Self-adjustable face-to-face reciprocating type friction testing device and testing method thereof

A test device, reciprocating technology, applied in the direction of measuring devices, wear resistance testing, instruments, etc., can solve the problems of incomplete contact of the contact surface, friction signal can not truly reflect the characteristics, can not guarantee the complete contact of the friction surface, etc., to achieve Increased authenticity and accuracy, simple structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments and examples of the present invention will be described in detail below in conjunction with the accompanying drawings. The described specific embodiments are only used to explain the present invention, and are not intended to limit the specific embodiments of the present invention.

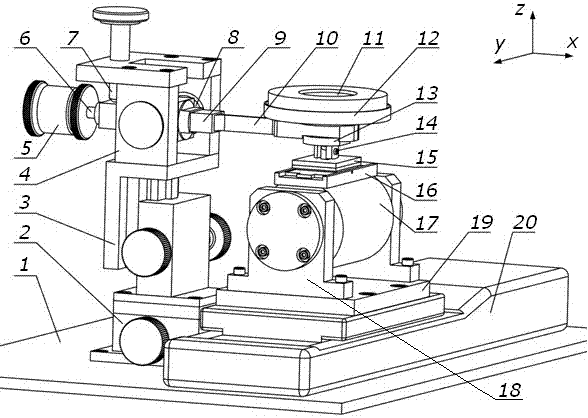

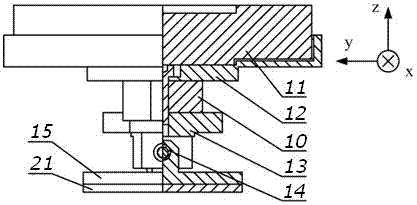

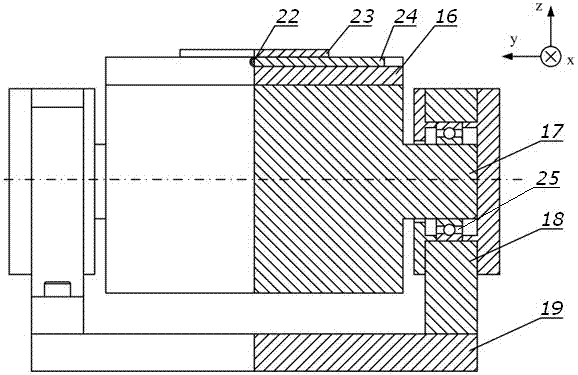

[0029] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an embodiment of the self-adjustable face-to-face reciprocating friction testing device of the present invention; the self-adjusting face-to-face reciprocating friction testing device includes a first cage 4, a strain beam 10, an upper clamp 15, a lower clamp 16, and a lower rotating shaft 17 , second cage 18, motion platform 19, reciprocating motor 20; Wherein, described lower clamp 16 is positioned at the below of upper clamp 15, and the bottom of described upper clamp 15 is provided with upper friction test piece, and described lower clamp 16 The bottom is provided with a lower fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com