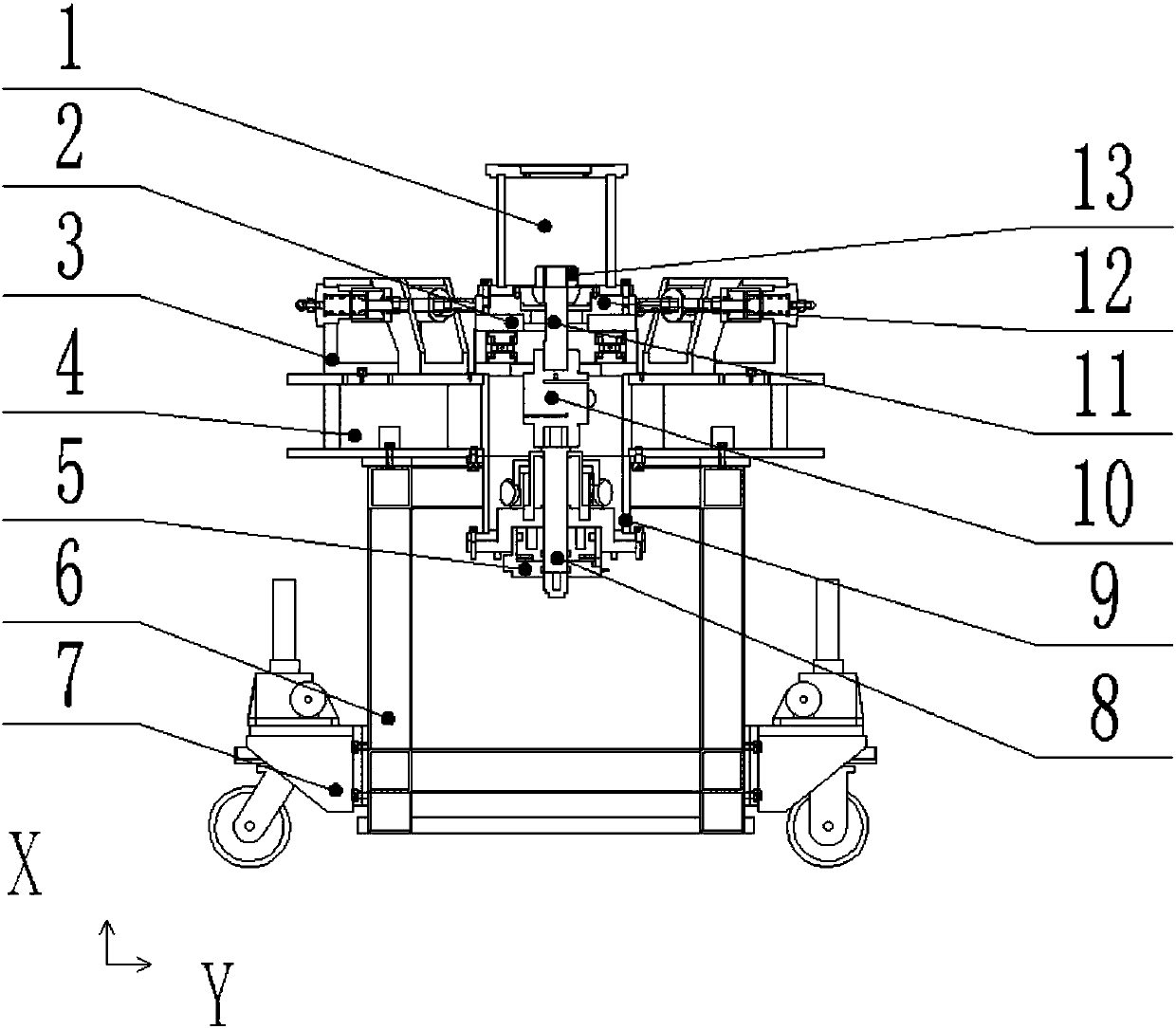

Piezoelectric test device for high thrust solid rocket motor

A technology of solid rockets and testing devices, which is applied in the fields of measurement, control and sensing. It can solve the problems of reliability of test results, complex engine installation and debugging, and low natural frequency of test benches. It achieves simple installation and debugging, solves complex installation, The effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

