Packing box capable of preventing zebra stripes of non-woven fabric rolls

A technology of zebra pattern and packing box, which is applied in the direction of packaging, transportation and packaging, bottle/can parts, etc., can solve the problems of non-woven fabric roll damage, non-woven fabric roll zebra pattern, etc., and reduce the probability of damage , short packing length and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

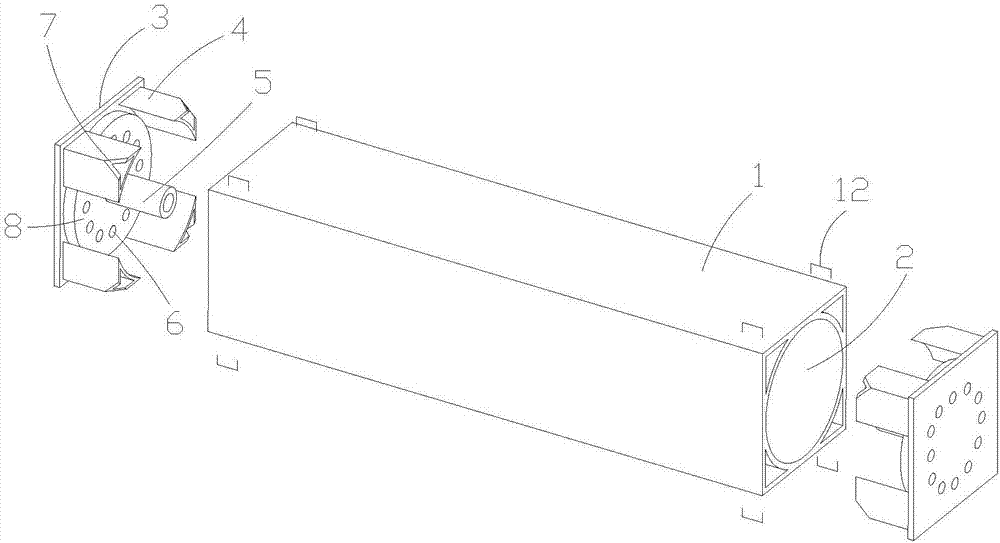

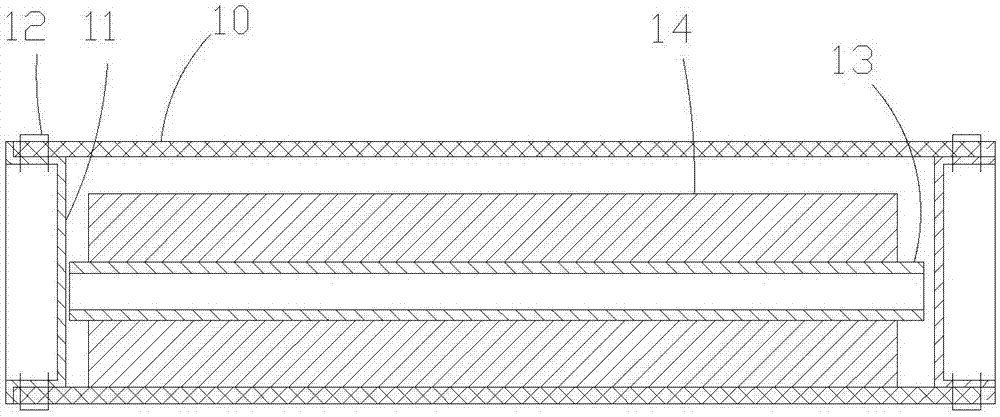

[0018] Example. A packaging box that avoids zebra patterns from non-woven fabric rolls, such as figure 1 As shown, it includes a paper tube and end caps located at both ends of the paper tube; the paper tube includes a square tube 1 and a round tube 2 inside the square tube 1, and the square tube 1 is bonded to the round tube 2; the end cap includes The square cover plate 3 is provided with pins 4 at the four corners of the cover plate 3 facing the paper tube, and the center of the cover plate 3 is provided with a hanging rod 5 protruding into the circular tube 2 . Both the square tube 1 and the round tube 2 are made of cardboard.

[0019] The cover plate 3 is provided with ventilation holes 6 , and the ventilation holes 6 are circumferentially distributed on the outside of the hanging rod 5 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com