Efficient injection molding equipment

An injection molding equipment and high-efficiency technology, applied in the field of high-efficiency injection molding equipment, can solve the problems of long injection mold time, low manufacturing efficiency, limited hot melt speed, etc., to reduce the time for filling the mold cavity, improve the feeding speed and heat. The effect of reducing melting speed and production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

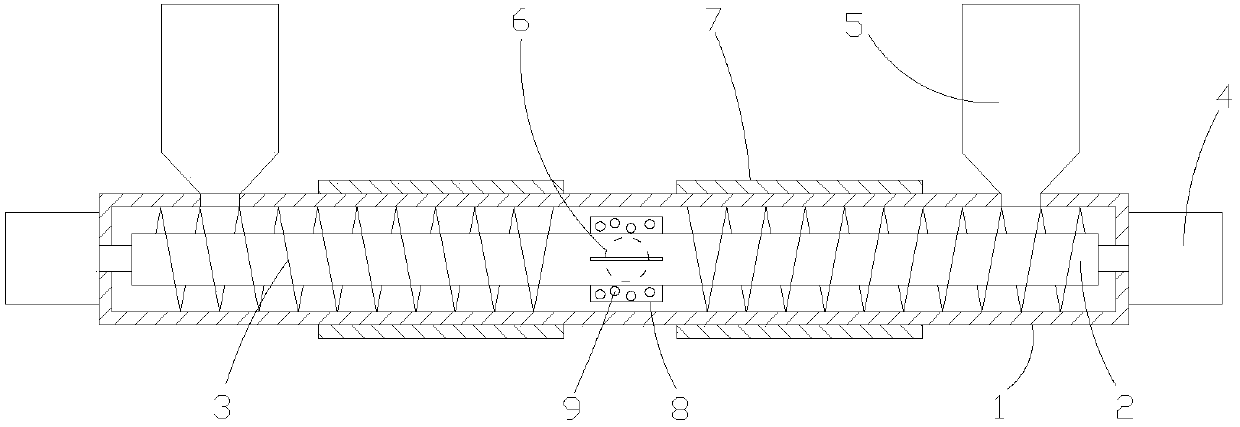

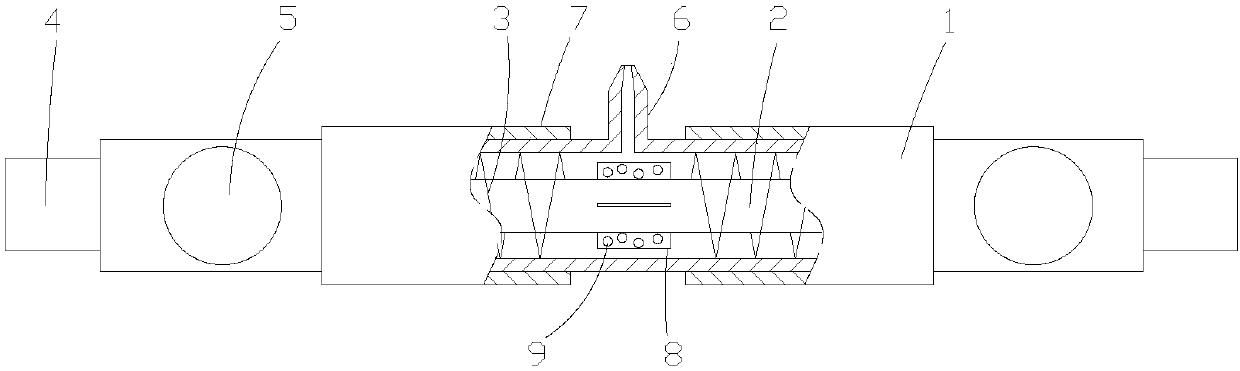

[0016] Example. A high-efficiency injection molding equipment, such as figure 1 and figure 2 As shown, the material barrel 1 is included, and the inside of the material barrel 1 is provided with a screw 2, and the two ends of the screw 2 are respectively provided with spiral propellers 3 with opposite rotation directions; Pass through the barrel 1 and connect with the screw 2; both ends of the barrel 1 are provided with a hopper 5, the middle of the barrel 1 is provided with a nozzle 6, and both sides of the nozzle 6 are equipped with a heating device 7 set on the barrel 1 .

[0017] There are two variable speed motors 4, which are respectively arranged at the two ends of the barrel 1, and the output ends of the two variable speed motors 4 are connected with the two ends of the screw rod 2 respe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap