Fuel cell and fuel cell stack

A fuel cell stack and membrane electrode technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as suboptimal volume power density, non-uniform distribution of reactants, slow dynamic response, etc., to achieve good fuel cell efficiency, Good uniform distribution and low pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

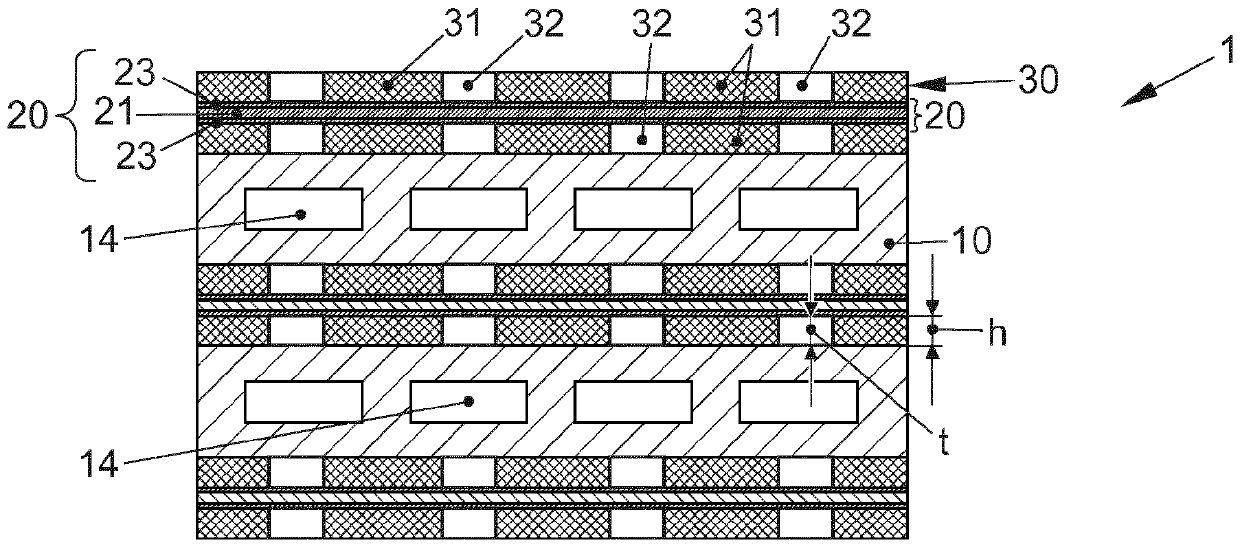

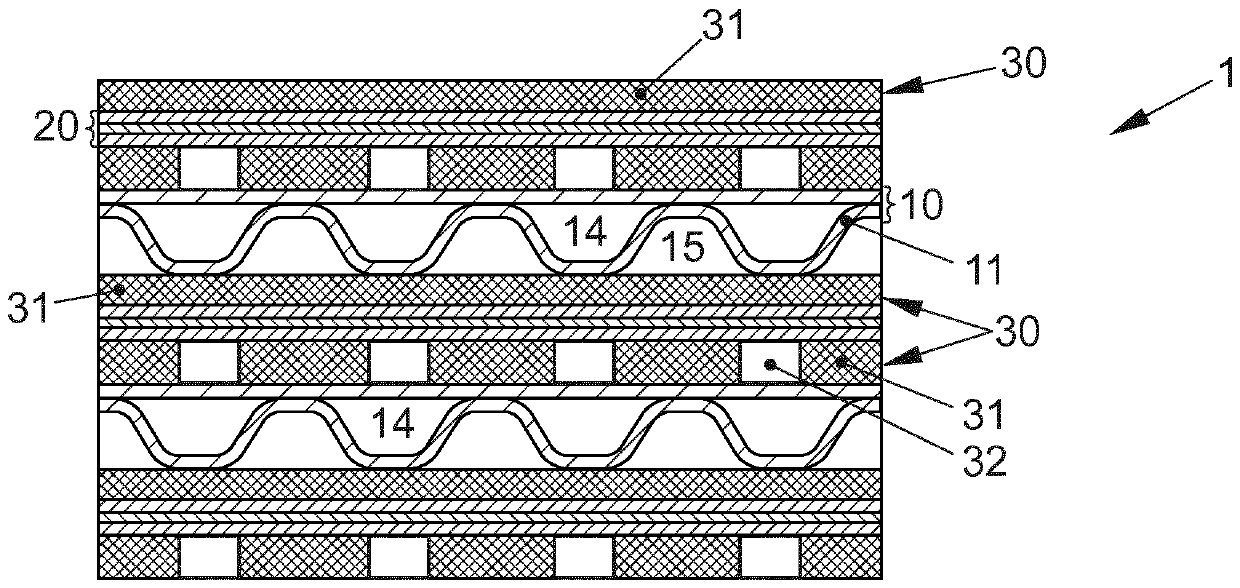

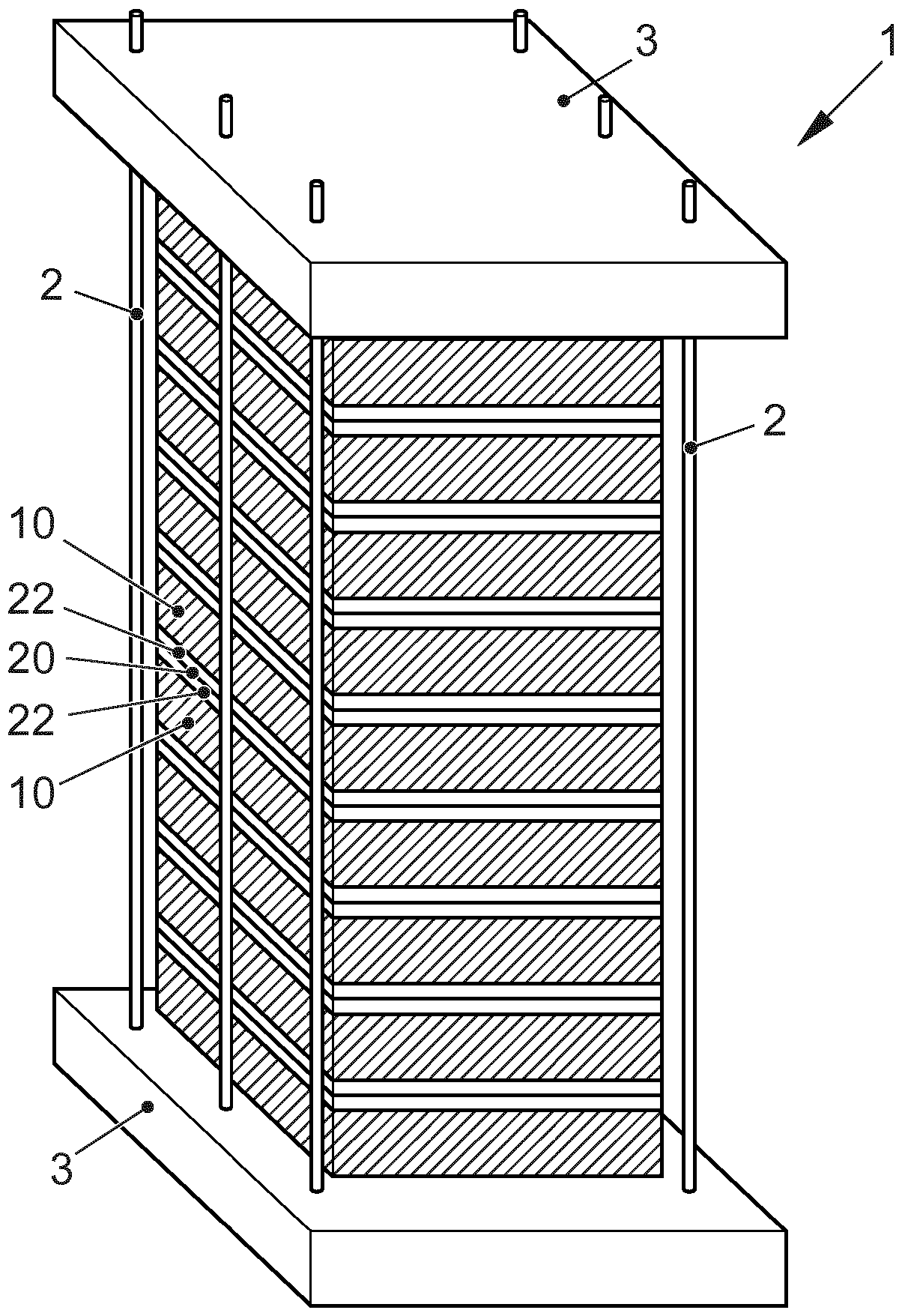

[0042] figure 1 A fuel cell stack is shown in a strongly schematic illustration. The fuel cell stack 1 comprises two end plates 3 between which a plurality of stacked stack elements comprising bipolar plates 10 and membrane electrode units 20 are arranged. The bipolar plates 10 are alternately stacked with the membrane electrode units 20 . The membrane electrode unit 20 includes a membrane and electrodes connected on both sides of the membrane, ie, an anode and a cathode (not shown), respectively. In addition, the membrane electrode unit 20 can have a gas diffusion layer 22 abutting the electrodes. A sealing element is arranged between the bipolar plate 10 and the membrane electrode unit 20 , which seals the anode chamber and the cathode chamber gas-tight to the outside (not shown). The fuel cell stack 1 is pressed together between the end plates 3 by means of tensioning elements 2 , for example tie rods or clamping plates.

[0043] exist figure 1 In , only the narrow sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com