Rust-proof nut

A technology of nuts and rings, applied in the field of anti-rust nuts, can solve problems such as waste of working time, increased burden on users, heavy rakes, etc., and achieve the effects of avoiding deformation damage, avoiding dead connections, and preventing rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

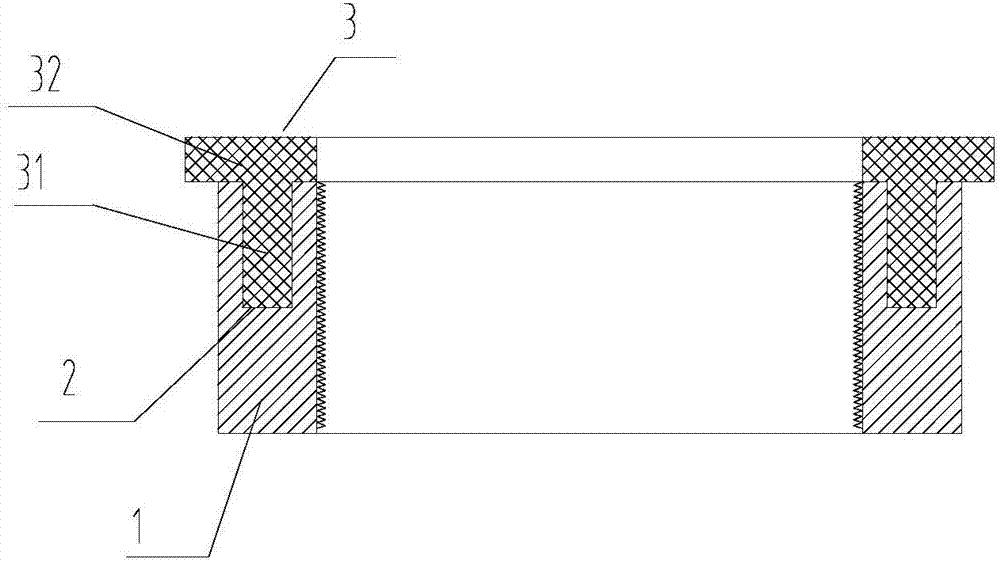

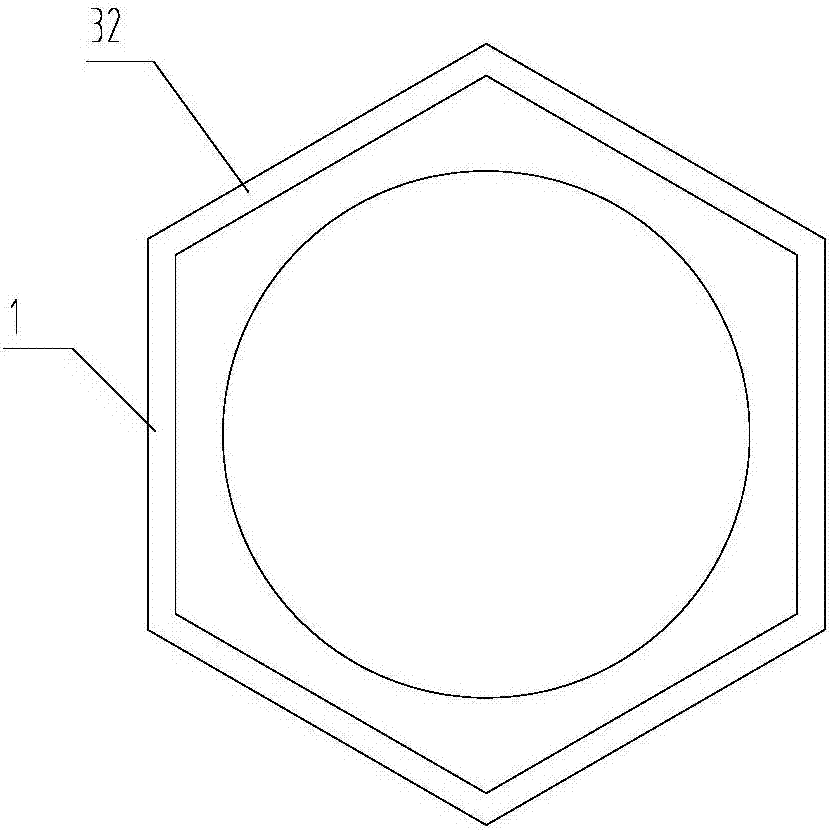

[0014] refer to figure 1 , figure 2 , a rust-proof nut proposed by the present invention, one end of the nut 1 is provided with an annular groove 2, and an annular gasket 3 is installed in the annular groove 2. The ring pad 3 is composed of a first ring part 31 and a second ring part 32 integrally formed. The first ring part 31 is inserted into the ring groove 2 to fix the ring pad 3 , and the second ring part 32 coaxially covers the first ring part 31 on the end surface of the nut 1 . The diameter of the inner ring of the second ring part 32 is equal to the diameter of the inner ring of the nut 1 , so as to prevent the ring pad 3 from blocking the operation of the nut 1 , and the outer ring of the second ring part 32 extends out of the end surface of the nut 1 . In this way, when the nut 1 is in working condition, when the screw or other external thread structures are locked by rotating the nut 1, the nut 1 abuts against the fixed structure through the ring pad 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com