Motor-started pressure-relief buffer device for high pressure cleaning machine

A high-pressure cleaner and buffer device technology, which is applied to valve devices, valve operation/release devices, mechanical equipment, etc., can solve the problems of shortening the service life of the motor, sudden increase in the load of the motor, and damage to the motor, so as to prolong the service life , the effect of efficient startup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

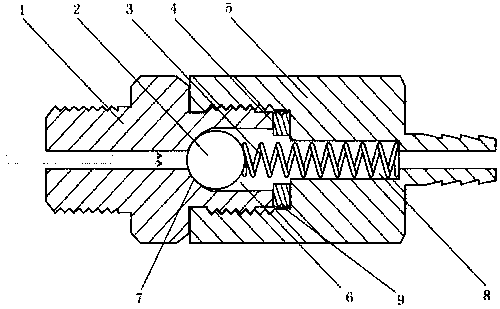

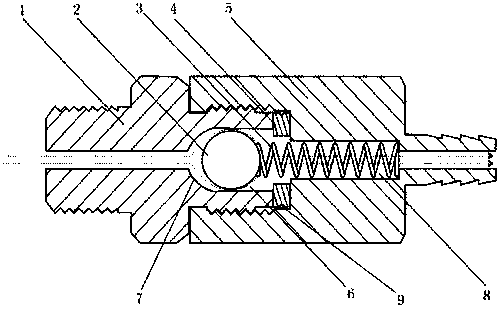

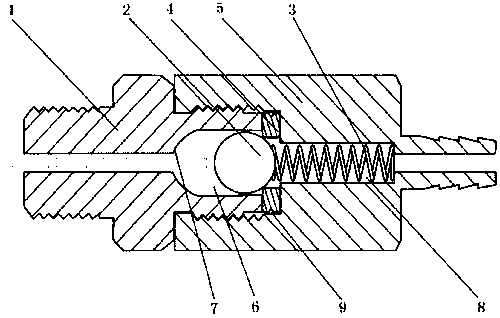

[0014] The present invention is composed of a water inlet valve body 1, a valve bead 2, a spring 3, an annular valve seat 4 and a water outlet valve body 5. The water inlet valve body 1 is provided with a cylindrical valve bead chamber 6, and the valve bead chamber 6 One end is a hemispherical valve 7, the outlet valve body 5 is provided with a cylindrical spring housing chamber 8, the annular valve seat 4 is placed inside the outlet valve body 5, the inlet valve body 1 is screwed on the outlet valve body 5, and the The annular valve seat 4 is tight, the spring 3 passes through the annular valve seat 4 and is placed in the cylindrical spring housing chamber 8 in the outlet valve body 5, the valve ball 2 is placed in the cylindrical valve bead chamber 6, and the spring 3 holds the valve ball 2 tops are pressed on the hemispherical valve 7.

[0015]...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap