Decontamination device for mechanical grill

A grid and machinery technology, applied in the field of environmental protection machinery, can solve problems such as unfavorable work efficiency, clogging of mechanical grids, high labor intensity, etc., and achieve the effect of facilitating centralized processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

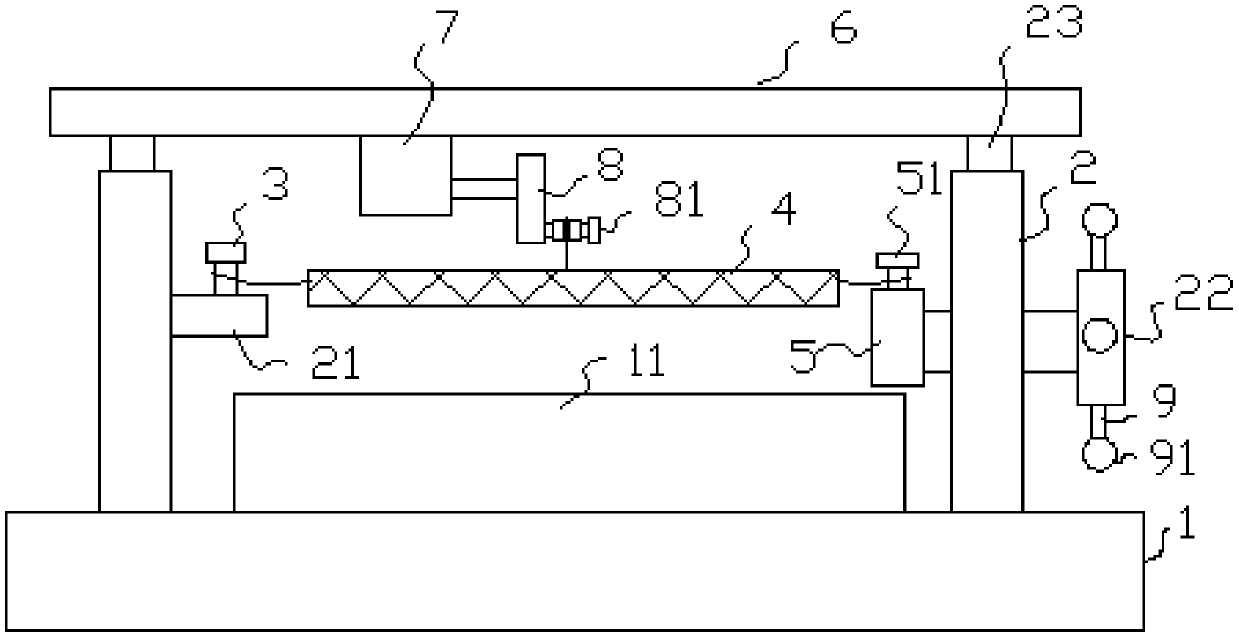

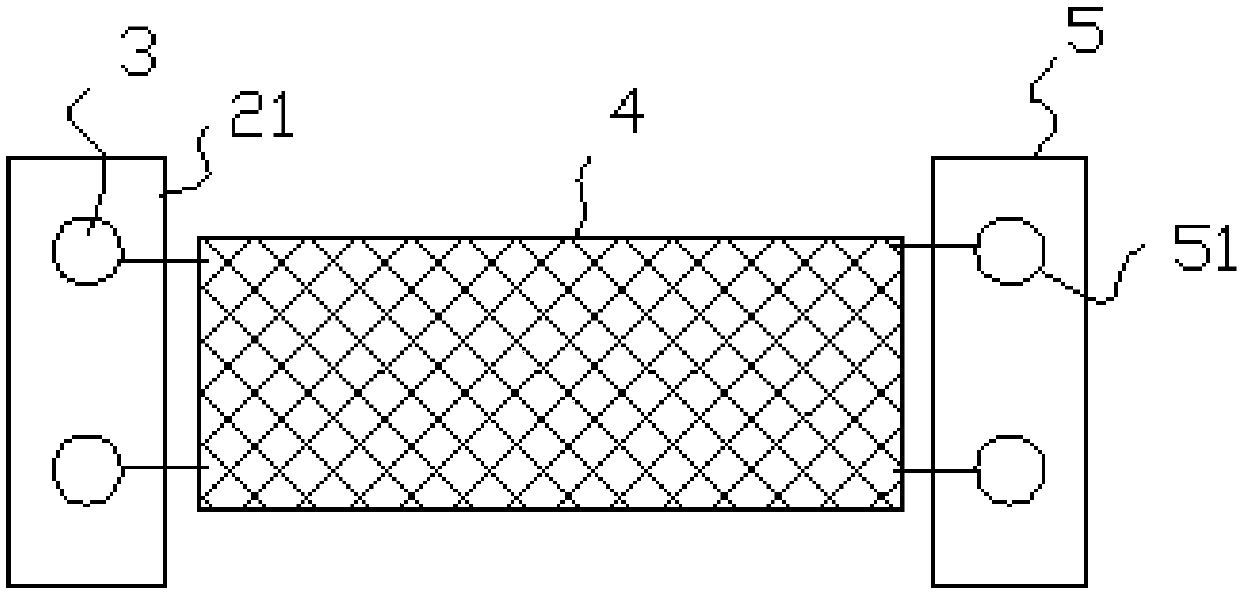

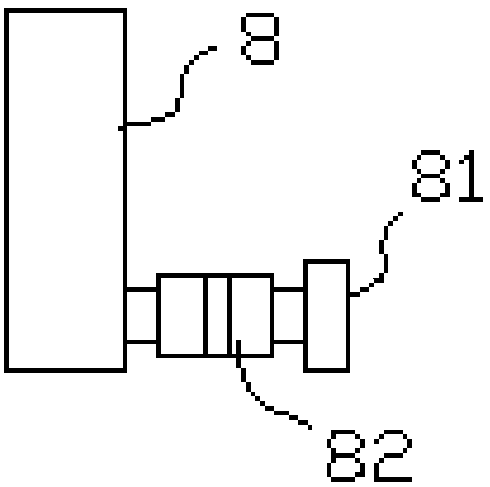

[0015] Such as Figure 1-Figure 3 As shown, a decontamination device for mechanical grille, its structure includes a base 1, a pair of vertical plates 2 are arranged on the base 1, and a support 21 is fixed on the right side of the vertical plate 2 on the left side. A pair of first fastening bolts 3 are screwed on the seat 21 . When in use, the left end of the mechanical grid 4 can be fixed together with the first fastening bolt by a wire rope, ready for the decontamination behind.

[0016] The vertical plate 2 on the right side is screwed with a screw rod 22 from outside to inside, and the inner end of the screw rod 22 is riveted with the fixed block 5 in rotation, and the second fastening bolt 51 is screwed on the fixed block 5 . When in use, the right end of the mechanical grille can be fixed together with the second fastening bolt through the steel wire rope, and the left and right positions of the fixing block can be adjusted by turning the screw rod together, so as to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com