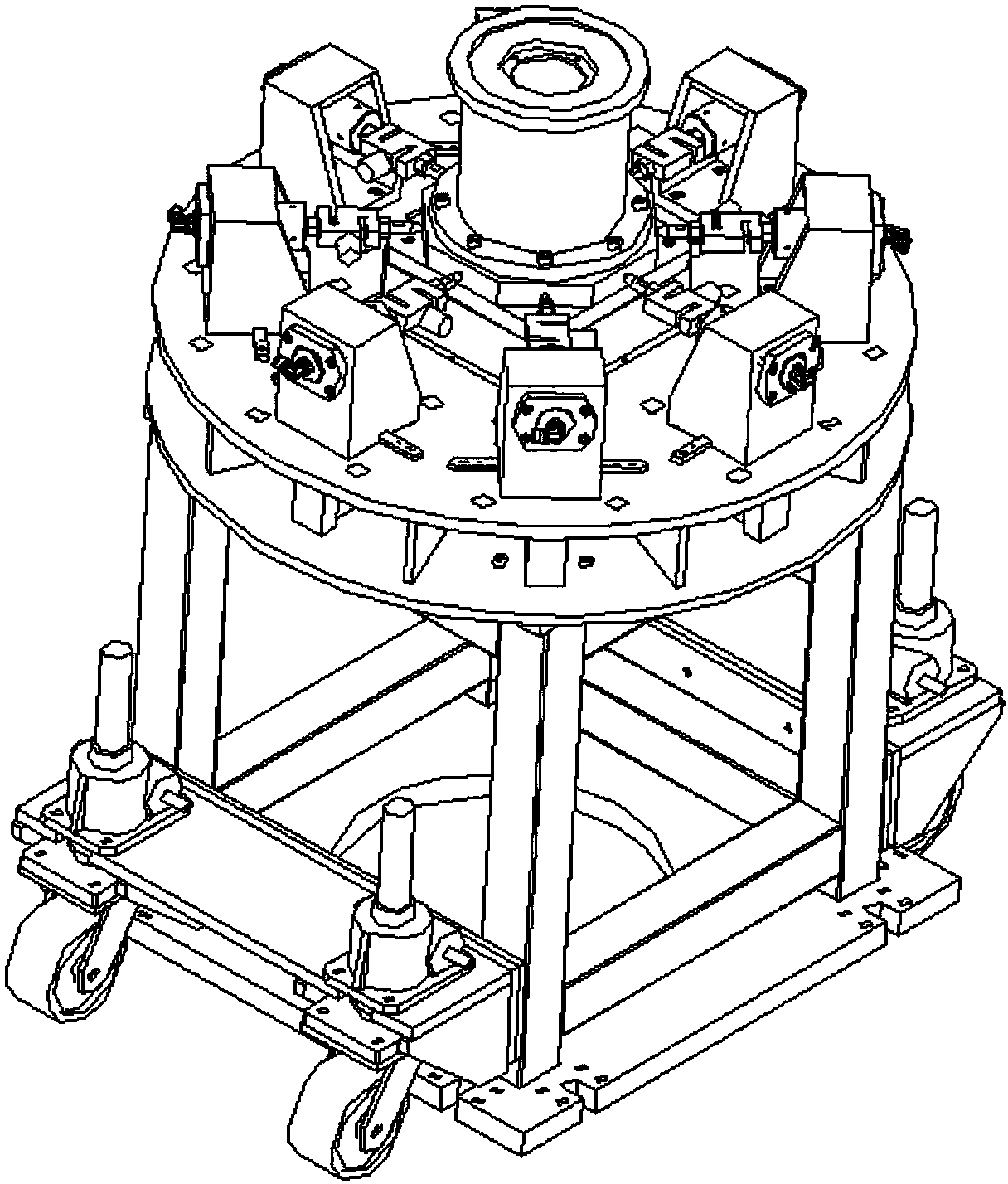

[0029] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

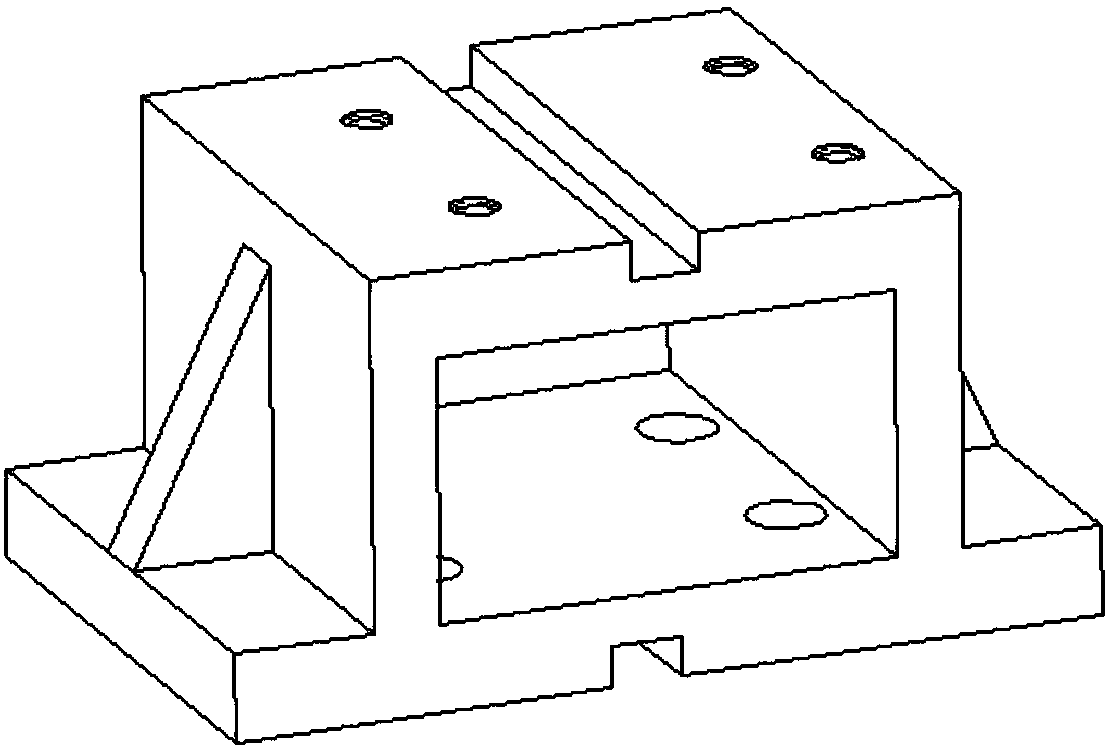

[0030] After the main hydraulic power system 5 is connected to the hydraulic oil, the rear center tie rod 8 will drive the standard force sensor 10 and the front end center tie rod 11 to pull down under the drive of the hydraulic oil, and through the loading nut 13 connected to the front end center tie rod 11 Finally, the force is applied to the calibration plate 12 to realize the simulated loading of the main force in the X direction; the lateral force in the Y direction is applied to the sides of the calibration plate through the lateral loading device 3 after the hydraulic oil is connected laterally. To realize the simulated loading in the Y direction. The same goes for the Z direction. Five sets of threaded holes with the same spacing and the same size are arranged on each station on the upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com