Automatic calibration equipment of inclination survey sensors

An automatic calibration, sensor technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of troublesome operation, difficult data reading, multi-person collaborative operation, etc., to reduce errors, ensure quality, and improve test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

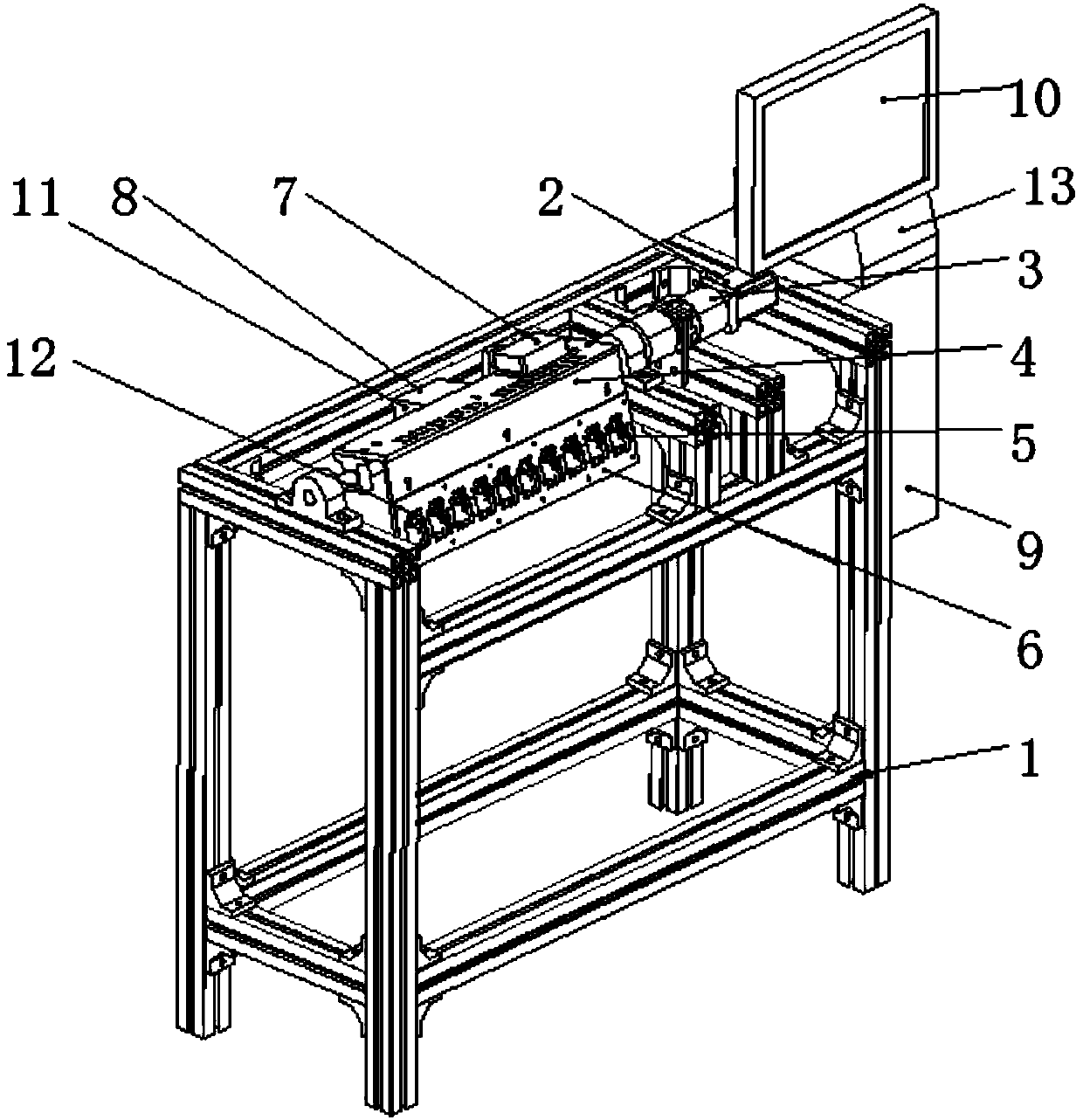

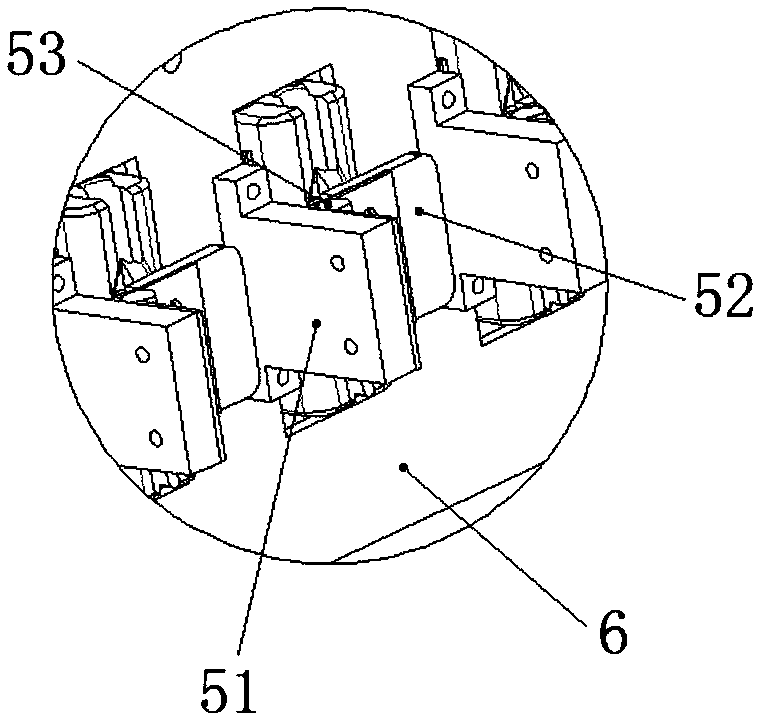

[0022] Such as figure 1 with figure 2 As shown, an automatic calibration device for an inclinometer sensor includes a frame 1, a calibration fixture, an inclinometer sensor 12, a high-precision inclination sensor 7, a data forwarding device 8, an electric control box 9, an industrial computer 10, a printer 13 and a rotating device. The calibration fixture is provided with an upper panel, a side plate 4, a limit plate 6 and a pressure plate 5. The side plate 4 and the upper panel are fixedly connected to form an inverted L-shaped structure. The limit plate 6 is located in front of the side plate 4, and the pressure plate 5 is located on the limit plate. 6 front, the limit plate 6 and the side plate 4 are formed with a number of grooves arranged side by side that match the size of the inclinometer sensor 12. The pressure plate 5 is provided with a fixed end 51 and a pressing end 52, the fixed end 51 is located outside the groove, and is perpendicular to the side plate 4, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap