Dedicated self-aligning mechanism for lens and concentricity adjusting device employing same

A lens and centering technology, applied in installation, optics, instruments, etc., can solve problems such as high cost, inability to guarantee adjustment accuracy, inconvenient adjustment operation, etc., and achieve less error influencing factors, simple and quick adjustment, and convenient concentricity adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

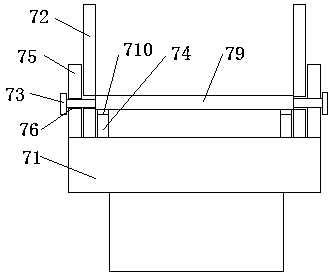

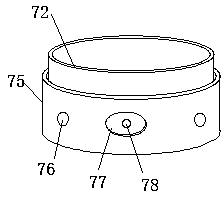

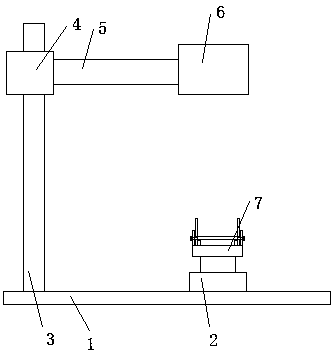

[0022] A lens-specific centering mechanism, such as figure 1 and figure 2 , comprising a support 71, a lens barrel 72 and a number of positioning bolts 73, the top surface of the support 71 is provided with an annular inner frame 74 and an annular outer frame 75, and an annular groove is formed between the annular inner frame 74 and the annular outer frame 75, and in the annular groove The end portion of the lens barrel 72 is provided, the top surface of the annular inner frame 74 is provided with a lens 79, and the lens 79 is arranged in the lens barrel 72, the diameter of the lens 79 is greater than the diameter of the annular inner frame 74, and the annular outer frame 75 is evenly arranged around A plurality of positioning holes 76, the positioning holes 1 76 are provided with internal threads, the lens barrel 72 is evenly surrounded by a number of positioning holes 2, the positioning holes 1 76 are correspondingly arranged with the positioning holes 2 one by one, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com