Adjustable friction damper

A technology of friction damper and friction pad, which is applied in the direction of building components, building types, shockproof, etc., and can solve the problem that the output tonnage of the damper cannot achieve the vibration reduction effect, the friction damper cannot eliminate energy, and strong vibration and weak vibration cannot be balanced. and other issues, to achieve the effect of good engineering practicability, low maintenance cost, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

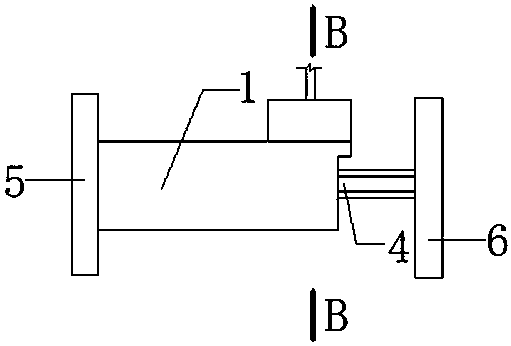

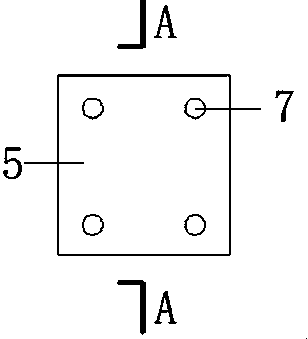

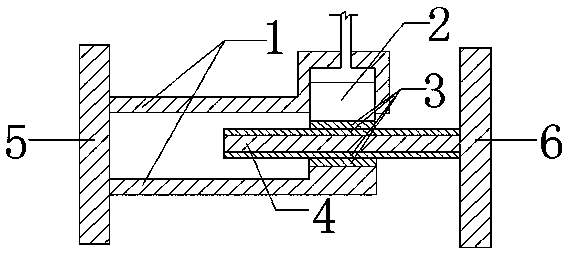

[0019] Embodiment 1: As shown in Figure 1-Figure 4, it is an implementation example of an adjustable friction damper of the present invention, which mainly includes an outer cylinder 1, a piston 2, a friction pad 3, a sliding plate 4, a left fixing plate 5, Right fixed plate 6 and reserved bolt holes 7.

[0020] The friction damper can be installed through the reserved bolt holes 7 on the left fixing plate 5 and the right fixing plate 6; the sliding plate 4 is parallel to the axial direction of the outer cylinder 1 to ensure that it can slide along the axial direction of the outer cylinder 1; the sliding plate 4 Friction pads 3 are arranged on both sides and the part in contact with the sliding plate 4, and the friction pads 3 can be replaced with corresponding materials according to different requirements. The adjustable friction damper changes the frictional force by changing the pressure of the piston on the sliding plate 4 through hydraulic pressure, so as to obtain differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com