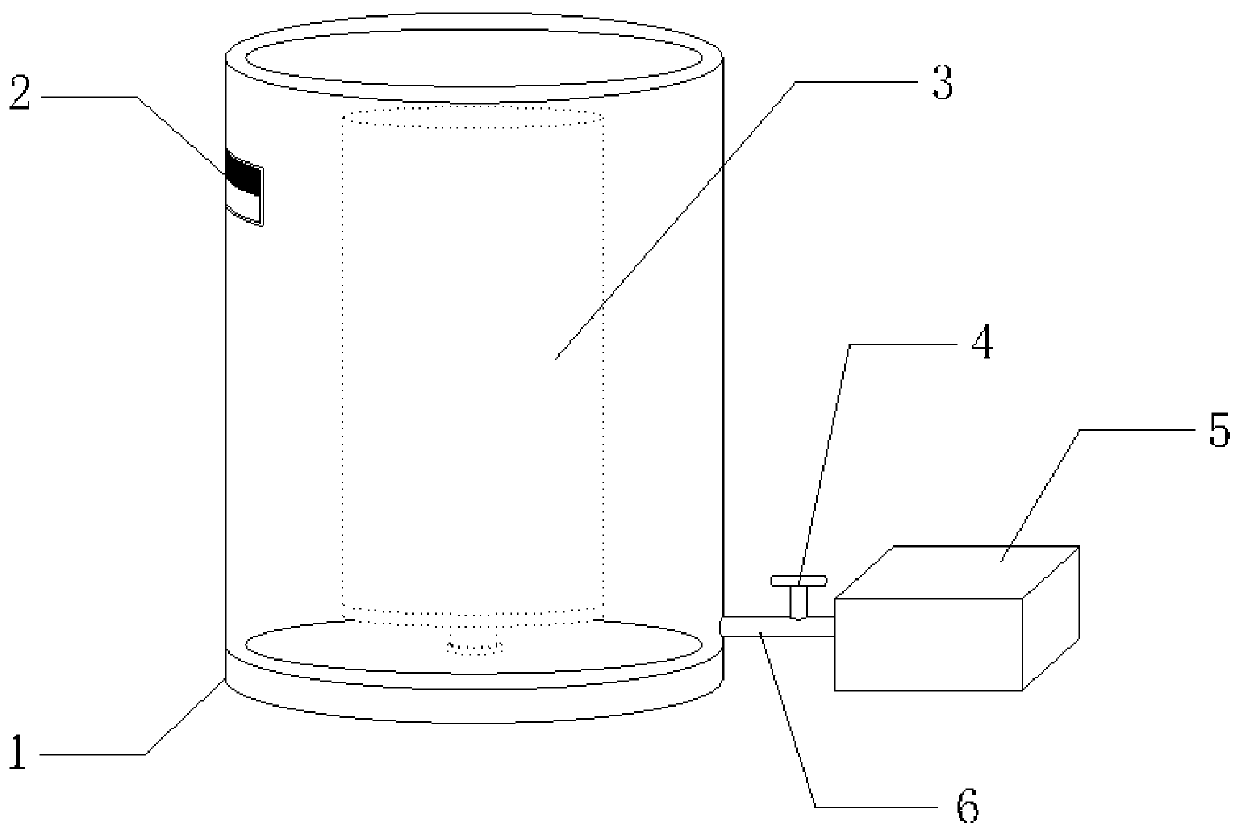

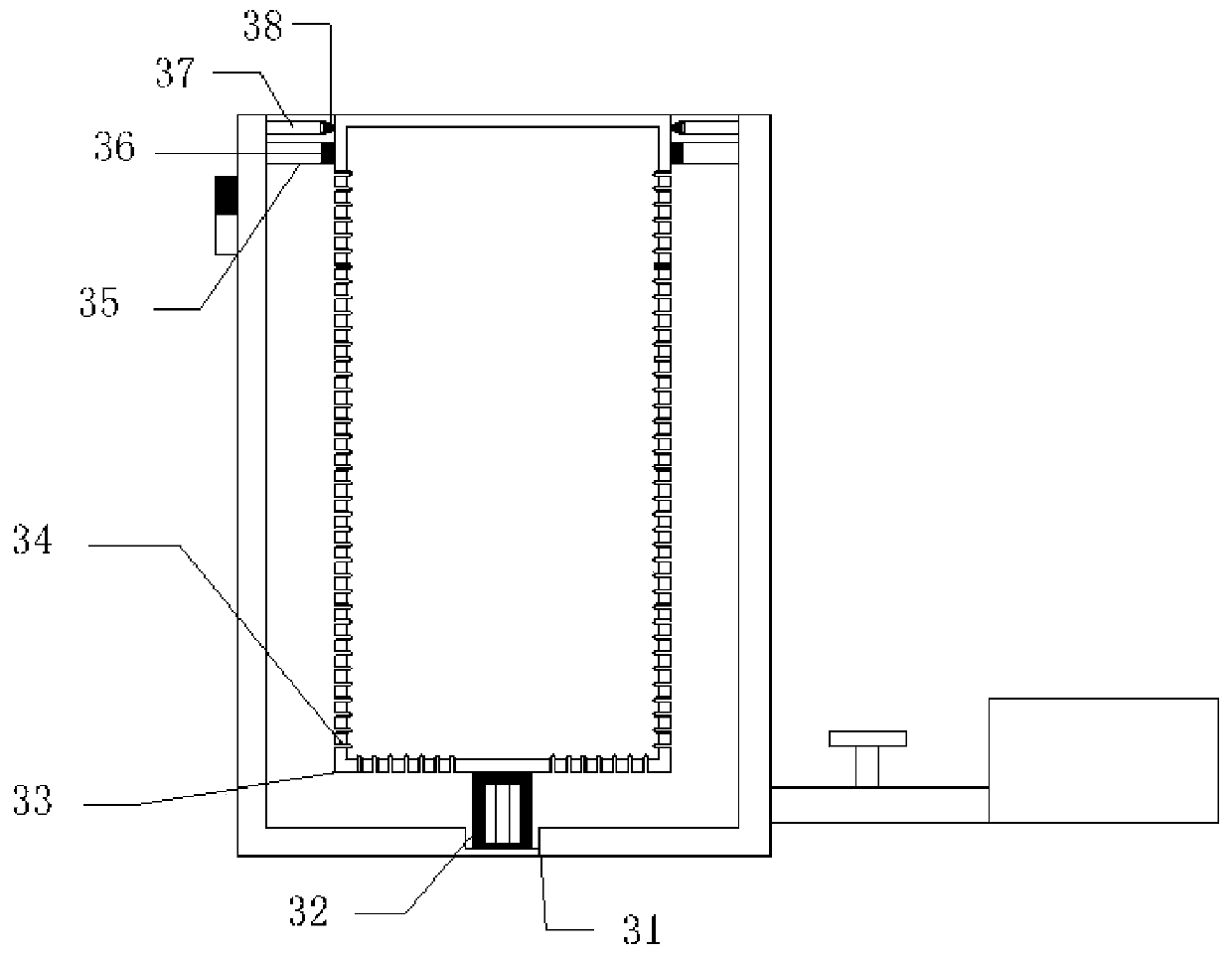

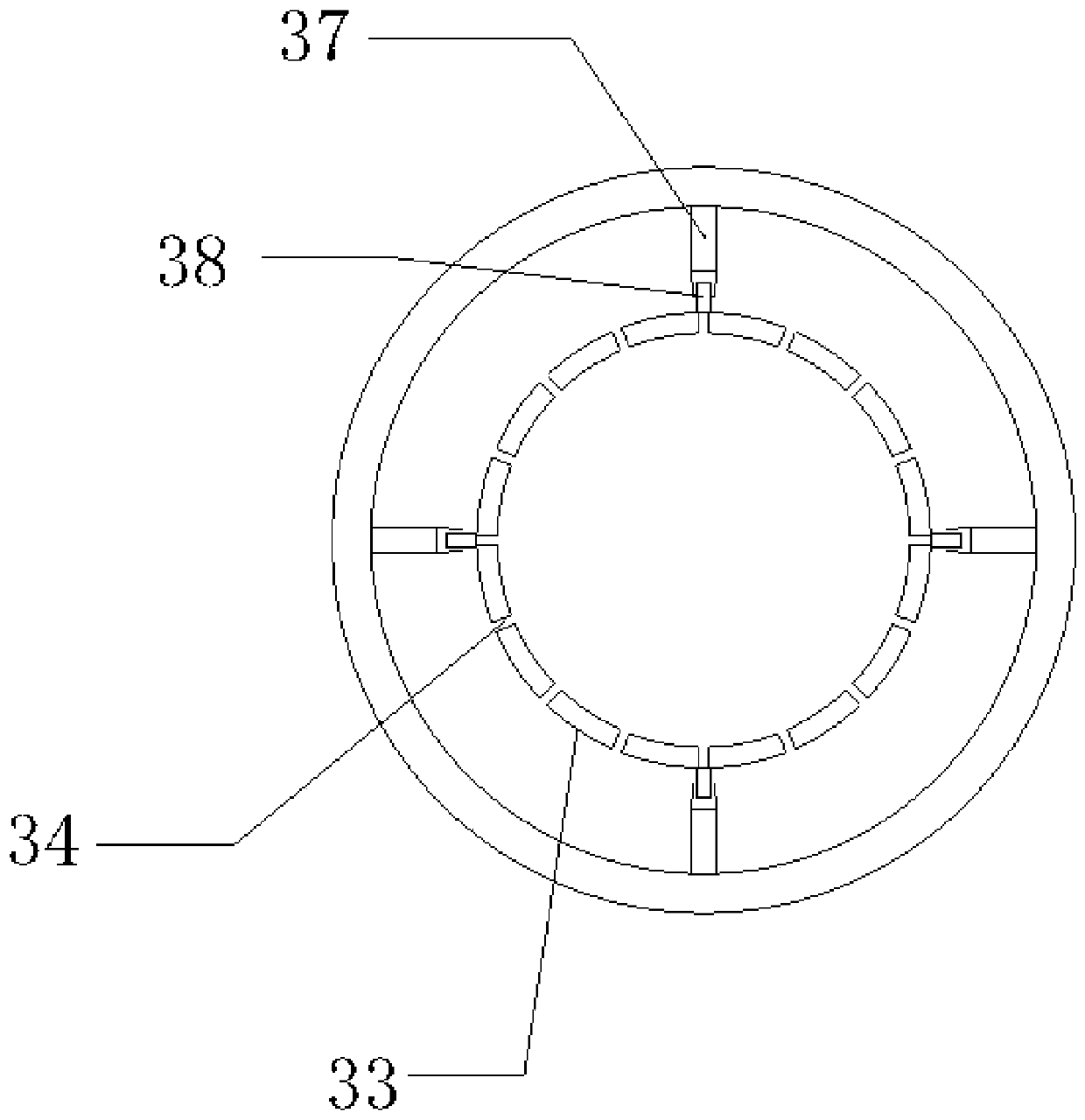

[0019] Specific embodiments: when the present invention is in use, open the ventilation valve 4, and the steam in the air pump 5 enters the cavity between the outer barrel 1 and the inner barrel 33 through the branch pipe 6. There is a support ring 35 and a rubber sealing ring 36, which prevents the steam from flowing out from the upper part. The steam in the outer barrel 1 and the inner barrel 33 can only flow out from the vent hole 34 provided on the annular side and lower end of the inner barrel 33 at this time, and turn on the control switch at the same time 2. The electric shaft 32 converts electrical energy into mechanical energy, and the electric shaft 32 drives the inner barrel 33 to rotate, and the steam discharged from the exhaust hole 34 is evenly distributed inside the inner barrel 33, so that the raw material is heated evenly when heated, thereby improving product quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com