Thickness experimental device and application method thereof for variable boundary layer during cavity flow wind tunnel test research

A technology of boundary layer thickness and wind tunnel test, applied in the field of experimental fluid mechanics, it can solve the problems of large change of boundary layer parameters, increase of boundary layer, not well solved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

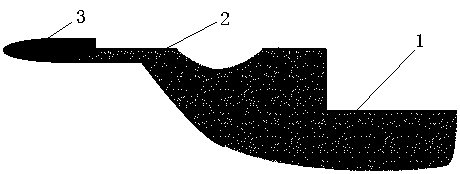

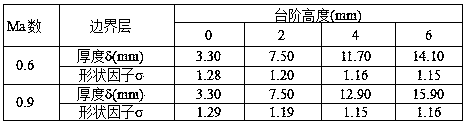

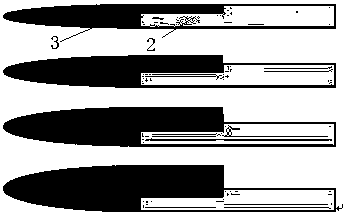

[0030] The test model is a C201 cavity standard mold with a total length of 514mm and a width of 320mm. Among them, the cavity is 200mm long, 66.7mm wide and 33.3mm deep. Before the cavity, there is a flat plate with a length of about 200 mm for the development of a turbulent boundary layer. In the experiment, step blocks of four different specifications such as 0mm, 2mm, 4mm, and 6mm were added to the front of the plate to change the thickness of the turbulent boundary layer at the entrance of the cavity, so as to study the influence of the boundary layer thickness on the unsteady flow of the cavity.

[0031] According to the characteristics of the back-step flow, the velocity profile of the flow in the separation zone and the recovery zone downstream of the step is an irregular velocity profile. In order to fully develop the flow in the boundary layer, it is necessary to set a sufficiently long recovery zone. The length of the recovery area is about 20 times the height of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com