Method for controlling automatic adjustment of washing time of RO (reverse osmosis) water purifier

A technology of reverse osmosis water purifier and flushing time, applied in the direction of osmosis/dialysis water/sewage treatment, reverse osmosis, chemical instruments and methods, etc., can solve the problems of single curing of automatic flushing time, waste of water resources, etc., and achieve automatic flushing Reasonable control and the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

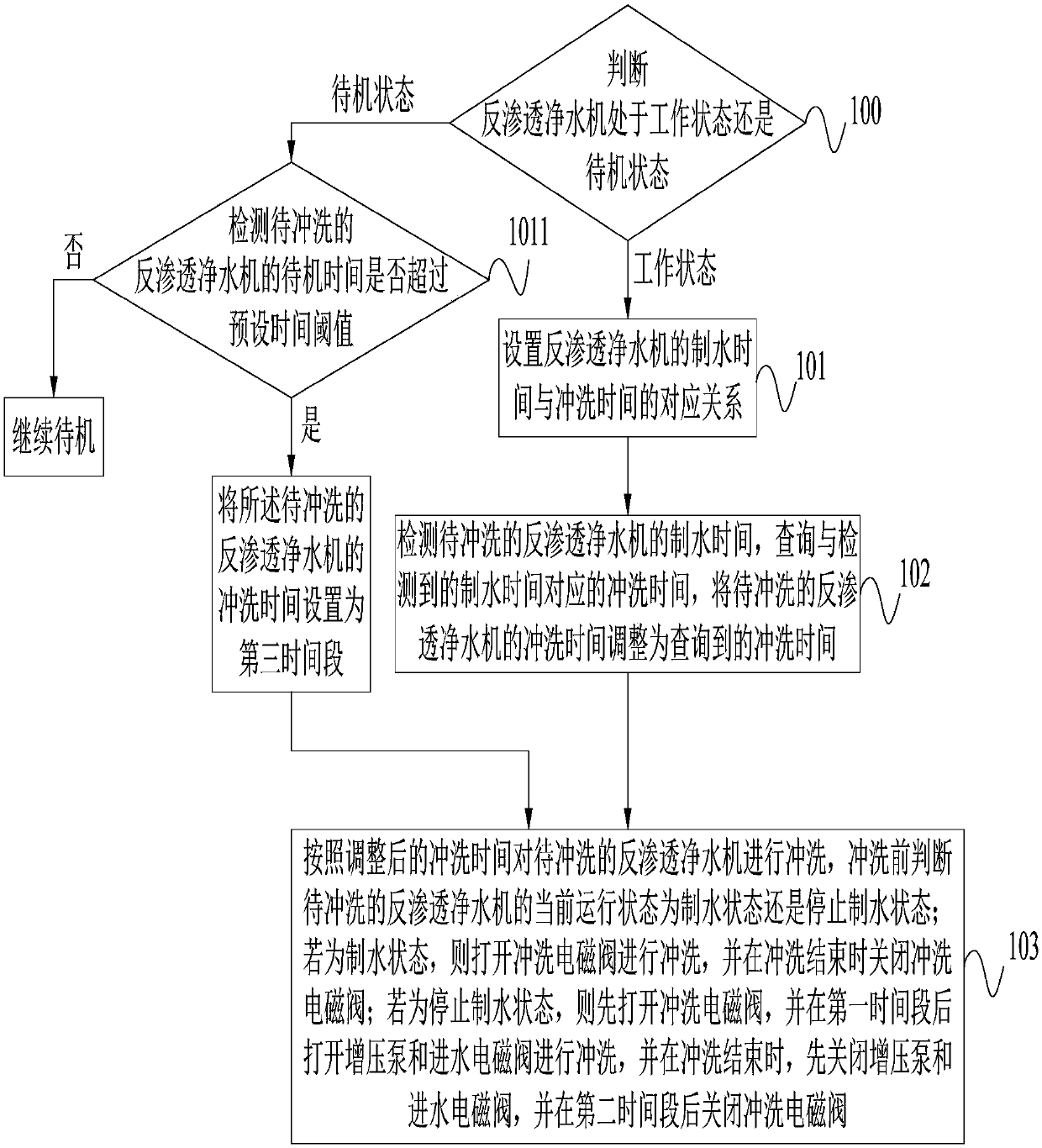

[0026] Such as figure 1 As shown, the automatic flushing control method of the reverse osmosis water purifier of the present invention comprises the following steps:

[0027] Step 100, judging whether the reverse osmosis water purifier is in the working state or the standby state, if it is in the working state, then execute step 101, if it is in the standby state, then execute step 1011;

[0028] Wherein, step 1011 is: detecting whether the standby time of the reverse osmosis water purifier to be flushed exceeds the preset time threshold, and if so, setting the flushing time of the reverse osmosis water purifier to be flushed to a third time period, and then Execute step 103, if not, continue to stand by;

[0029] Wherein, preferably, the preset time threshold is 3 days, and the third time period is 20 seconds, that is, if i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com