Multi-cylinder driving caterpillar type low speed and heavy loading device walking mechanism

A low-speed, heavy-duty, walking mechanism technology, applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of high cost, difficult maintenance, unsuitable for long-distance walking, etc., and achieve the effect of convenient maintenance and simple structure of the oil cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

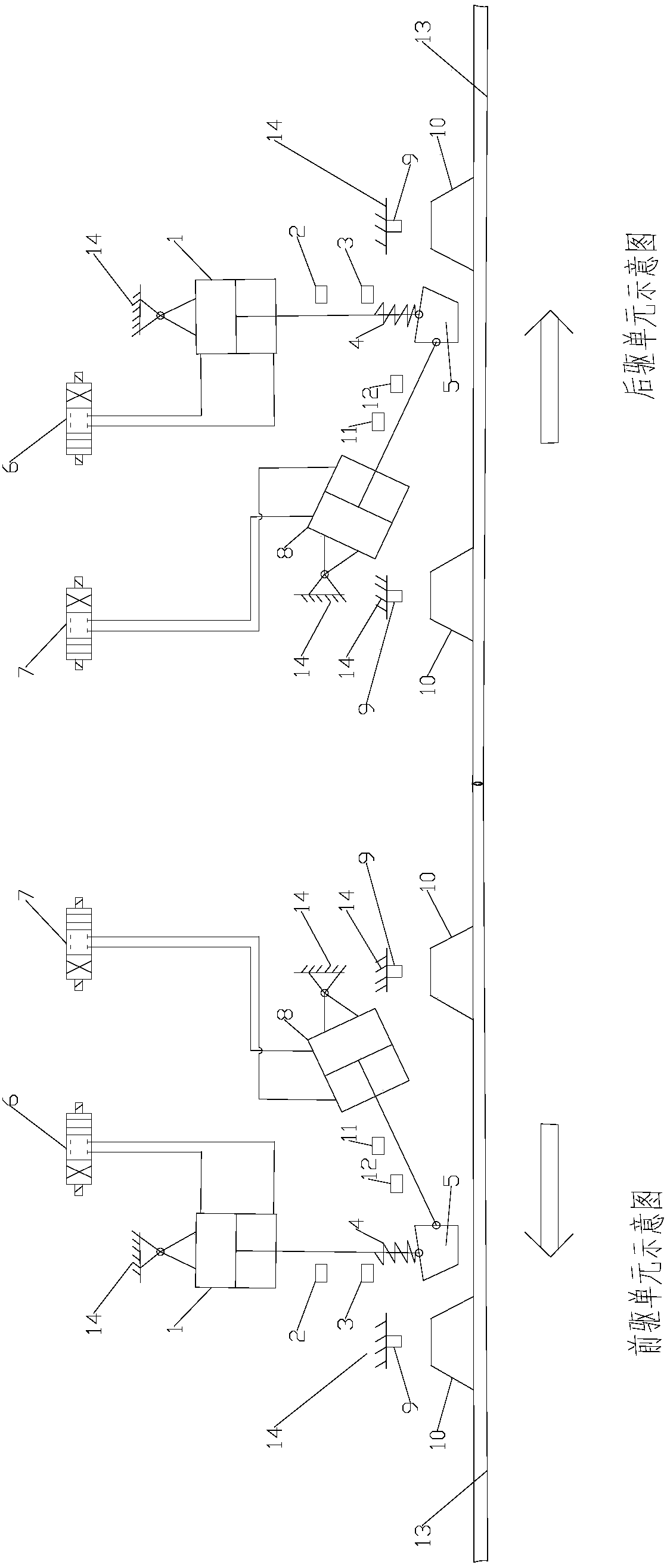

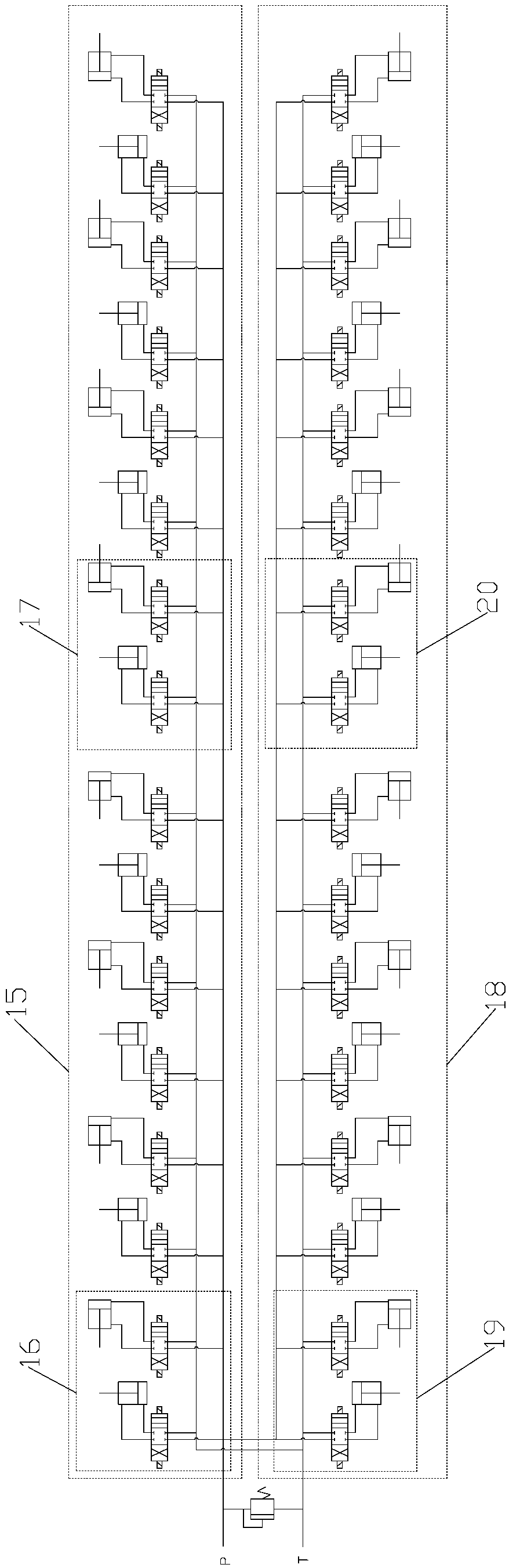

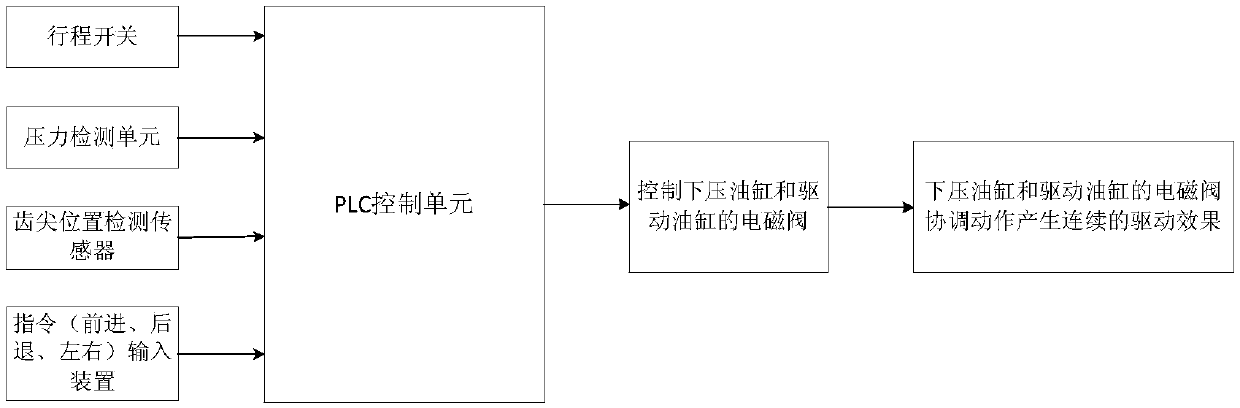

[0027] A multi-cylinder driven crawler-type low-speed heavy-duty equipment traveling mechanism, including a control unit, a sensor for detecting the position of the crawler teeth, a forward drive system and a reverse drive system arranged in each track frame to drive the crawler teeth, the forward drive system Both the drive system and the reverse drive system include two sets of drive devices with complementary strokes, and each set of drive devices includes at least one drive unit; each drive unit includes a drive head for driving the crawler teeth, a press cylinder for controlling the up and down movement of the drive head, and a drive unit for controlling the drive. The head moves back and forth to push the driving cylinder of the crawler teeth, and the limit switch for detecting the position of the piston rod of the pressing cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com