Apparatus and method for separating shale particles of different particle sizes

A particle separation and mud shale technology, applied in particle and sedimentation analysis, measuring device, particle size analysis, etc., can solve the problems of limited mortar volume, limited amount of grinding samples, labor-intensive and other problems, achieve rapid physical decomposition, avoid grinding Fragmentation process, overcoming destruction and effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings.

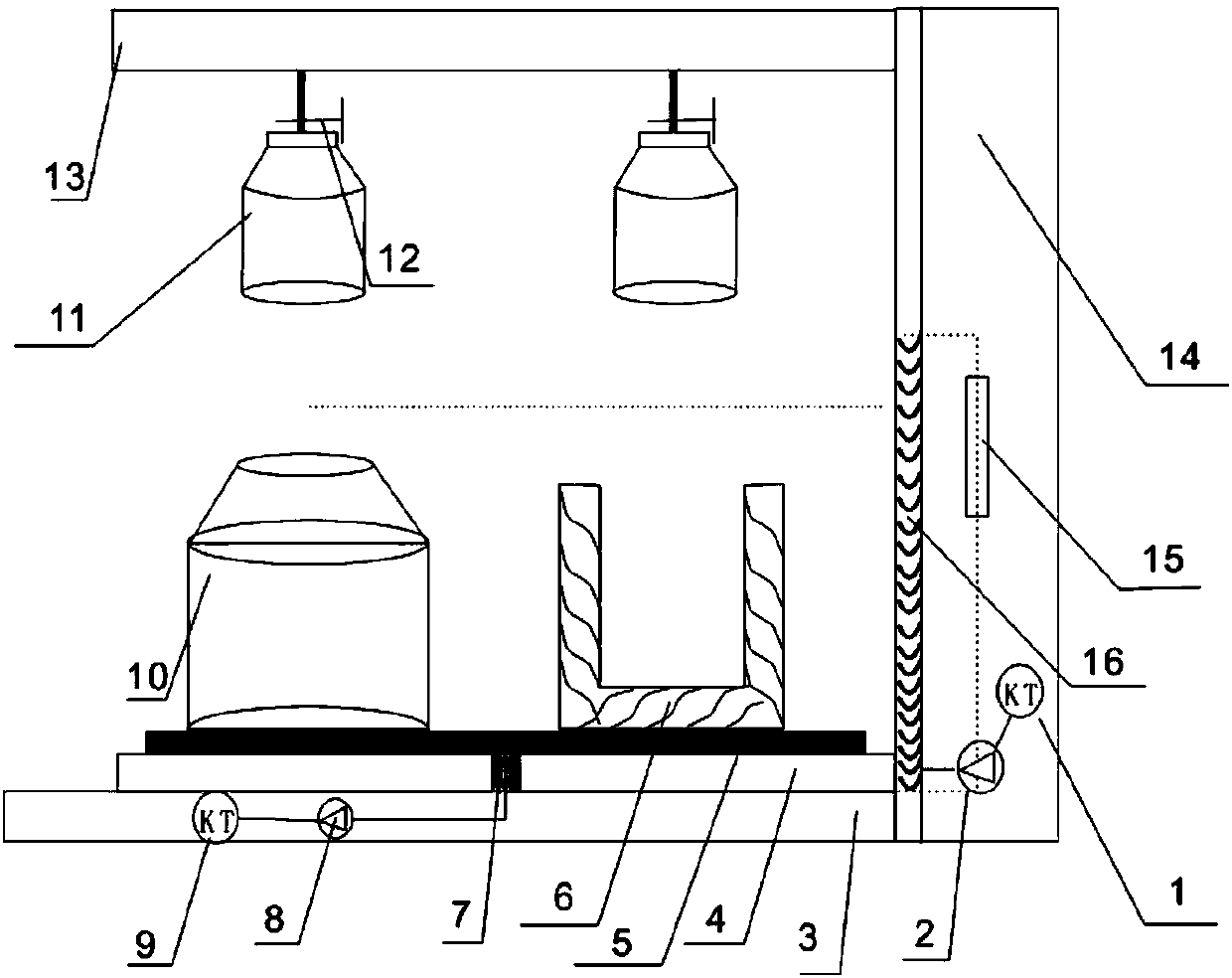

[0028] figure 1 It is a schematic diagram of the structure of a device for separating particles of different sizes of shale, a device for separating particles of different sizes of shale, including a vertical beam 14 equipped with a horizontal hanging rod 13, and a set of matching liquid nitrogen bottles. 10 and electromagnetic heater 6, PTFE bottle 11 and base 3;

[0029] The horizontal hanging rod 13 is arranged at the top of the vertical beam column 14 and is perpendicular to the vertical beam column 14, the horizontal hanging rod 13 is provided with a fixed buckle 12, and the base 3 is located at the bottom end of the vertical beam column 14 and is perpendicular to the vertical beam. Column 14, the base 3 is provided with a mobile table 4, the mobile table 4 is provided with a rotary table 5, the liquid nitrogen bottle 10 and the electromagnetic heater 6 are placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com