Coincidence degree correcting device for bending machine with side position structure

A technology of coincidence degree and bending machine, which is applied in the field of bending machine and can solve the problems such as the inability to express the inspection effect intuitively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

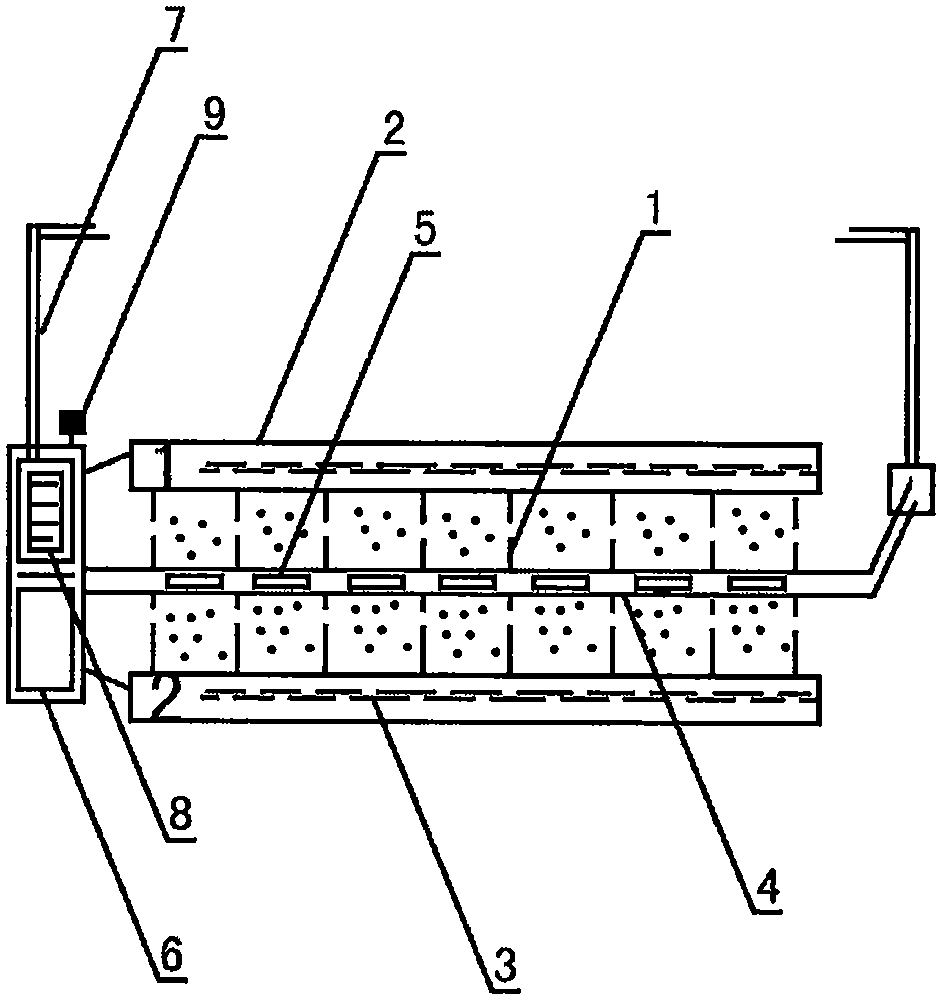

[0012] Embodiment: as shown in the accompanying drawing. The coincidence degree correction device of bending machine with side structure includes a frame body (1). The frame body (1) stands laterally on the lower end of the machine body and is designed to be the same length as the die. The middle part is equipped with a multi-layer detection structure including two concave grooves. Device (2), coincidence degree sensing device (3), protective cover device (4), firmness detection device (5), and display device (6) are located on the left side of the frame body. When the body is empty and starts, the support swing arm ( 7) Insert the detection parts of the frame body (1) into the middle of the upper and lower molds as a whole, and transmit the corresponding detection data to the central control device (8), analyze and compare the coincidence degree and firmness of the molds, and make corrections in conjunction with the main control parts of the body.

[0013] The coincidence deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com