Improved self-pretightening rotary shaft assembly

A pre-tightening, improved technology, applied to building components, door/window protection devices, windows/doors, etc., can solve problems such as inability to fully absorb impacts, bumps, limited buffer sleeve thickness, and complicated assembly processes, etc., to achieve structural Simplicity, improved production efficiency, and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

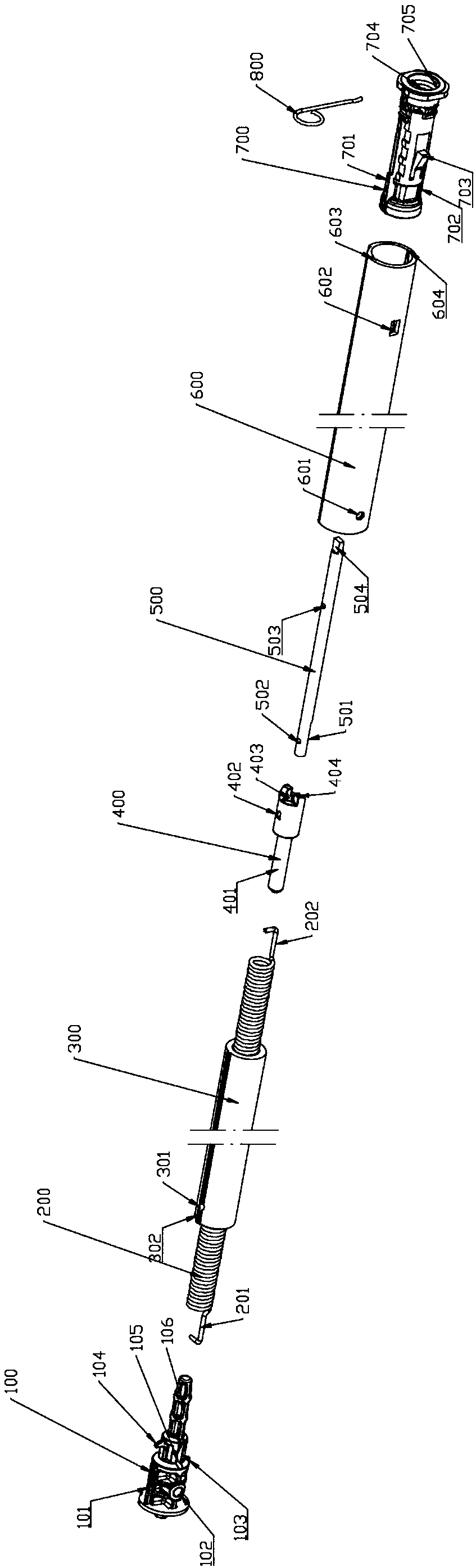

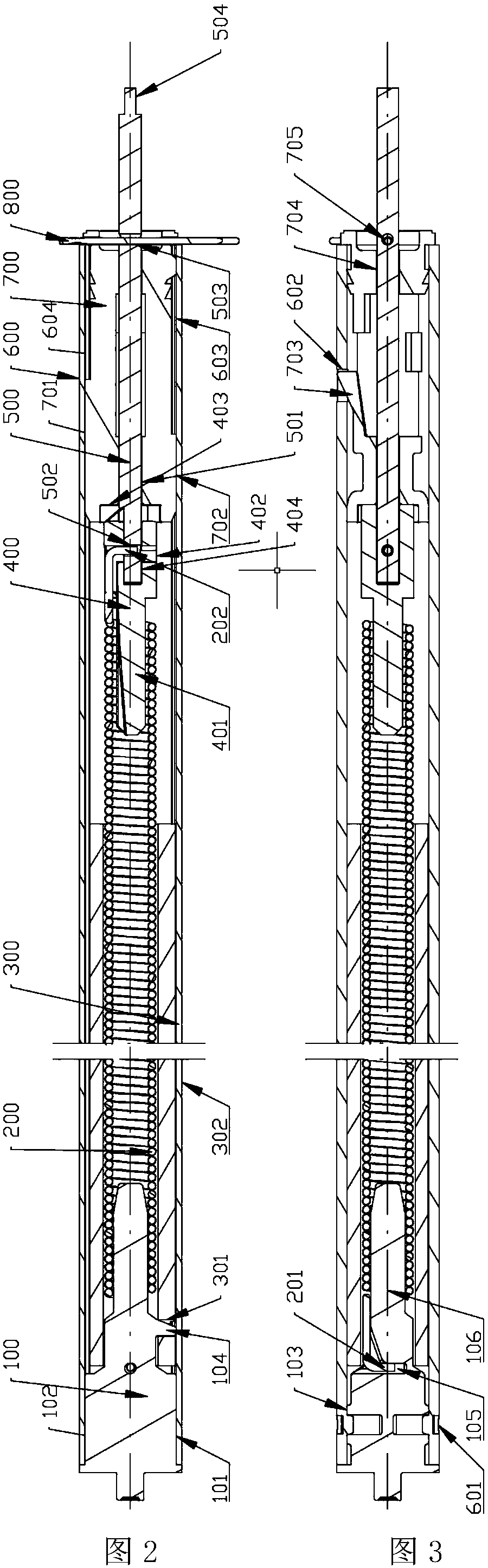

[0037] see Figure 1 to Figure 3 , an improved self-pretightening shaft assembly shown in the figure, including a right support 100 (first support), a spring 200, a silencer tube 300, a left support limit sleeve 400, a fixed shaft 500, an aluminum tube 600, left support 700 (first support), positioning pin 800.

[0038] The aluminum pipe 600 in this implementation case adopts 6063-T5 aluminum extruded pipe, the right support 100, the left support limit sleeve 400, and the left support 700 are plastic parts; the silencer pipe 300 is a rubber part; the spring 200, the positioning pin 800 is a wound spring part, and the fixed shaft 500 is a machined steel part.

[0039]The inner tube wall of the aluminum tube 600 is provided with limiting grooves 603 and 604 extending axially and radially recessed on the surface. The limiting groove 603 is the first limiting groove, and the limiting groove 604 is the second limiting groove. In addition, an anti-retraction riveting point 601 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com