Self-locking fast expanding sleeve pull-out device for connection of rocker arm device and grinding roll device

A self-locking and expanding sleeve technology, used in fixtures, mechanical equipment, grain processing, etc., can solve the problems of single structure, large impact load, aggravated economic losses, etc., to reduce safety risks, improve efficiency, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

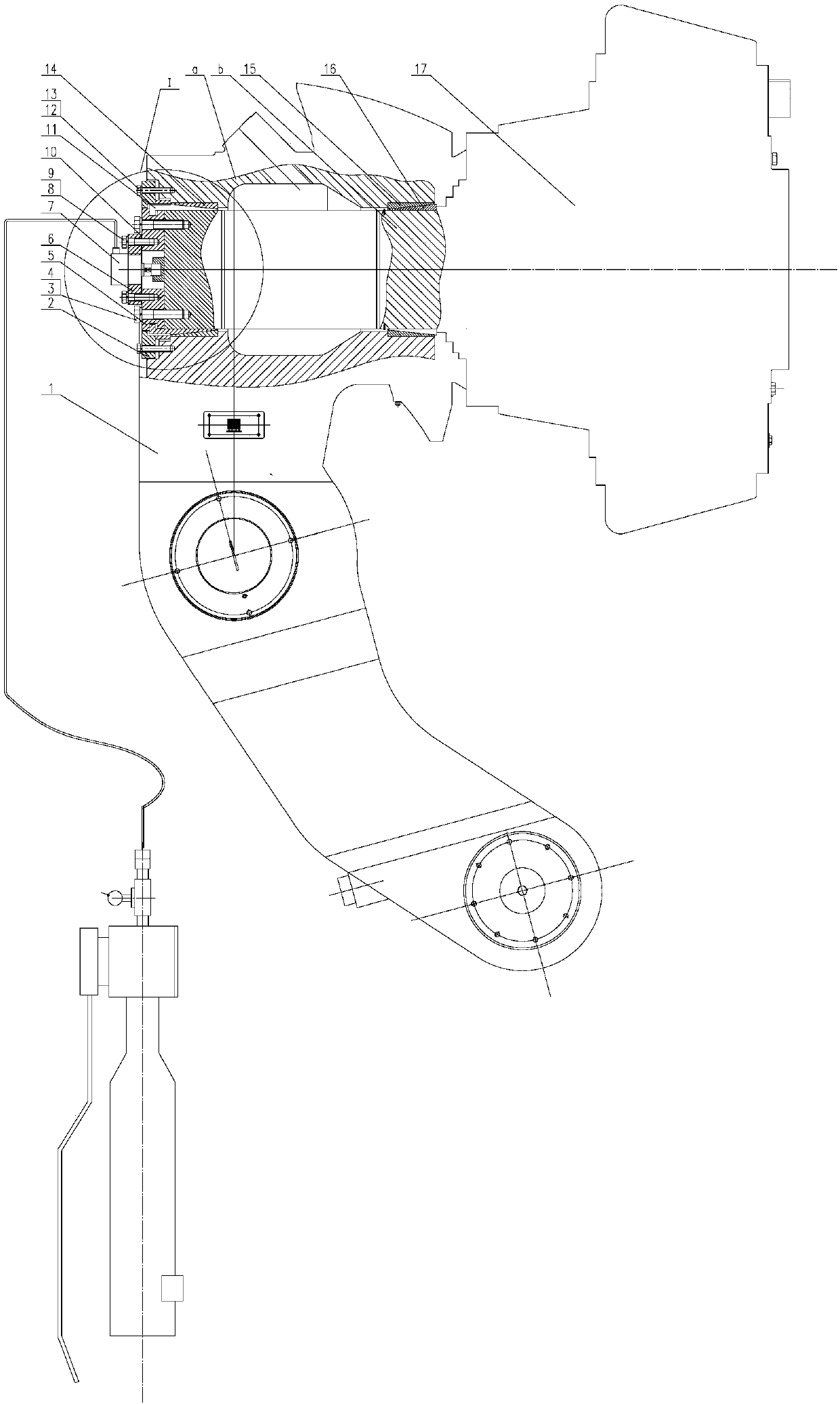

[0030] see Figure 1 to Figure 11 , a self-locking quick-lifting expansion sleeve device for connecting the rocker arm device and the grinding roller device,

