Comprehensive experiment device for process unit equipment

A technology of comprehensive equipment and experimental devices, applied in educational appliances, instruments, teaching models, etc., can solve problems such as disadvantage of students' independent thinking and innovation ability, large area, low integration, etc., to achieve rich functions, compact structure, Well-planned effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

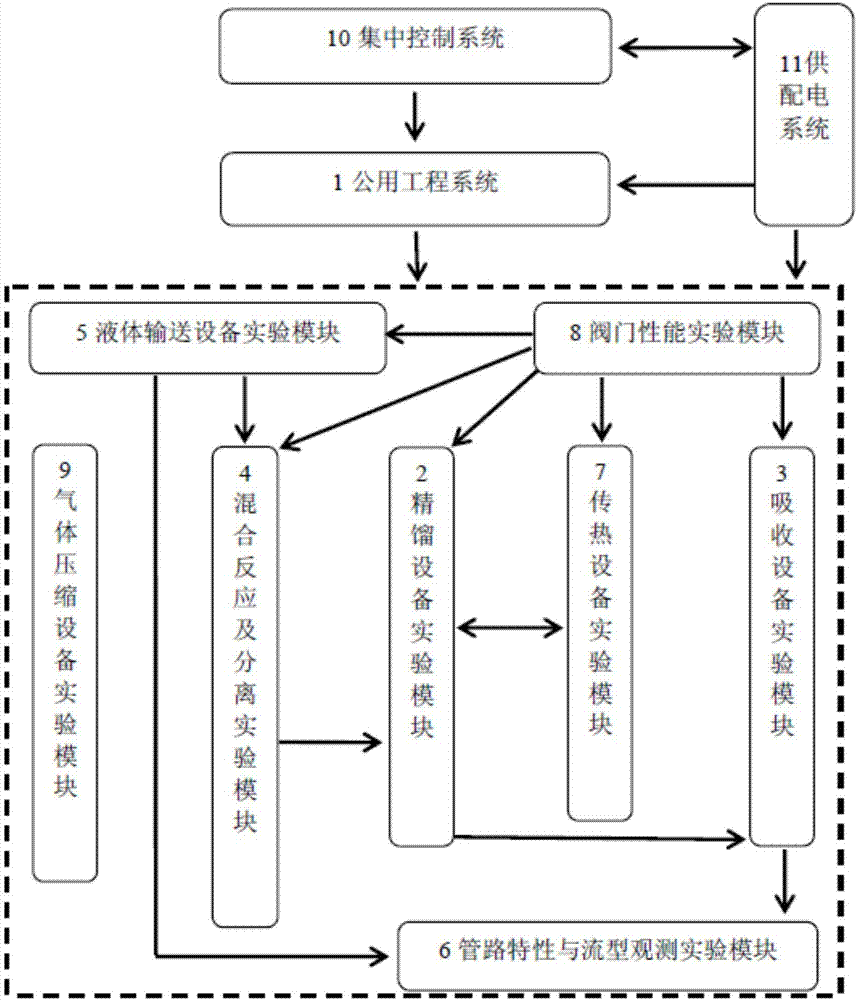

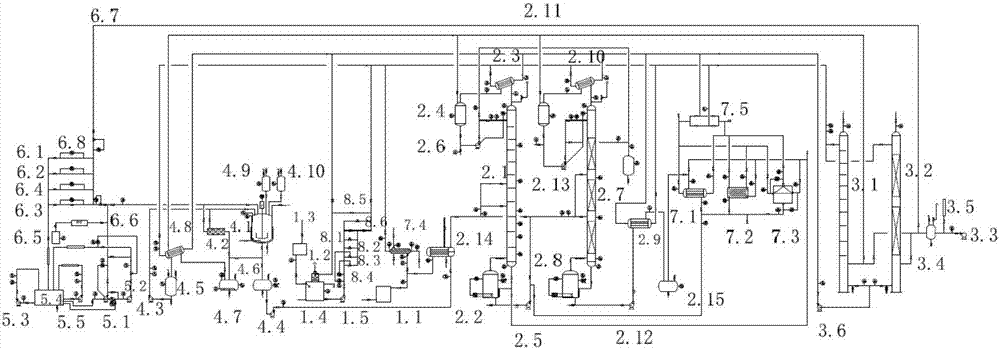

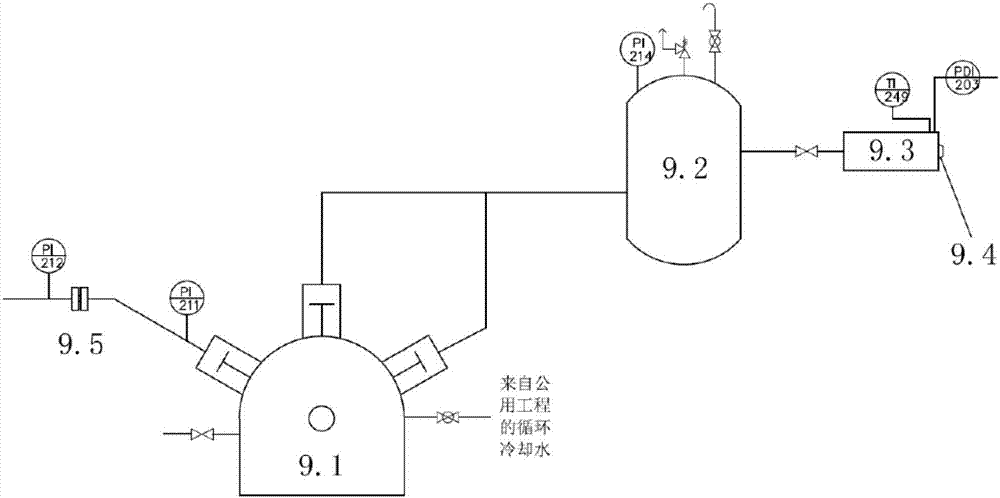

[0062] Such as figure 1 , figure 2 , image 3 As shown, the main components and functions are as follows:

[0063] The utility system 1 can provide normal temperature demineralized water and heating steam for the whole experimental system and each experimental module therein. The utility system 1 consists of a steam generator 1.1, a cooling tower 1.2, a set of water softening equipment 1.3, a softening water tank 1.4, a centrifugal water pump 1.5 and necessary pipelines, valves, instruments and control components. The steam generator 1.1 can provide thermal energy for the experimental module 2 of rectification equipment, the experimental module 4 of mixing reaction and separation equipment, and the experimental module 7 of heat transfer equipment. The cooling tower 1.2 can reduce the temperature of the circulating return water and make it return to normal temperature. Water softening equipment 1.3 can soften tap water and improve the water quality of circulating water for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com