Ultrawater purifier for lab

A technology for ultra-pure water machines and laboratories, which is applied in non-polluted water treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Difficult cleaning and maintenance, etc., to achieve the effect of saving power and ensuring the effect of water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

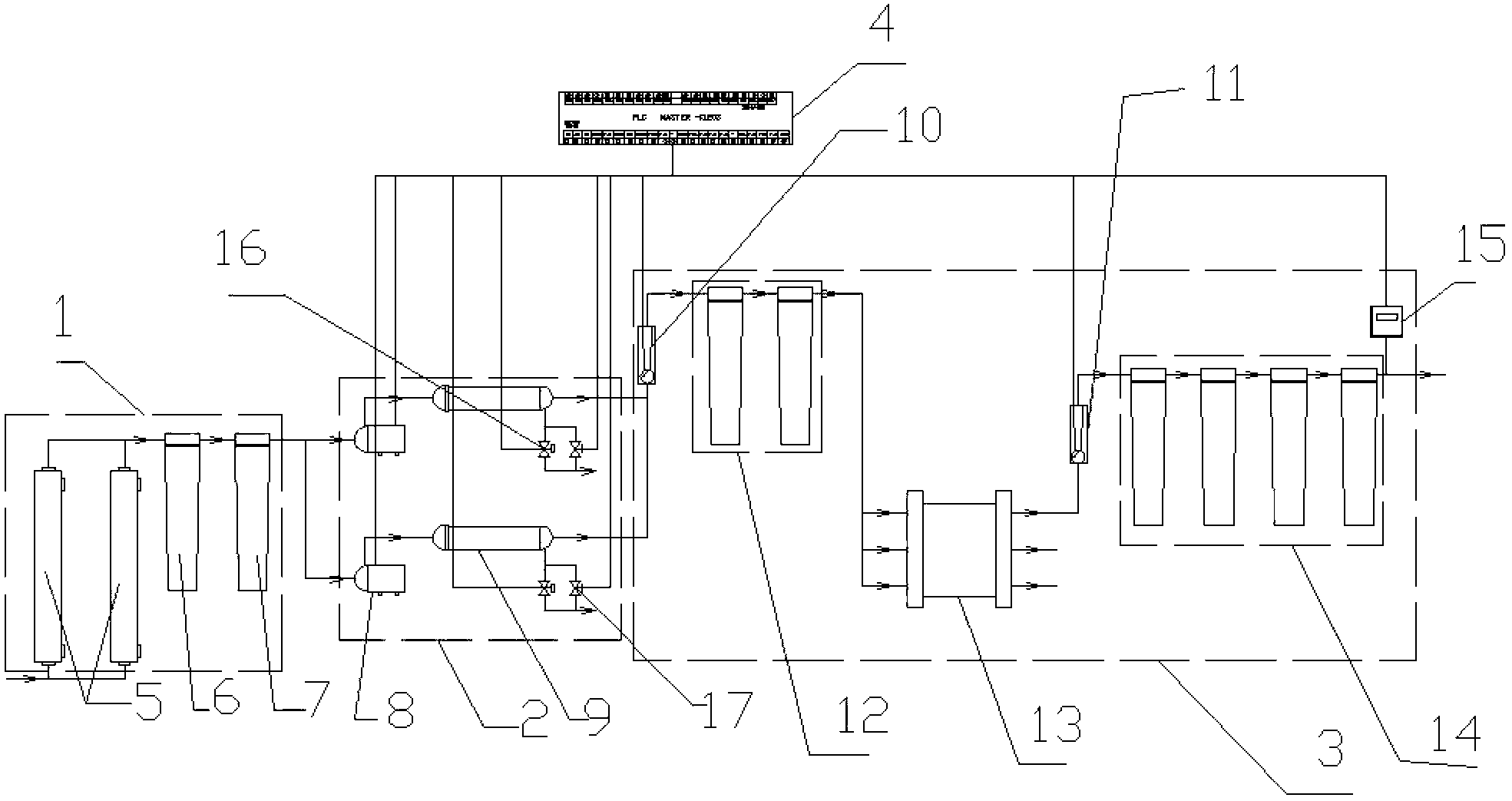

[0023] Such as figure 1 As shown, a laboratory ultrapure water machine of the present invention includes a pretreatment unit 1, several advanced treatment units 2 connected in parallel, a fine treatment unit 3, and an intelligent programmable control system 4; the pretreatment unit 1 Including several parallel ultrafiltration membrane modules 5, microfiltration membrane modules 6, activated carbon filters 7, several parallel ultrafiltration membrane modules 5 are connected to the microfiltration membrane module 6, the microfiltration The membrane assembly 6 is connected with the activated carbon filter 7; each of the advanced treatment units 2 includes a series diaphragm pump 8 and a reverse osmosis membrane assembly 9, and the diaphragm pump 8 of each of the advanced treatment units 2 is connected to the The activated carbon filter 7 of the pretreatment unit 1 is connected; the fine treatment unit 3 includes a first flow meter 10, a softening column assembly 12 formed by conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com