[0031] The rocker device 1 includes an upper rocker a, and the grinding roller device 17 includes a grinding roller shaft b;

[0032] The upper rocker arm a is a hollow tubular structure, the grinding roller shaft b is inserted from the front hole of the upper rocker arm a, and reaches the rear end hole of the upper rocker arm a; include:

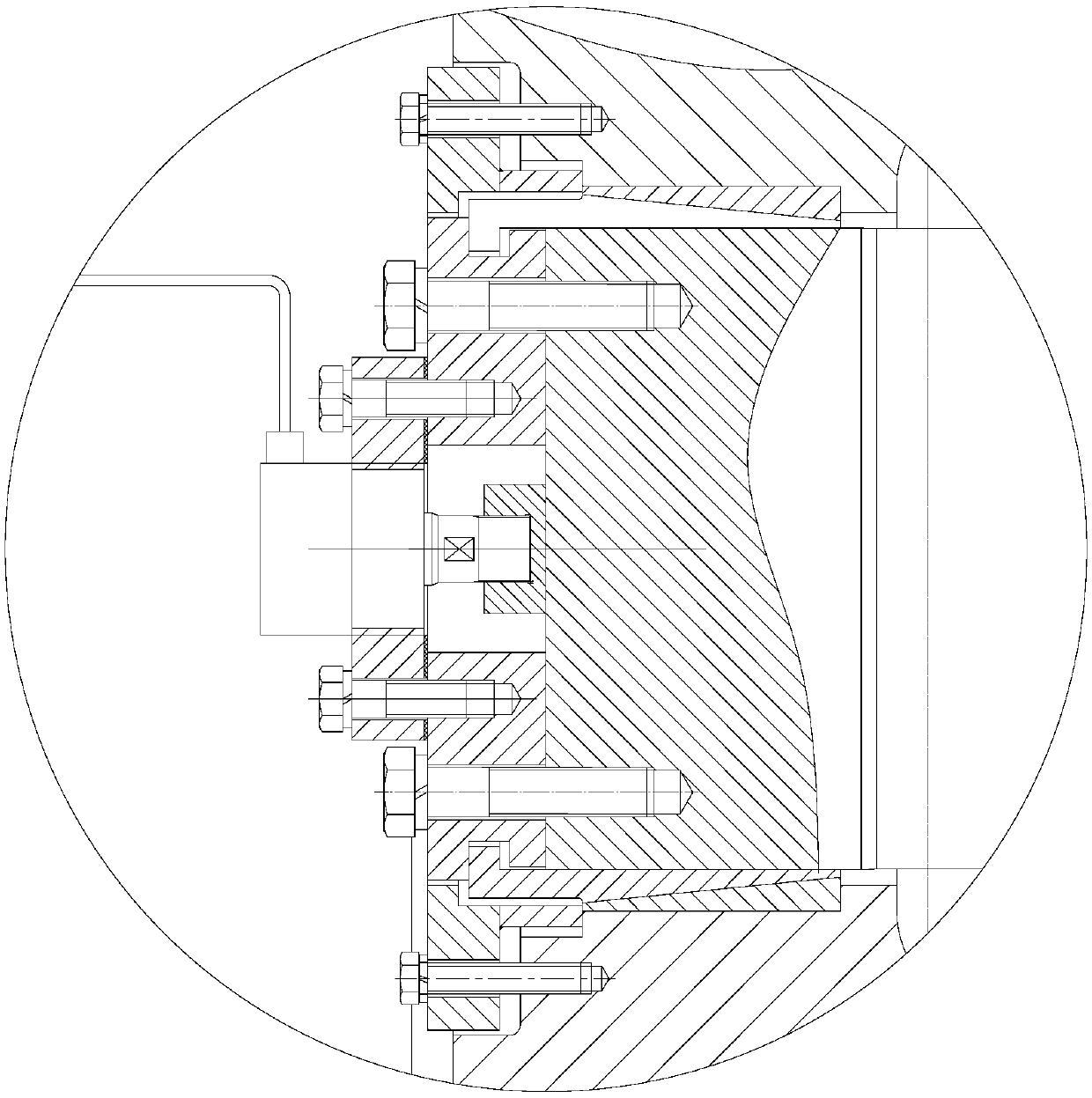

[0033] The front member located at the position of the front hole; the front member includes the front external expansion sleeve 15 and the front internal expansion sleeve 16 located between the outer wall of the grinding roller shaft b and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com