Sow precision feeding system

A precision and sow technology, which is applied in the field of sow precision feeding system, can solve the problems of feed waste, labor cost and feed waste in pig farms, so as to improve the level of automation and refinement, which is conducive to healthy growth and Breeding and beneficial to the effect of scientific management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

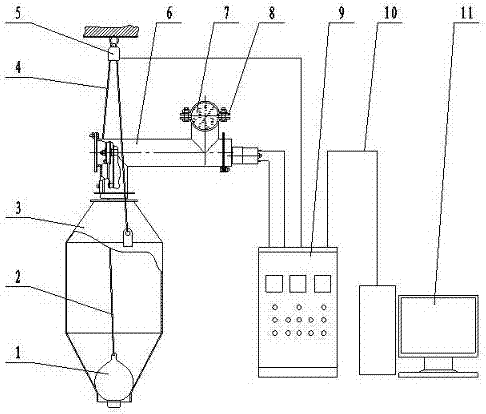

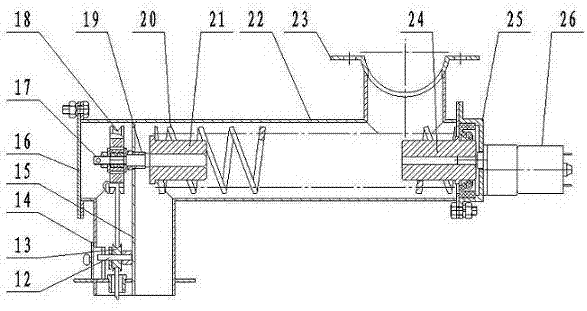

[0011] The present invention will be further described below in conjunction with the accompanying drawings: the precision feeding system for sows consists of a sealing ball (1), a pull wire (2), a precision bucket (3), a hanging rope (4), an electronic weighing sensor (5), and a feeder. Feeder (6), automatic material line feeding pipe (7), upper semicircle clamp (8), electrical control system (9), wires (10), computer (11), etc., wherein the feeder (6) is It consists of optical shaft (12), guide wheel (13), threading door (14), discharge partition (15), end cover (16), auger top shaft (17), ratchet assembly (18), sliding shaft Sleeve (19), auger (20), transition shaft hub (21), feed pipe welding (22), lower semicircle clip (23), drive shaft hub (24), motor flange (25), DC deceleration Composition such as motor (26). The precision bucket (3) is a round spindle-shaped container with a circular inlet on the top and a circular outlet on the bottom. The hanging ropes (4) are symme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap