Rotor wing device with rotating direction area changable function

A rotor and area technology, applied in rotorcraft, transportation and packaging, aircraft, etc., can solve problems such as backward blade stall, forward blade shock wave resistance, and limited rotor speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

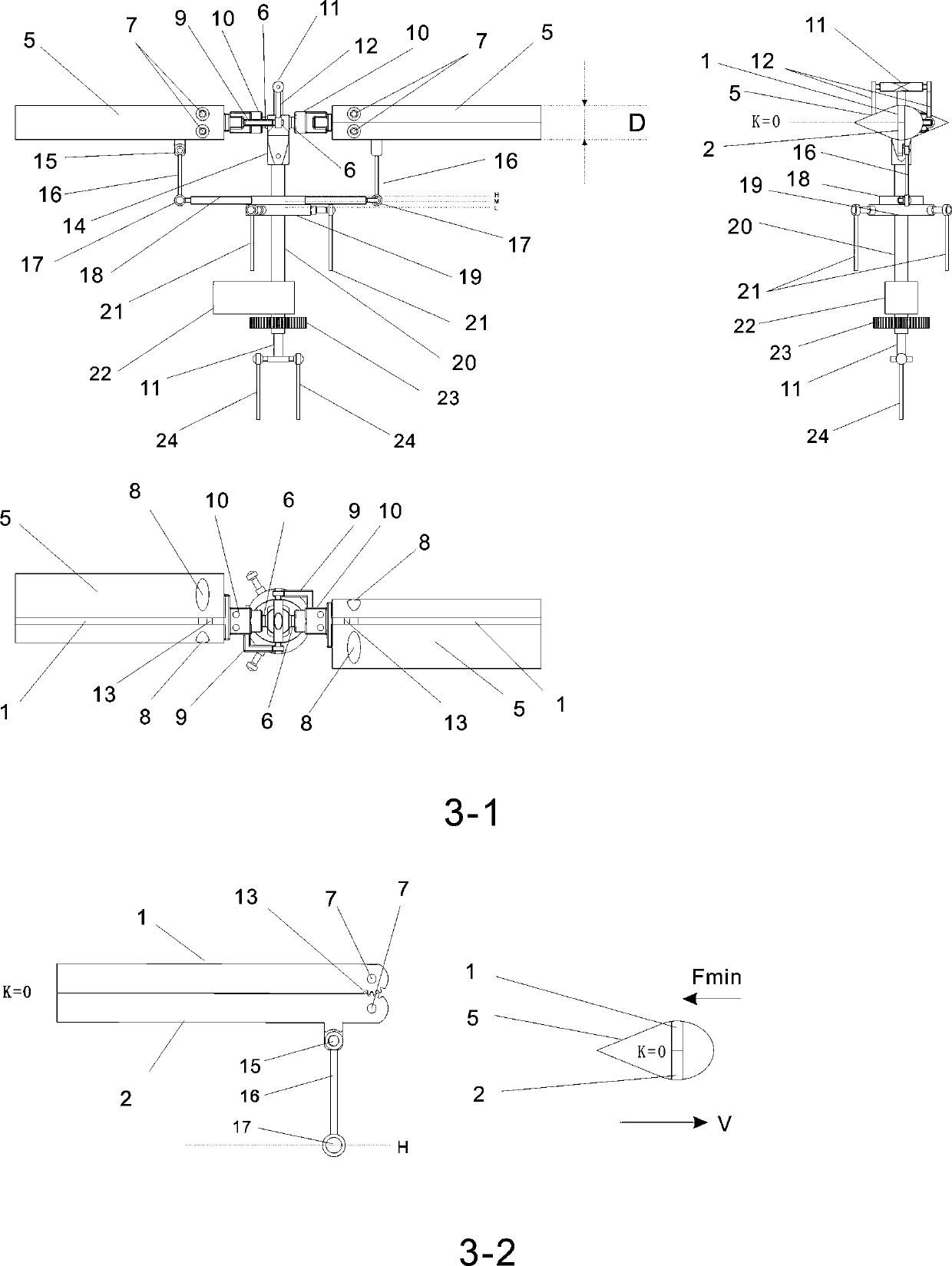

[0181] image 3 It is one of the embodiments of the present invention. The variable rotation area rotor device composed of the maximum thickness slotted blade is called the maximum thickness slotted variable rotation area rotor device. image 3 middle Figure 3-1 Three views of the device.

[0182] image 3 middle Figure 3-1 , The largest thickness slotted blade (5) is connected to the collective pitch shaft (6) of the hub (14) through the blade holder (10), the hub (14) is installed on the rotor main shaft (20), and the other A slotted blade with maximum thickness (5) is installed in the same way on the blade holder (10) on the other side with a phase difference of 180°. The rotor is composed of two slotted blades with maximum thickness (5), The rotor main shaft (20) is hollow. A collective pitch rod (11) is installed in the hollow rotor main shaft (20). The collective pitch rod (11) can be driven by the collective control rod (24) along the hollow rotor main shaft (20) The axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com