A grating precise alignment bonding method and device thereof

A bonding device and grating technology, applied in optics, optical components, instruments, etc., can solve the problems of glue overflow, inability to realize automation, and low degree of automation, and achieve high alignment accuracy and avoid electrical damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

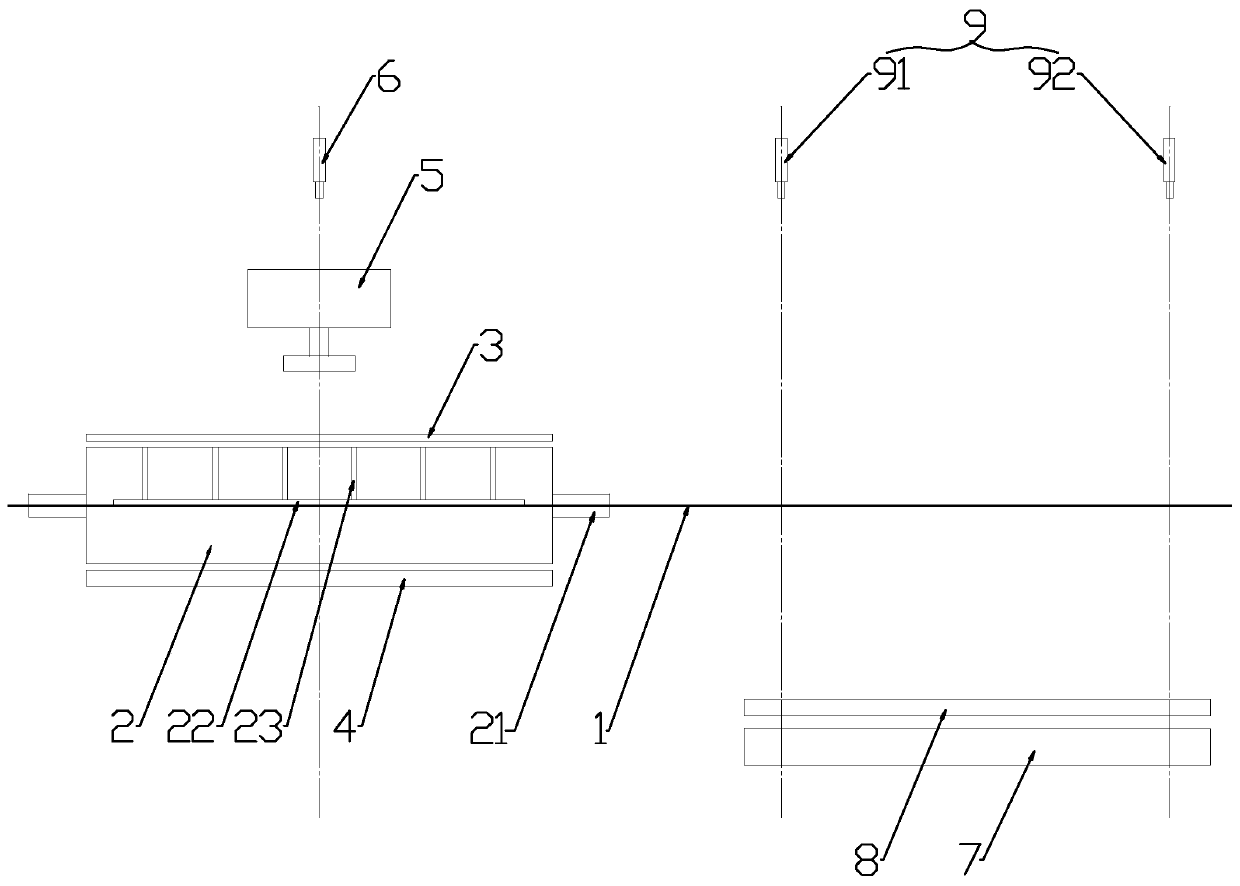

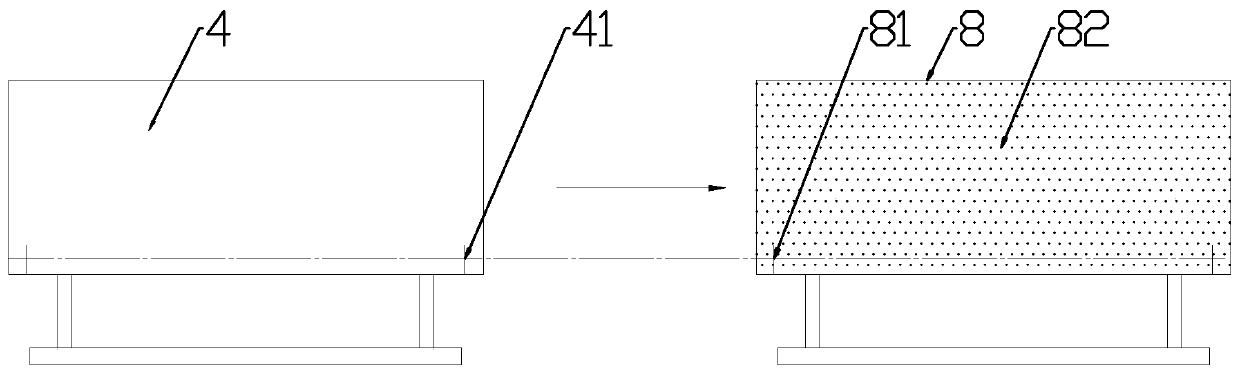

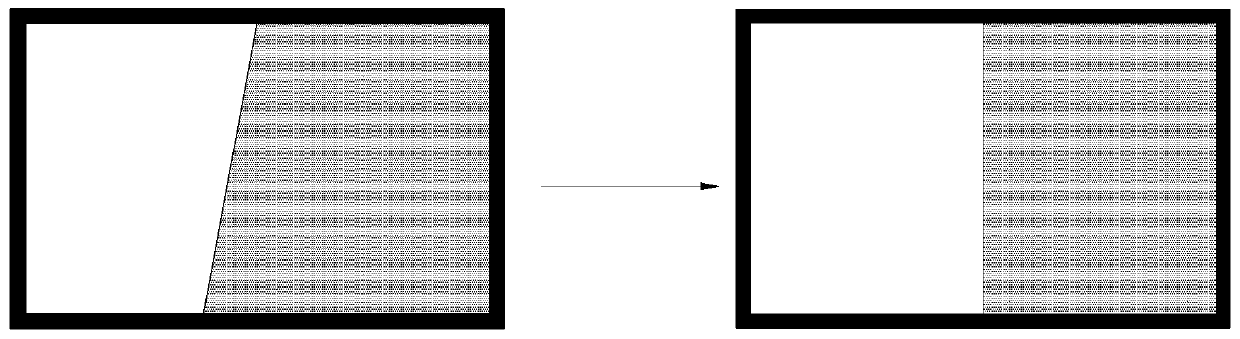

[0038] In this embodiment, the precise alignment and bonding device of the grating is combined with figure 1 , including track 1, transparent vacuum adsorption platform 2, reference screen 4, test chart observation display screen 5, test chart intake camera 6, three-axis alignment platform 7, screen to be bonded 8 and Mark recognition CCD9, on the reference screen 4 Set the test chart, the transparent vacuum adsorption platform 2 is installed on the track 1, and moves left and right along the track 1; the rotating shaft 21 is set on the transparent vacuum adsorption platform 2, and the rotating shaft 21 drives the transparent vacuum adsorption platform 2 to rotate around its horizontal axis, to be bonded The film 3 is adsorbed on the top of the transparent vacuum adsorption platform 2, and the test pattern observation display screen 5 and the test pattern intake camera 6 used in conjunction with the test pattern observation display screen 5 are set above the film 3 to be bonded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com